Lumber Dry Kiln Wood Heat Options

Dry Kiln Heat Options:

Some of the most economical heat options for a wood drying kiln include using wood residue, including sawdust, shavings, chips, and bulk wood.

Lumber Dry Kiln Wood Heat Options |

Dry Kiln Heat Options: Some of the most economical heat options for a wood drying kiln include using wood residue, including sawdust, shavings, chips, and bulk wood. |

Sasmo Pellet and Corn Burner |

Sasmo Corn and Pellet Burner: This unit burned waste seed corn into a vertical boiler. The low pressure steam was used in a double expansion steam engine to drive both a feed-pump (boiler water) and 2 kW generator. |

Waterwide Solid Fuel Burner at Austral Ply in Brisbane Australia |

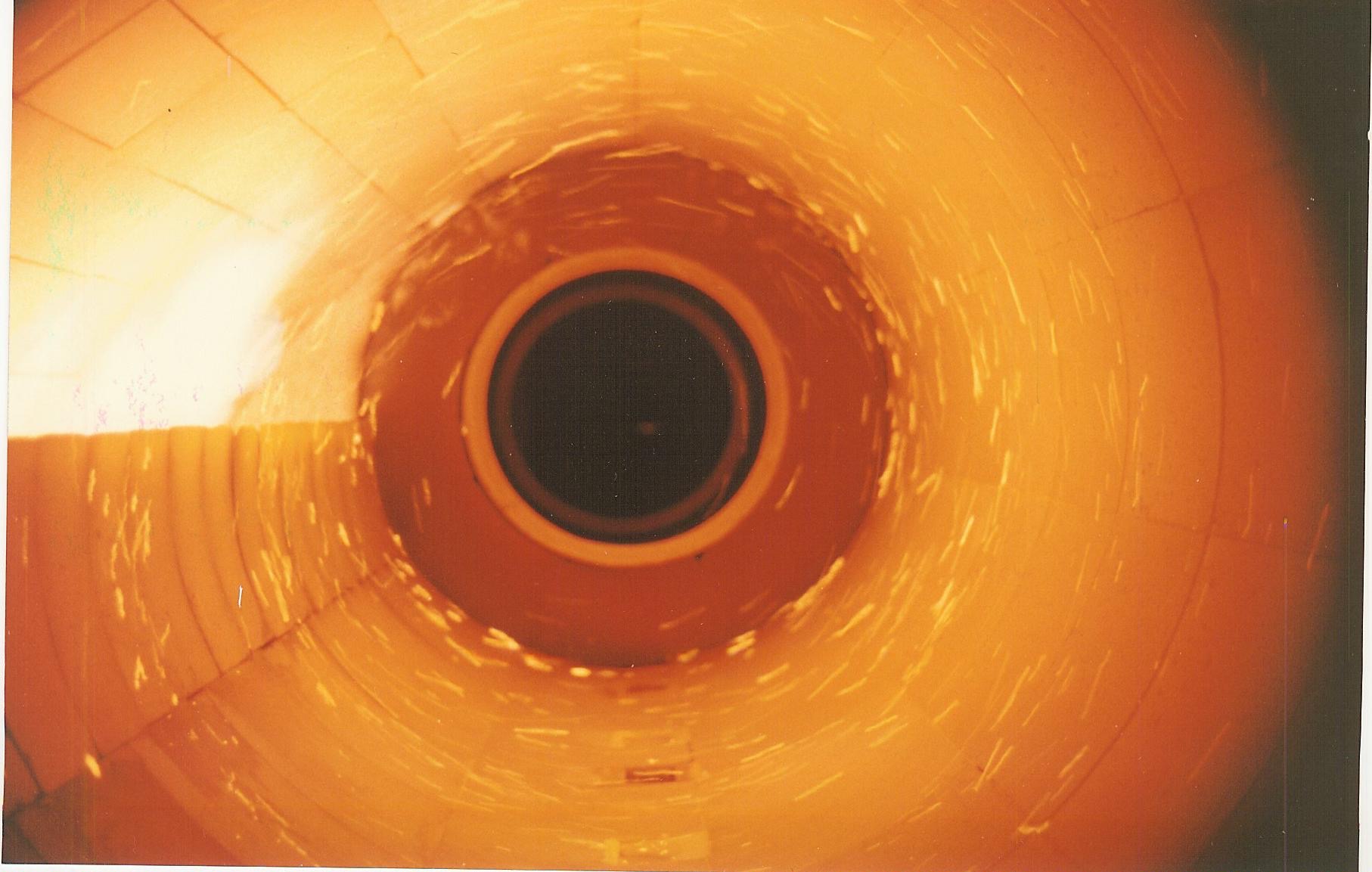

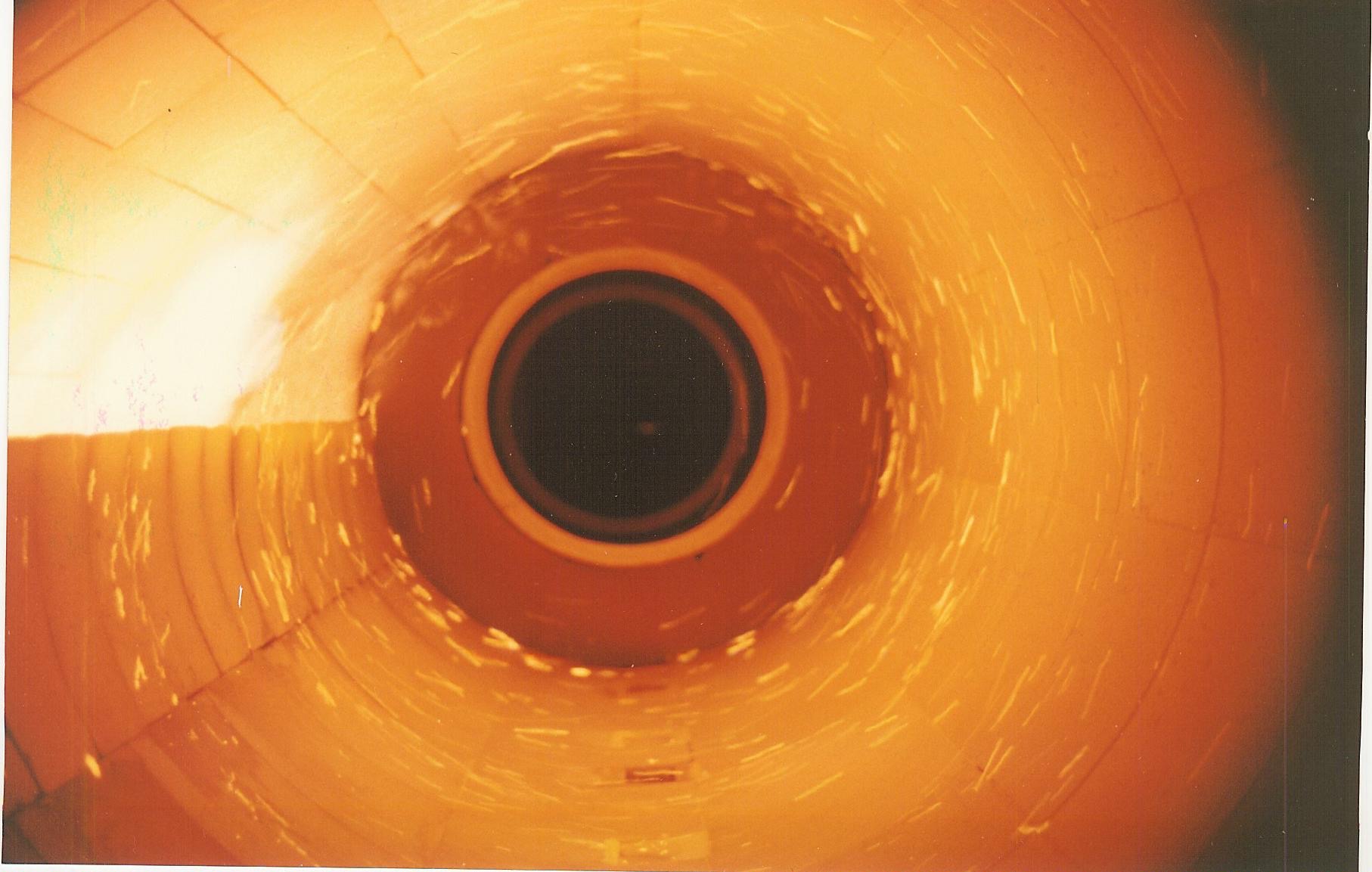

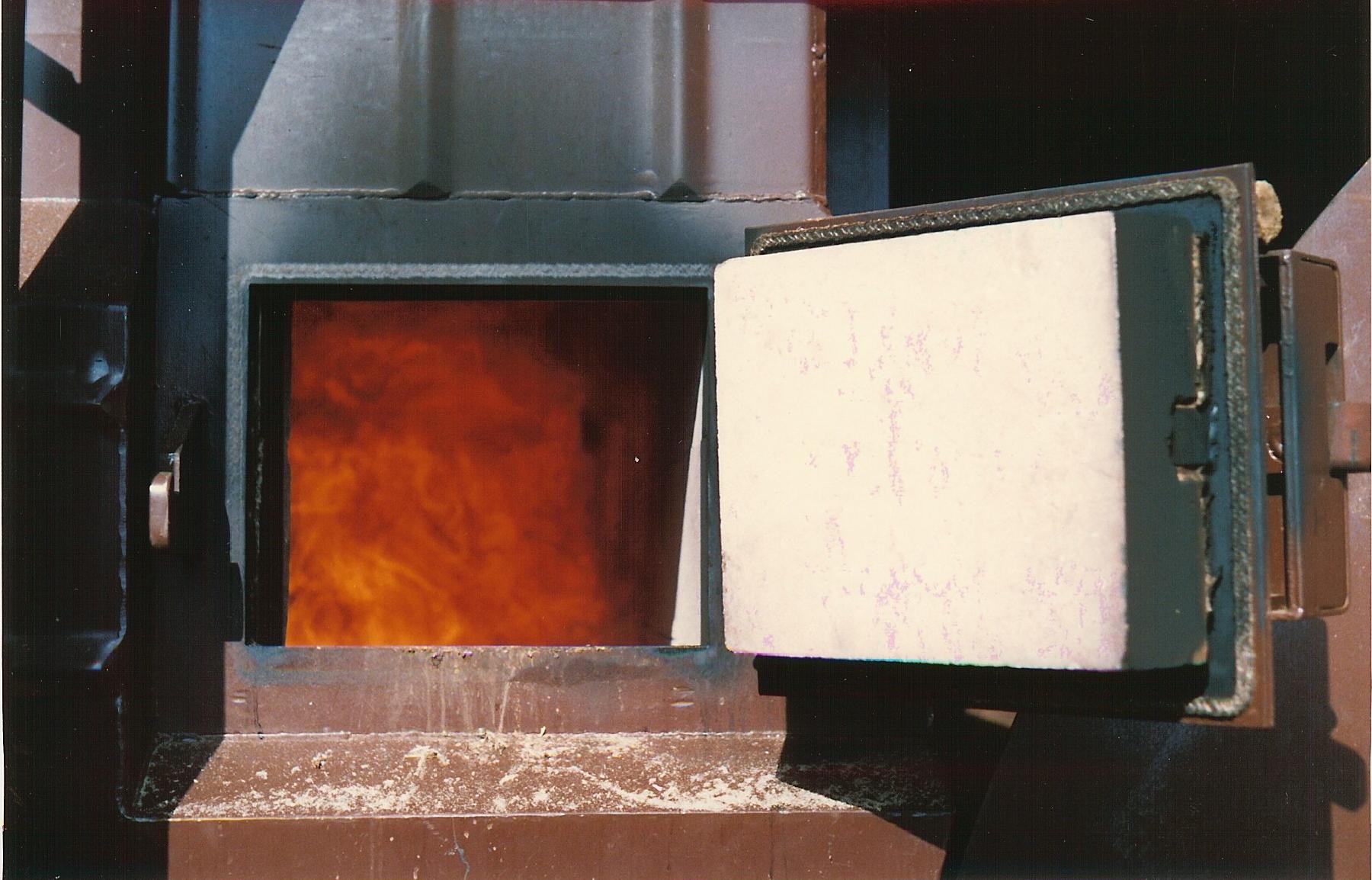

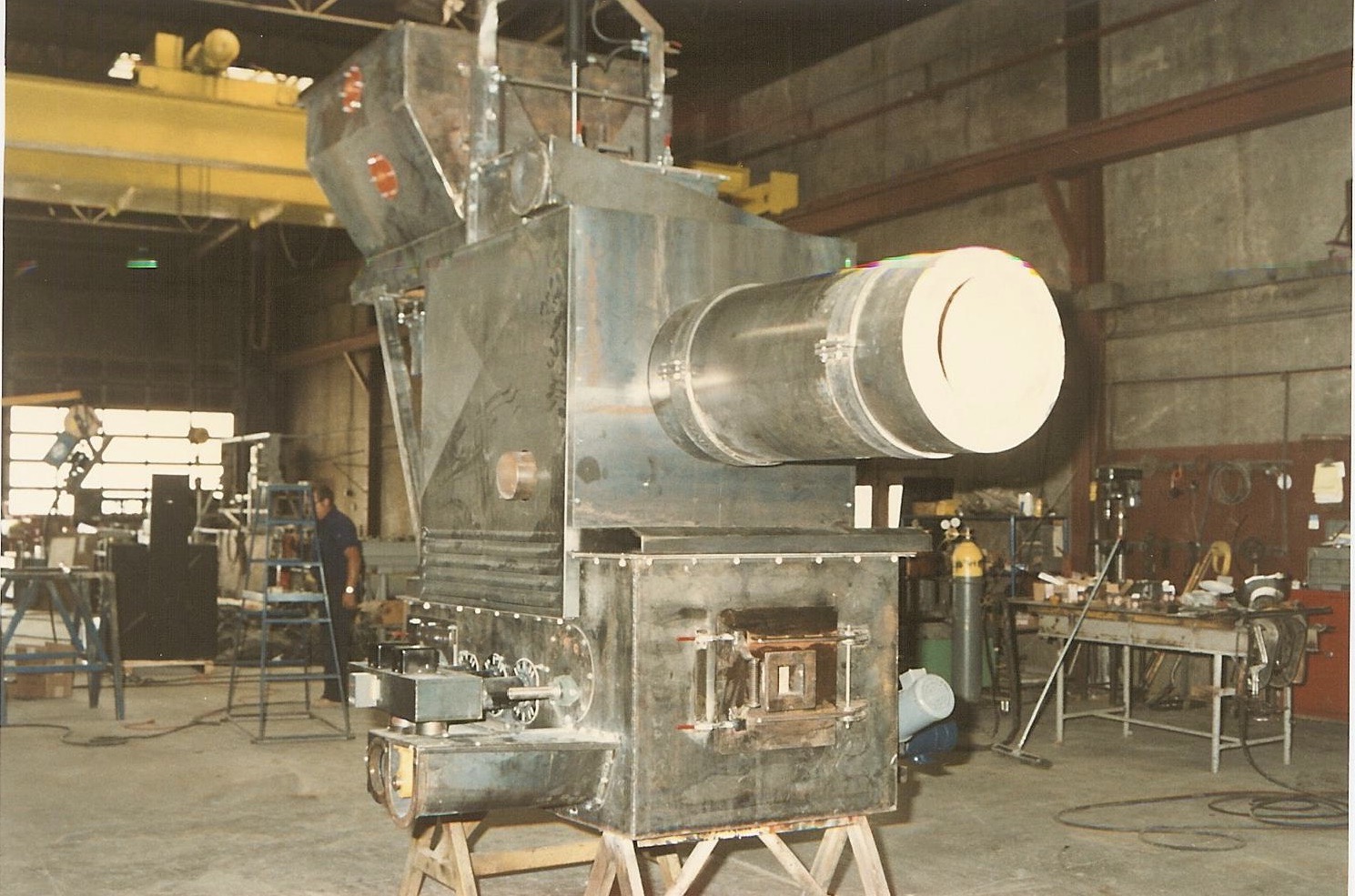

Waterwide Solid Fuel Burner (Hastings, New Zealand): The Waterwide unit was popular in the 1980’s and used all over the world for grain drying, wood/timber drying, and sawdust dryers. The company had a sales and licensing agreement to bring the technology into the USA by a company in Erie, PA called Skinner Engine Company, in 1989 to sell and distribute solid fuel burners in the USA (they lasted less than a year then cancelled those plans). I installed and sold several of these in Australia and the USA. In Australia, the larger units were used to direct fire plywood dryers in plywood mills. The thin laminates were lathed off a spinning log of Radiata Pine. The thin sheets of sweet smelling wood were then put through a direct fired continuous dryer. The sheets were then laminated together and pressed to make plywood. The thin off-cuts were shredded and the waste wood was stored in large bulk storage silos. The most costly part of the solid fuel system was the fuel handing and storage. The solid fuel burner worked great, with cyclonic combustion of the gas. The hot gas was filtered through high temperature low micron filters (called a baghouse). The hot gas then was mixed with ambient air to cool a bit, then routed to the dryers. In the USA, the model DF80 (3 million btu/hr rating) was the most popular. |

Waterwide Solid Fuel Burner |

Waterwide Solid Fuel Burner (Hastings, New Zealand): The Waterwide unit was popular in the 1980’s and used all over the world for grain drying, wood/timber drying, and sawdust dryers. The company had a sales and licensing agreement to bring the technology into the USA by a company in Erie, PA called Skinner Engine Company, in 1989 to sell and distribute solid fuel burners in the USA (they lasted less than a year then cancelled those plans). I installed and sold several of these in Australia and the USA. In Australia, the larger units were used to direct fire plywood dryers in plywood mills. The thin laminates were lathed off a spinning log of Radiata Pine. The thin sheets of sweet smelling wood were then put through a direct fired continuous dryer. The sheets were then laminated together and pressed to make plywood. The thin off-cuts were shredded and the waste wood was stored in large bulk storage silos. The most costly part of the solid fuel system was the fuel handing and storage. The solid fuel burner worked great, with cyclonic combustion of the gas. The hot gas was filtered through high temperature low micron filters (called a baghouse). The hot gas then was mixed with ambient air to cool a bit, then routed to the dryers. In the USA, the model DF80 (3 million btu/hr rating) was the most popular. There is a DF80 for sale by Lundell Manufacturing in Wisconsin as of December 15, 2021. Waterwide Solid Fuel Smokeless Burner Article (pdf) |

Biomass Burner Wood Fired for Lumber Dry Kilns Used at Paxport Mills in Tacoma, Washington |

Biomass Burner Biomass Burner originally produced in Sterling, Colorado. |

Furnace Type Kiln for Lumber and Firewood Drying Using Wood Wastes by the USDA Forest Products Lab |

Furnace Type Lumber Dry Kiln 1945 From the USDA in 1945 (yes, you read right). We've tried these heat pipe kilns and they work great. In the more modern version, we used a Conifer sawdust burner to direct fire heat into a large diameter stainless steel pipe in the top section of the kiln, where the fans circulate the airflow over the pipe to heat the kiln. The fans always stay on (especially when the direct fire burner is operating).The basic concept is to have the output of the biomass burner go directly into a heat pipe. Just think of a long horizontal steel chimney that heats the kiln. You can also use propane or natural gas burners to do the same thing. All the gases are contained within the steel pipe, so it reduces the change of any flammability issues. Furnace Type Lumber Dry Kiln (pdf) |

Stainless Steel Pipe for Lumber Dry Kiln Direct Fired Heat |

Heat Pipe The Furnace Type Kiln was originally tested out by the Forest Products Lab in 1945 in Madison, Wisconsin. |

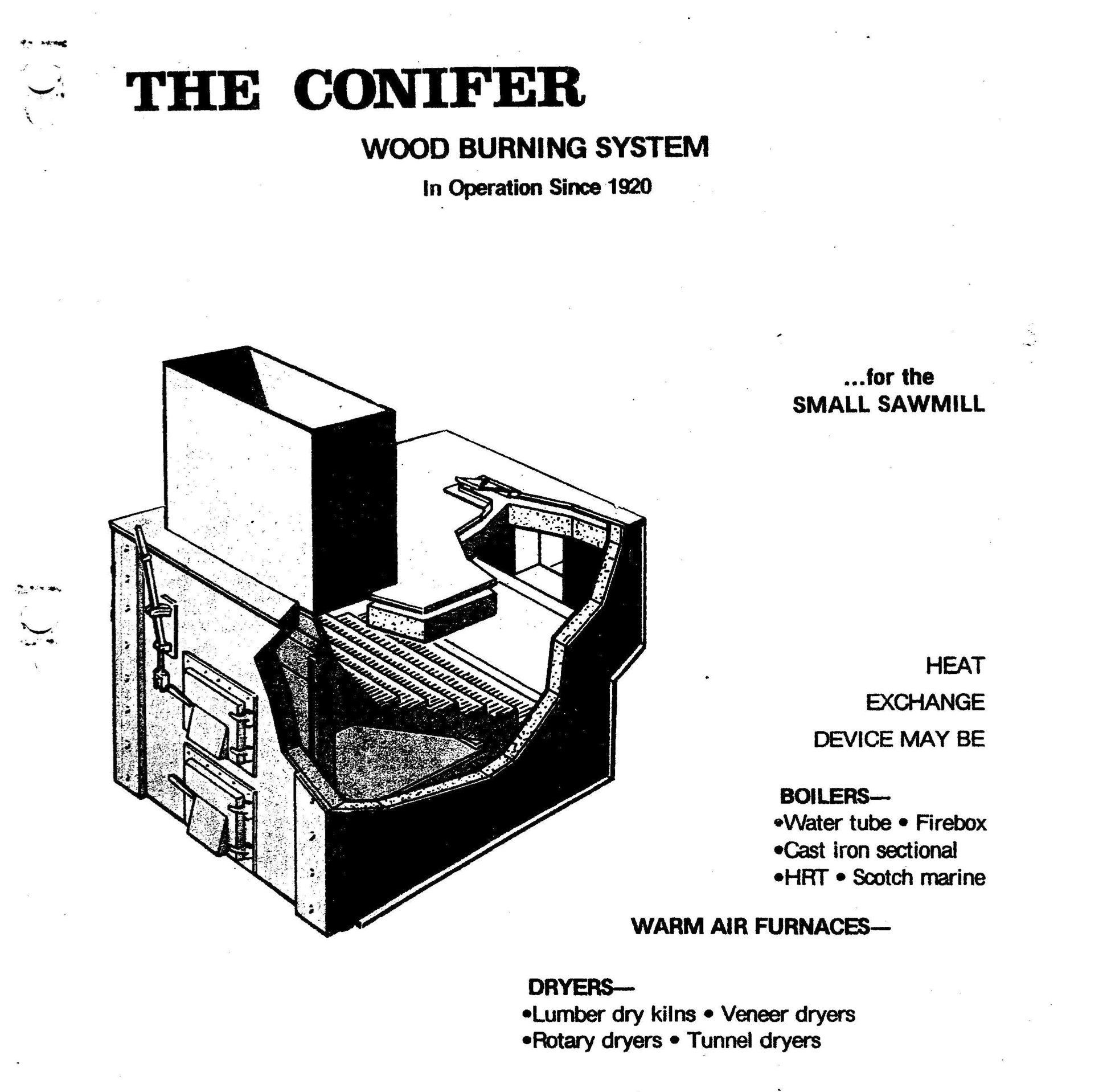

Conifer Sawdust Burner |

The Conifer Sawdust Burner The Conifer has been around for a long time. We build one from a kit in 1992 for our original 15,000 BF kiln, here in Madison, Wisconsin (sold to a customer in Michigan).The kit was basically cast iron plates which were assembled with poured ceramic material and ceramic fire bricks. The Conifer is great for direct-fired kilns and sawdust burners which exit into biomass boilers or long stainless steel pipes (see Forest Products Lab Furnace Type Kiln). Conifer Sawdust Burner |

Conifer Sawdust Burner |

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP | PDF | Free Tesla Supercharger Miles |