1-10 MW Prime Power Supercritical CO2 for Data Centers | Silent Power

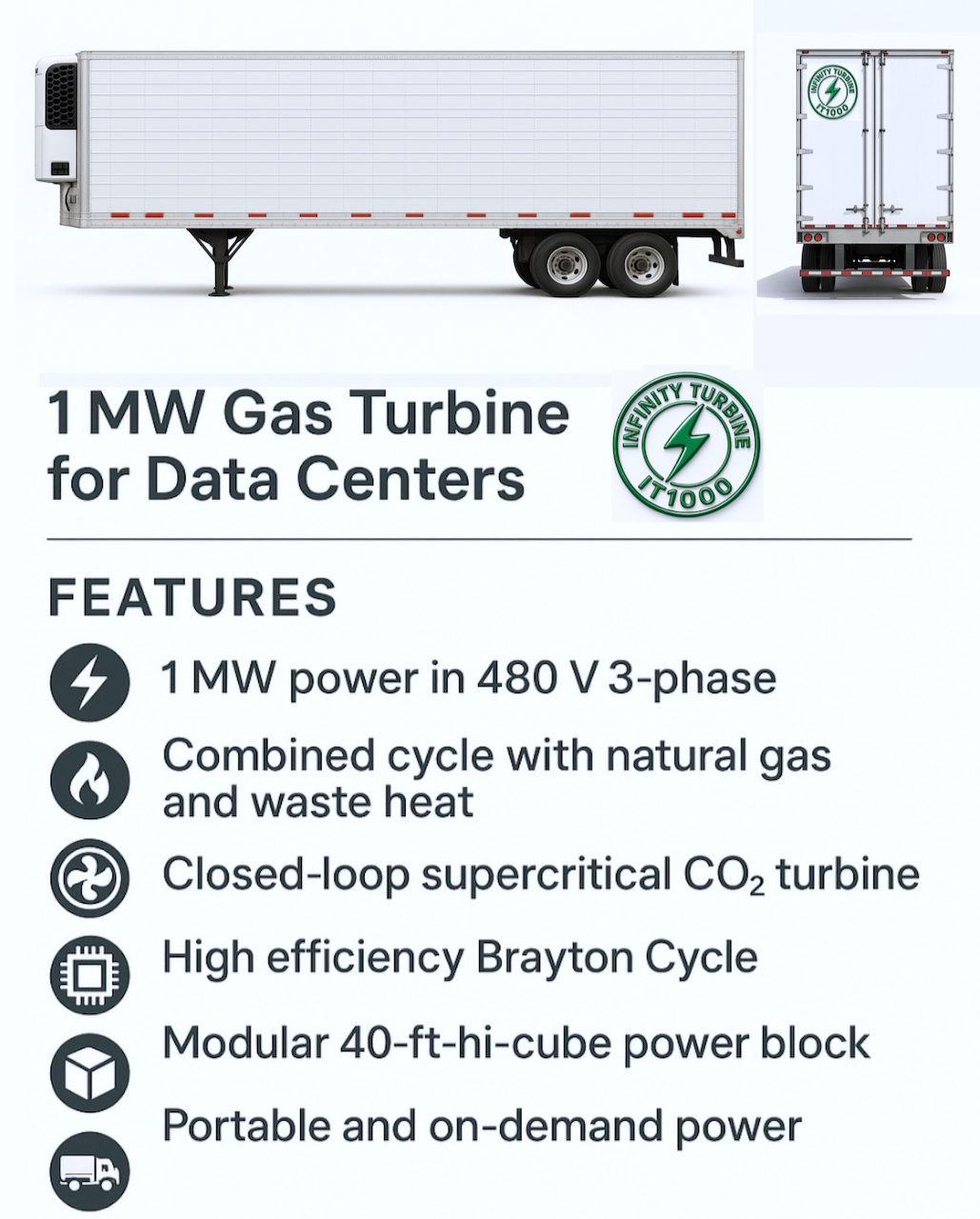

IT1000 Natural Gas 1 MW Power Block (also available IT250 and IT10 MW)

Global Energy Sales | Plans | Consulting TEL: 1-608-238-6001 Email: greg@globalmicroturbine.com

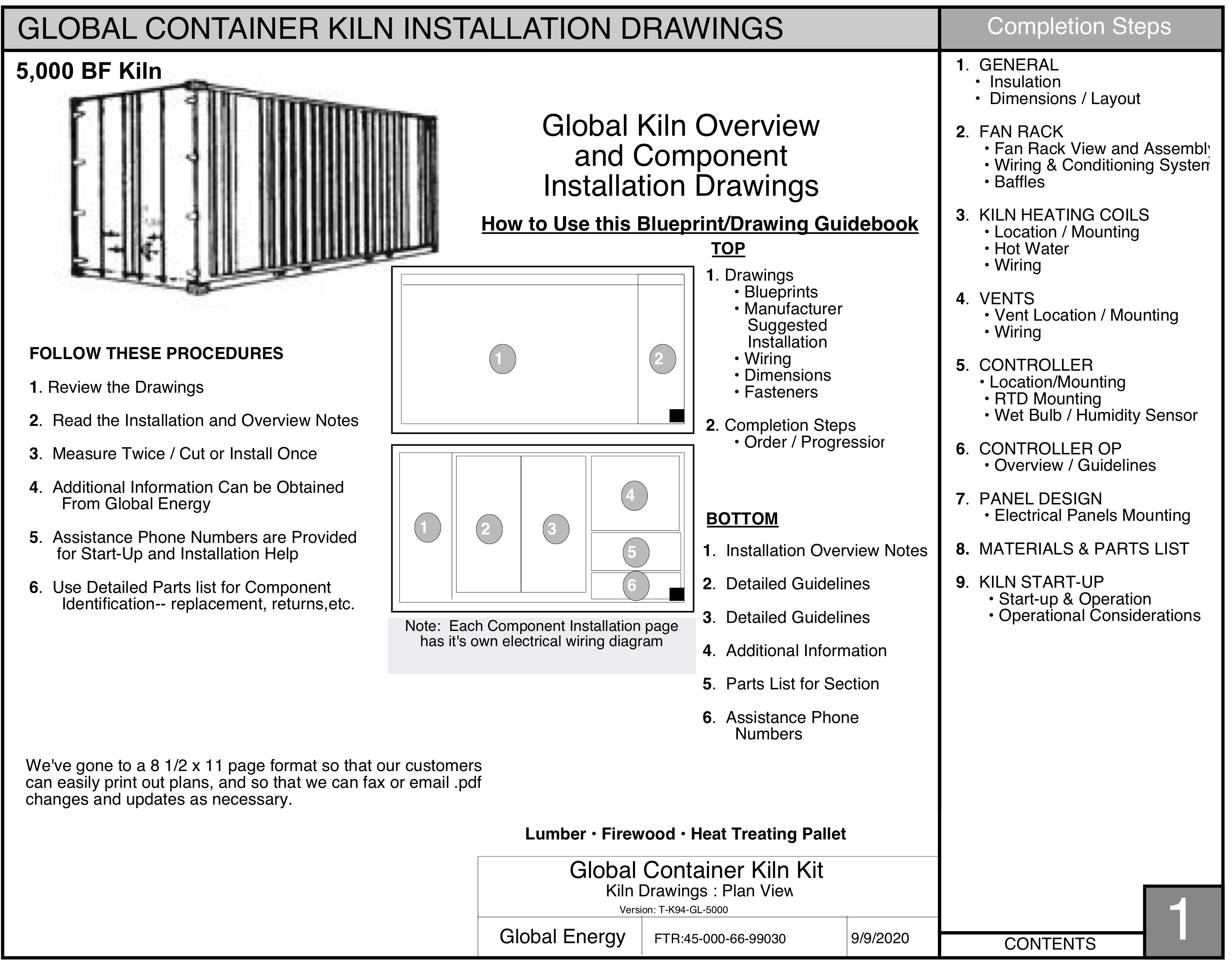

5000 BF Kiln for Lumber and Firewood Plans, parts, or full build using natural gas, propane, or wood heat via heat pipe or hot water... More Info

15000 BF Kiln for Lumber and Firewood Plans, parts, or full build using natural gas, propane, or wood heat via heat pipe or hot water... More Info

1-10 MW Prime Power Supercritical CO2 for Data Centers | Silent Power IT1000 Natural Gas 1 MW Power Block (also available IT250 and IT10 MW) |

Global Container Kiln Kit since 1992 for kiln drying firewood, lumber, and timbers for high value added products including heat treating and insect free firewood |

|

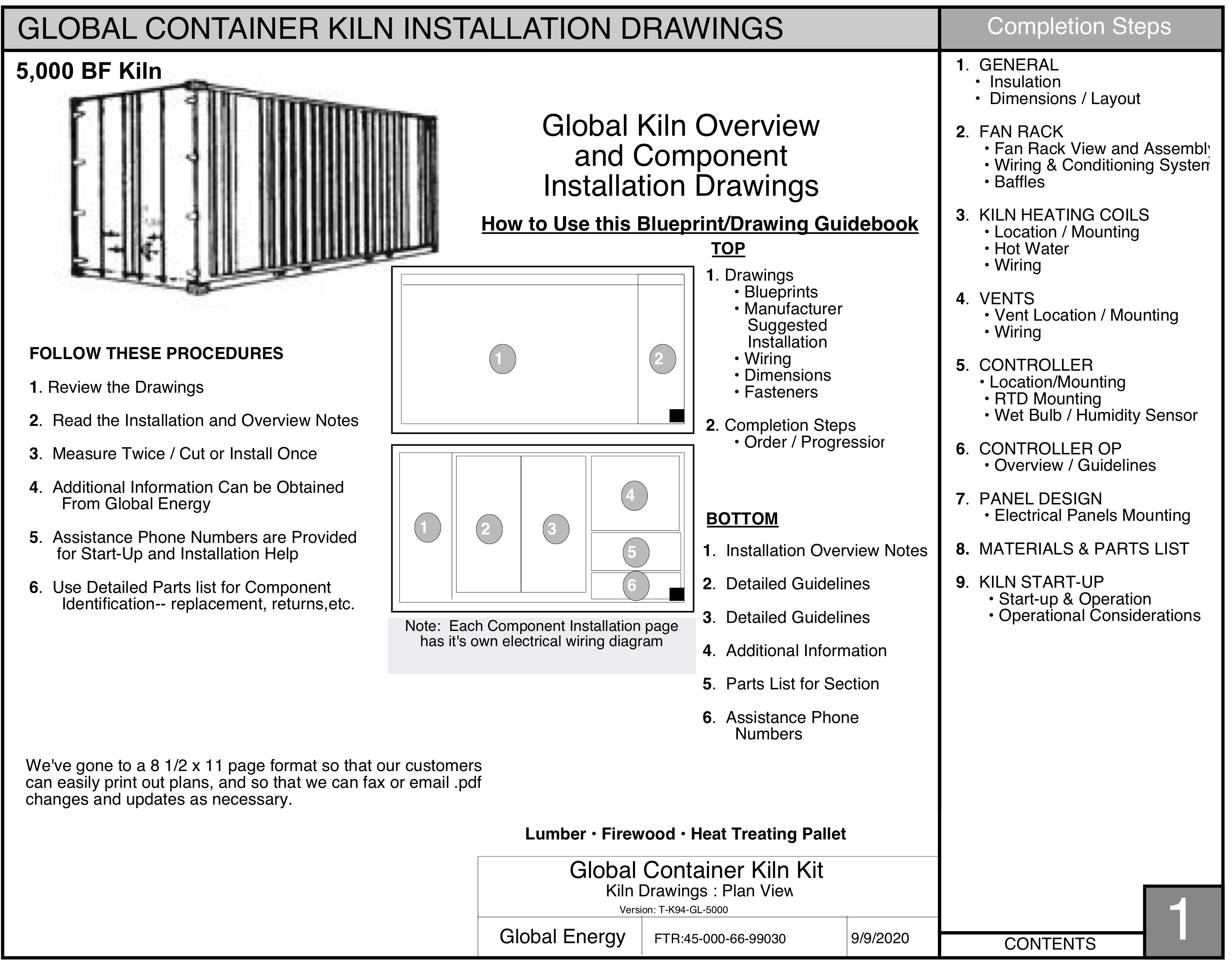

Unlock the Value of Kiln-Dried Lumber and Firewood Drying with the Original Container Kiln System In 1992, Global Energy pioneered the first container-based dry kiln, giving portable sawmill owners, furniture makers, and small shops a powerful way to add value through high-quality, kiln-dried lumber. After three decades of proven performance—and countless imitators validating its profitability—we are now making our original container kiln plans available. Build your own commercial-grade drying system and tap into the premium hardwood market with confidence.Email: Plans, Parts, Consulting, or Build Sample Pages of the 5000 BF Container Lumber Kiln Plans List by Global Energy Sample Pages of the 15000 BF Container Lumber Kiln Plans List by Global Energy |

|

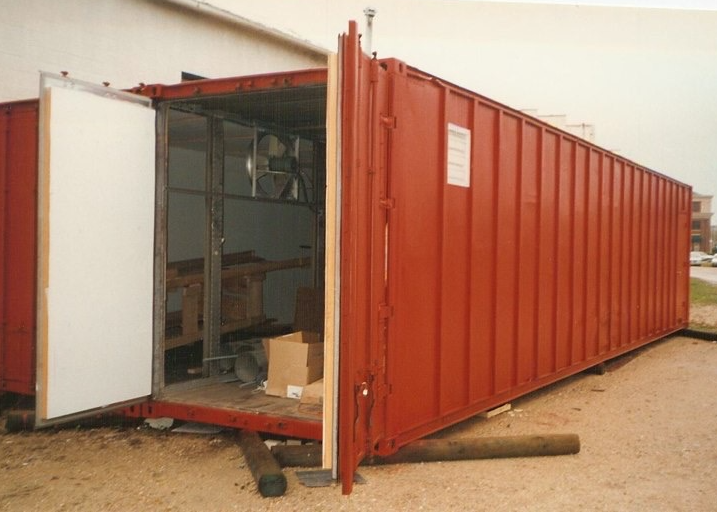

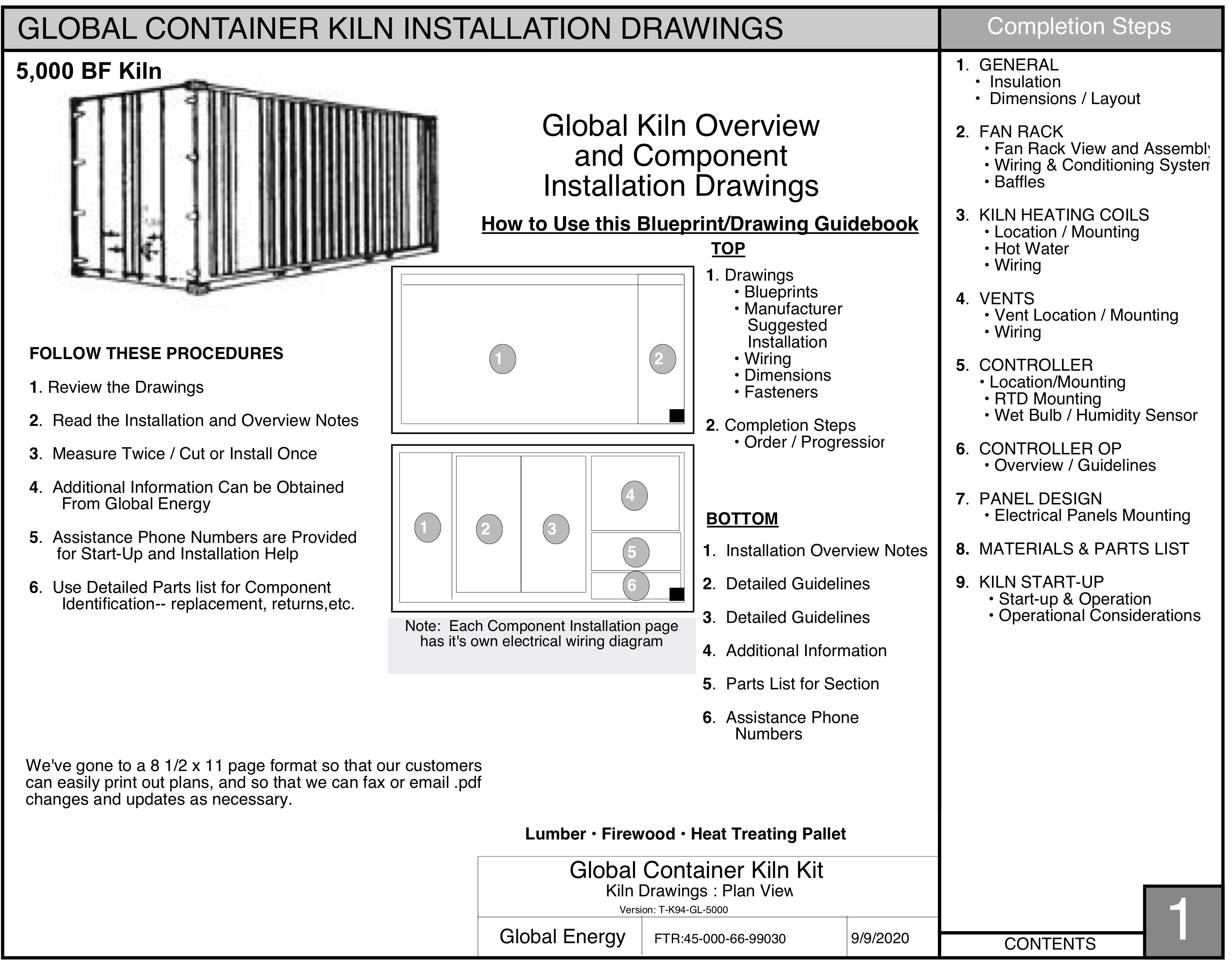

Build a Proven 5,000-Board-Foot Container Kiln for Lumber or Fast 4-7 Cord Firewood Drying Our 5,000 BF container kiln is built around a standard 40-foot high-cube aluminum shipping container or refrigerated van—an evolution of the original 15,000 BF kiln we designed in 1992 that delivered outstanding performance. As a firewood kiln, it holds roughly 4 to 7 cords and loads easily using IBC tote baskets and a simple rail system. Heat-treat cycles can be completed in just a few days, depending on your heat source. Dump firewood from your processor direct into baskets ready for kiln drying.This system introduced several industry-first innovations, including a furnace-type direct-fired heat pipe and a Conifer sawdust burner. Today, you can choose from multiple heating options such as a wood-fired water stove, gas boiler, indirect wood-fired heat pipe, or even a gas turbine.DIY fan packages start at sixteen thousand dollars.Contact us for plans, parts, consulting, or turnkey builds.Firewood Dry Kiln Wood Heat Options by Global Energy Sample Plans of the 5000 to 15000 BF Container Lumber Kiln by Global Energy |

Global Energy 15000 BF shipping container lumber dry kiln plans |

Scale Up with the 15,000-Board-Foot Container Kiln System or 14 Cord Firewood Kiln Our 15,000 BF container kiln is built using two 40-foot high-cube aluminum shipping containers or insulated refrigerated vans set side by side. This design traces back to the original 1992 kiln—a 15,000 BF unit constructed from used high-cube containers that delivered exceptional performance and set the standard for modern container kilns.As a firewood kiln, the system accommodates approximately 7 to 14 cords. Using a forklift, operators can load IBC tote baskets onto a simple rail system for fast, efficient handling. Depending on your chosen heat source, heat-treat cycles can be completed in just a few days.Heating options include a wood-fired water stove, gas boiler, indirect wood-fired heat pipe, or even a gas turbine.DIY fan kits start at $32,000.The original 1992 build introduced several groundbreaking innovations, including a sixteen-inch stainless direct-fired heat pipe and a Conifer sawdust burner—features that helped define this kiln as a proven workhorse for lumber and firewood producers. |

Global Energy 5000 BF shipping container lumber dry kiln plans |

Global Energy shipping container lumber dry kiln from 1992 |

|

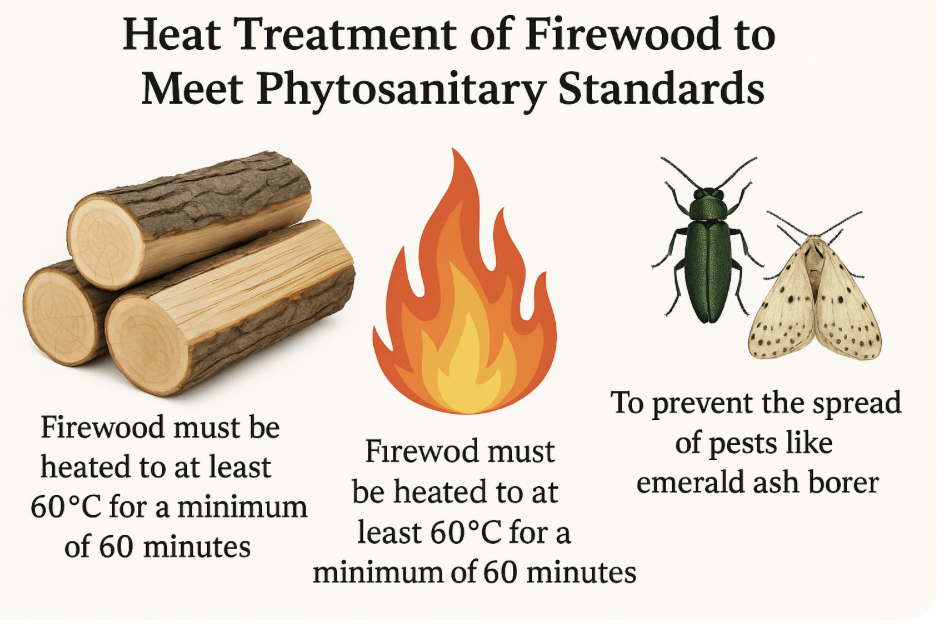

USDA Heat Treatment of Firewood to Meet Phytosanitary Standards Discover how certified heat treatment stops pests in their tracks and keeps firewood moving across state lines. This quick read breaks down the required temperatures, the gear that proves compliance, and real kiln case studies from the field. Learn what to monitor, how to pass inspections, and how producers can protect forests while staying in business. Read the full article to see the step by step process and results. |

|

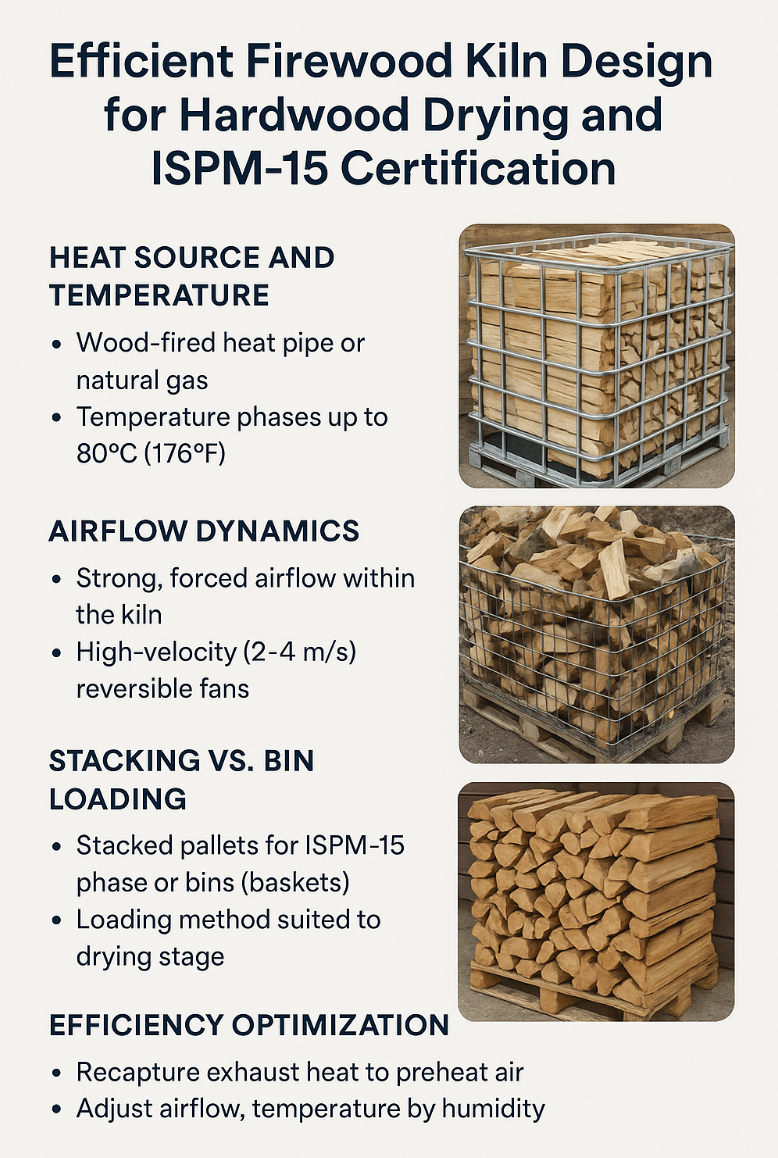

Efficient Firewood Kiln Design for Hardwood Drying and ISPM-15 Heat Treatment Certification to Eliminate any Insects Drying firewood efficiently requires a careful balance of airflow, temperature, and heat source economy. For hardwoods such as oak, the objective is to reach a final moisture content below 10% while maintaining conditions suitable for ISPM 15 heat treatment (minimum 56 °C / 133 °F core temperature for at least 30 minutes).By combining strong forced airflow, controlled heat application, and proper wood arrangement, kiln operators can significantly reduce drying times while minimizing fuel costs.Efficient Firewood Kiln Design for Hardwood Drying and ISPM-15 Certification |

|

Comparison of ISPM-15 and USDA Firewood Heat Treatment Standards Learn the difference between ISPM-15 and the USDA’s firewood heat treatment standards. This quick guide explains why firewood requires higher temperatures, longer treatment times, and stricter monitoring than wood packaging materials. Discover how these two systems work together to stop invasive pests like the emerald ash borer and protect forests at both national and international levels.Comparison of ISPM-15 and USDA Firewood Heat Treatment Standards |

|

|

Small Diameter Wood Processing for High Value and Large Profits Explore the profitable and sustainable opportunity of small diameter wood processing. Learn how innovative technologies and market demand are transforming this underutilized resource into valuable products, driving both economic growth and forest health.Infinity Turbine and Global Energy (inventor of the Container Kiln in 1992) are developing small diameter wood sawmill and vacuum bag drying kiln.We are currently looking for a micro sawmill manufacturer and partners to distribute and license our new products.Small Diameter Wood Processing Information and Opportunities |

|

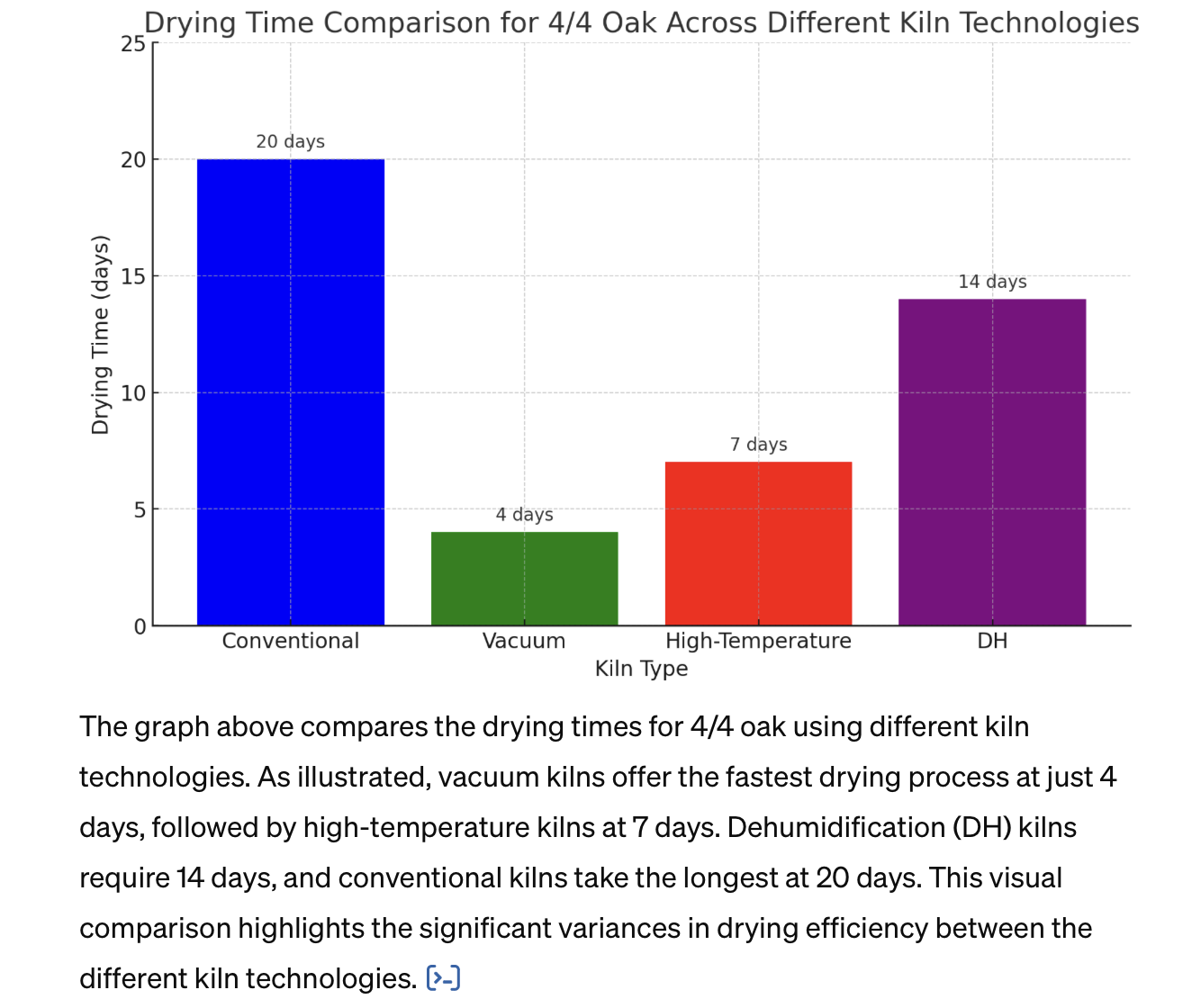

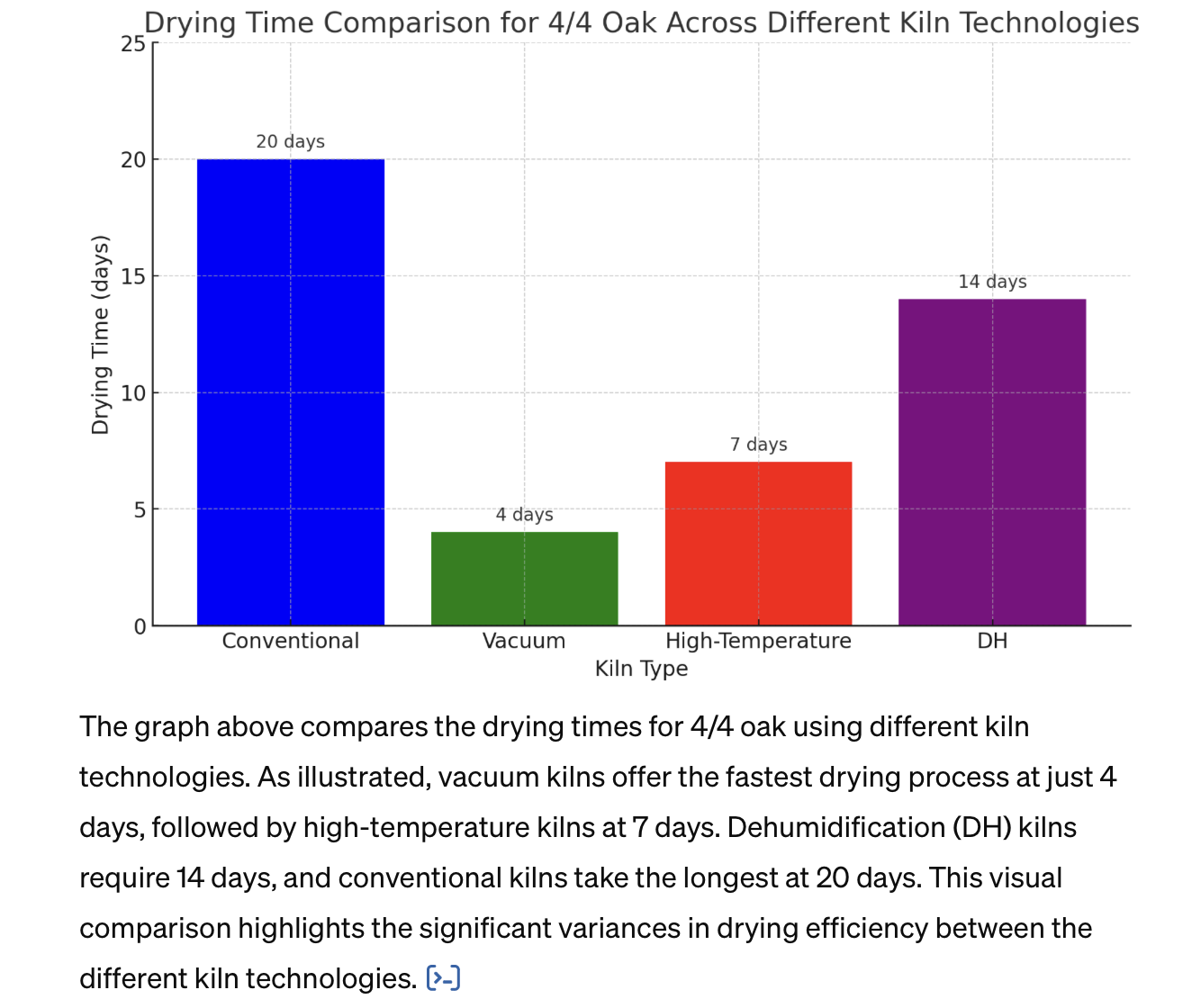

Lumber Dry Kiln Technologies: A Comprehensive Comparison The process of drying lumber is critical in woodworking and lumber production, significantly affecting the quality, stability, and usability of the wood. As technology advances, various lumber dry kiln technologies have been developed, each with its unique advantages and disadvantages. This article provides a comprehensive comparison of the main types of lumber dry kiln technologies: conventional kilns, vacuum kilns, high-temperature kilns, and dehumidification (DH) kilns, among others. |

|

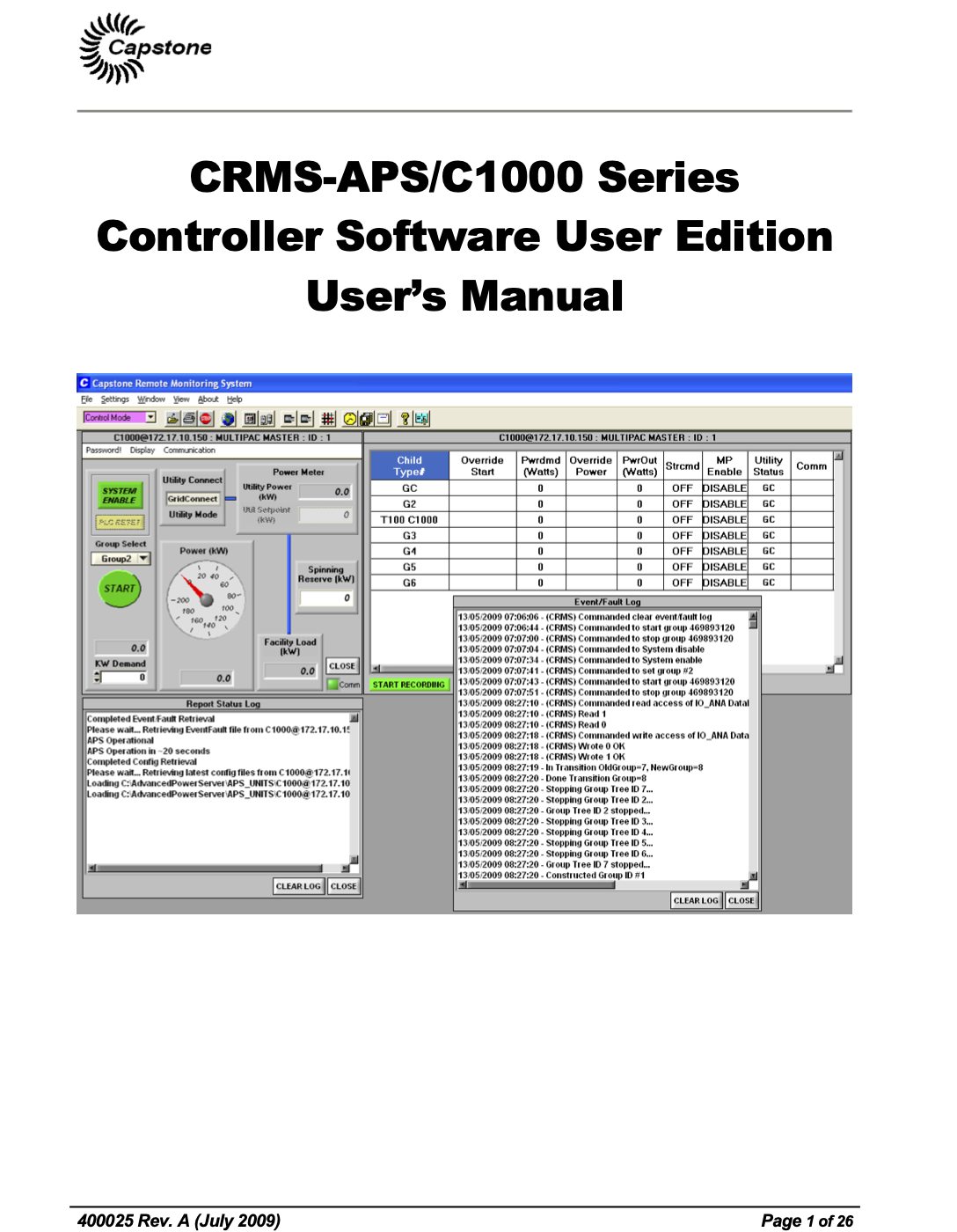

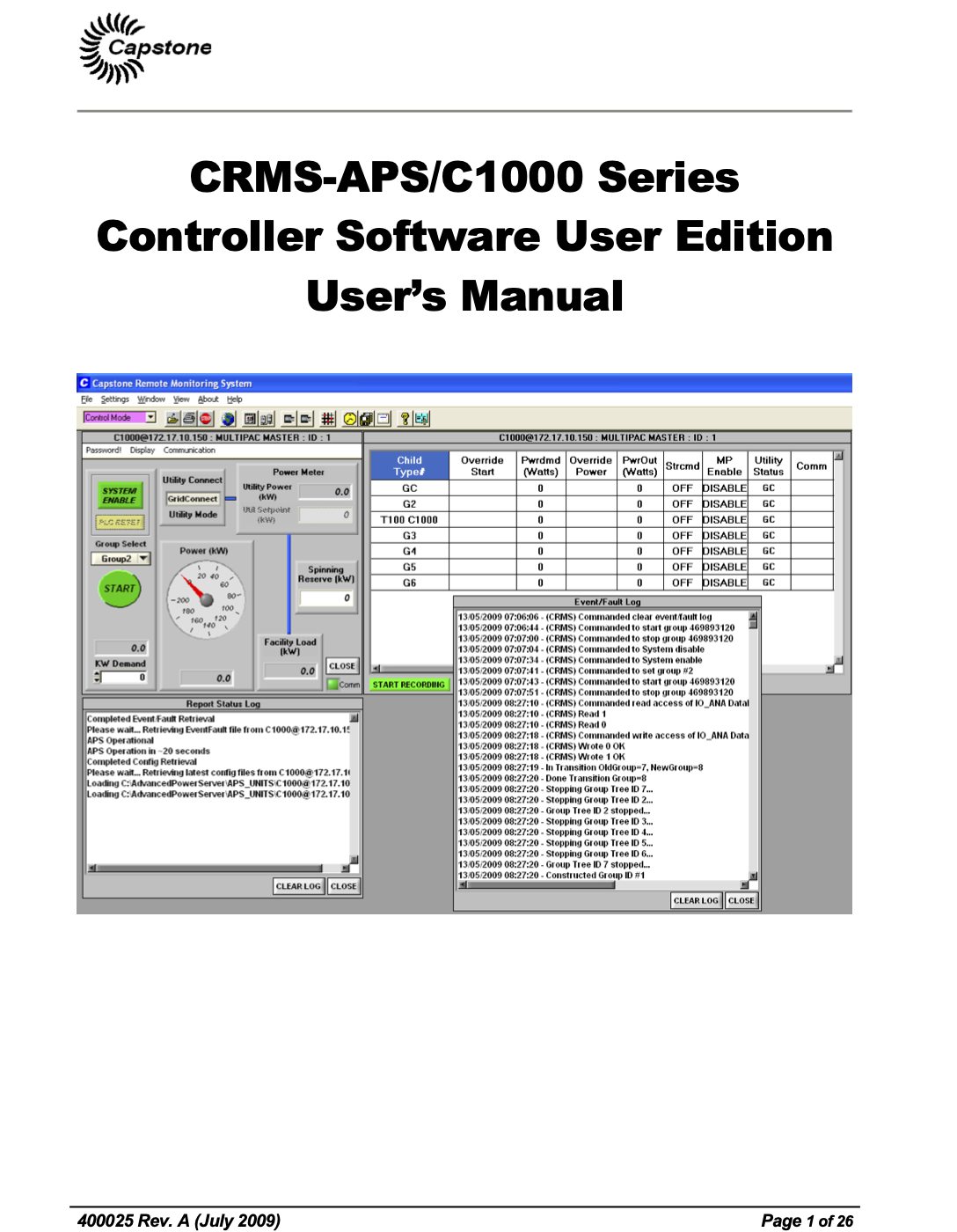

400025A CRMS APS User Edition UM2009 and CRMS Maintenance Software |

Capstone Remote Monitoring Software (CRMS) V4.25 and CRMS 551 and CRMS APS for C1000 V220 The Capstone Remote Monitoring Software allows users and maintenance to query the Capstone engine via a serial port interface. This software includes: Engine Software: C30, C60, C65, C200,ES0325_DPC_User_Maint_Comm_MaintCopeland Training V1.0 2001CRMS V4.0-4.25, 551 Maint, V4 User,V540Setup, Maintenance, UserCapstone Remote.msiCRMS-APS for C1000 MaintV220revACRMS Engine Software has been confirmed working as of 15 April 2024 on a Windows computer. Includes software and password. The software is outdated, and available as-is. The software is available for purchase. Email for pricing. This is a must-have item if you have a older Capstone (pre-2015).Email: Capstone Engine Software Pricing |

Parts Page of App |

Capstone Turbine Suppliers and OEM Parts OEM parts for Capstone Turbine C30, C60, C65, C200, C600 (3 x C200), C800 (4 x C200), C1000 (5 x C200).The app for basic part descriptions is free, and a detailed supplier contact list is available for a fee.The savings on buying direct from the OEM is huge, when compared to buying from Capstone or its dealer network.With over 14,000 microturbines manufactured since 2001, there is a need for parts.Free Version: • Search OEM partsPaid Version: • Search OEM parts • Available supplier information is listed • Button to email supplier • Button to call supplier• Save page page for future reference and quick find |

|

|

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | AMP | PDF |