|

History of Global Energy Since 1985

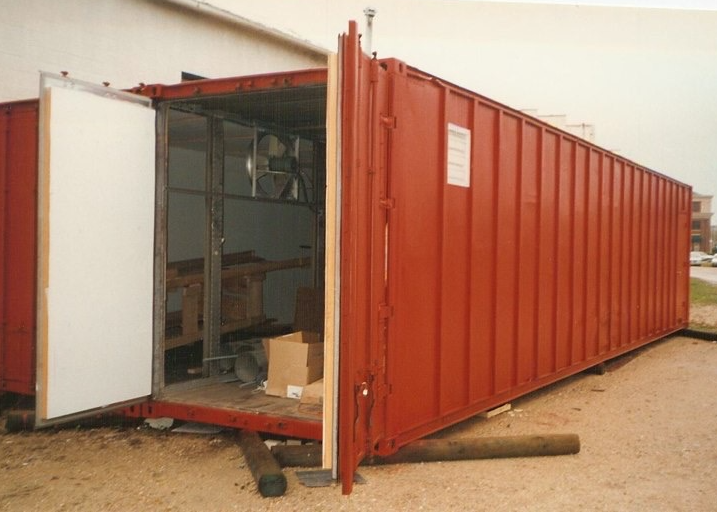

Infinity Turbine LLC is pleased to announce its consulting and analyst services.Energy: Since 1985, I have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. A wide breadth of subjects and project development includes some of the following subjects.HistoryWood Energy: From 1985 until 2008: Doing business as Global Energy, developed and sold wood energy (biomass) systems. First with selling Waterwide Gasifiers from New Zealand in 1986, and then branching off into developing and selling my own systems, including steam turbines and steam engines. Container Kiln: In the mid 1990s, developed and sold a shipping container lumber/firewood dry kiln system (Container Kiln), which was modular and portable. Section 29 Non-Conventional Fuel Credit:Also in the 1990's developed and assisted groups wanting to get tax credits for landfill gas, as well as wood gas under the Section 29 (non-conventional fuel) tax credit. As a wood energy specialist, I pointed out that wood doesn't burn, but it's actually the gas released from the wood. Many companies saved (or got refunded) millions of tax dollars.Non-conventional fuel tax creditCapstone Turbine Secondary Market:In 2001 started consulting and selling the Capstone Microturbine (micro distributed grid power generator) and currently buy and sell these turbines into the secondary market.Capstone TurbineGas to Liquids:In 2004 formed Ocean Ethanol LLC with an investor to develop my invention of converting CO2 into fuel grade ethanol, methanol, and butanol. With a short development window, we proved we could make alcohol fuel cheaper than existing fuel prices, but investor pulled out within 6 months, since he did not see an immediate return (even though it was projected to take at least 12 months to market). We were able to produce methanol and butanol from reversing a fuel cell (i.e. input was liquid CO2, water, and electricity, and output was alcohol). Catalysts were developed at PNL (Pacific Northwest Labs).Research was also done simultaneously in Italy, and a lab was able to show we could produce butanol and methanol from liquid CO2 by reversing a fuel cell.As a result I was issued two patents for my Modular Fluid Handling Device I and II in my name, and I have sole ownership of patents. It was this initial research and development into liquid CO2, that gives us the advantage in the CO2 extraction field.Modular Block PatentWaste Heat to Energy:In 2008 I started Infinity Turbine LLC to discover, promote, develop, and build waste heat to power (renewable energy) systems. For a number of years, owned and operated a fulling functioning machine shop near Seattle, Washington with a waterjet, laser, and vertical milling machine. We experimented with most forms of prime movers, including the Tesla Disc Turbine, Sterling Engine, Axial Turbine, Scroll Compressors, Scroll Expanders/Compressors, and finally settled on the Radial Outflow Turbine. We employed the services of Henry Technologies in Canada to build the heat exchangers for our Organic Rankine Cycle systems, and then paired with our turbine generator builds. The predominant challenges were pressure seals, rotational speed, and moving parts. Basically, if you have more than one moving part, the system will fail. With the interest in CO2 as the working fluid (to reduce equipment footprint by increasing efficiency and pressure to produce rotational mechanical energy), we starting experimenting with liquid CO2 and phase change. Ultimately, the Holy Grail of power production is to reduce the number of moving parts and seals to a minimum.Solid State Turbine:In our CO2 experiments, we studied the Colorado Springs notes from Nikola Tesla. I found some interesting characteristics of CO2 as it undergoes phase changes, including a tremendous production of static (DC) electricity. To that end, we started to develop a Solid State Turbine using Tribo Effect. I found that by using a hybrid polymer material, we could generate static electricity simply by pressure reduction of CO2 gas. Similar electrostatic effects were seen all the way back to the origins of steam power (coined the Armstrong Effect). The electrodynamic gas two phase system not only pertains to water-steam relations but any gaseous liquid two phase components. It can also cause explosions when using CO2 fire extinguishers, as seen in a silo explosion in Norway in 2010 and in multiple accidents when the static discharge seeded an explosion, as presented in this article. Using phase change to our advantage may be able to be the next Holy Grail of energy production. Why ? No moving parts. Plus CO2 goes supercritical at 89F or 30C, which allows utilization of low grade heat (as in the cloud server farms or even solar thermal parking lots). A Solid State Turbine scales up and down easily, and could even be used by Elon Musk for his Solar City or on Tesla cars to power the thermal management system by simply putting up black colored tubes on the roof to capture solar thermal energy. A new wave of HVAC strategy could combine low temperature solar thermal, along with ground geothermal for cooling (Organic Rankine Cycle needs both heat and cold sink). The ultimate Solid State Turbine deployment would be with a cavitation CO2 pump, for the least amount of moving parts (one). This is the system which will power us into the next few decades.Electrostatic EffectsPlasma Wing:Some of the research for Corona Discharge also led to studying plasma generated by a static field. This may be applied to aircraft wings for wing deicing (mitigation) and even some interesting methods of increase lift, which may impact applications for silent drone propellers. You will notice static mitigation on wings by the use of static whips (on the tailing edge of most aircraft wings).Botanical Extraction Systems:Starting in 2015, I started Infinity Supercritical, which uses the CO2 phase change process to extract oil from plants. It turns out that the same ORC system, can be used for plant oil extraction. It was in the past five years with this process development that we perfected CO2 phase change, and actually discovered the corona discharge for ourselves (shop workers were getting shocked while venting CO2). The CO2 phase change systems can also be used to sterilize PPE, and recycling precious metals from lithum ion batteries (LIB), and some have even proposed it is more valuable than Gold Mining.Infinity Supercritical CO2 TechnologiesHydrodynamic Cavitation Processing Systems:Concurrent with the Modular Blocks and Extraction Systems, I developed a Spinning Disc Reactor for process intensification. Termed the Sonic Extractor, this device uses spinning discs to hydrodynamically cavitate water. It turns out that you can also cavitation CO2 (quite easily) which allows us to use a spinning disc to phase change CO2 from a liquid to gas, and act as a pump. This methodology is perfect for Silver Nanoparticle production, and other continuous push-button manufacturing.Induction Magnetics:In my quest for better and faster processing of botanicals, I have also developed a induction (touchless) mixing system based on a micro version of the Bitter Plate Magnet. This fun little project allows DIY at-home making and formulation of cosmetics and skin creams.Counter-Rotating Turbine with One Moving Part:Years ago I designed and 3-D printed (in metal) a one part assembly which acted as both a turbine, and a turbo-pump. This counter-rotating design takes the best of what 3-D printing has to offer, while simultaneously mitigating the inherencies of modern turbine design (seal, temperature, and moving part issues). While this design was primarily for energy production in the ORC process, it could easily be ported to a turbofan design for drones. Imagine a drone, which was sucked up, instead of the traditional method of thrust-down. Along with thrust-down also comes lots of noise. In this case using a Counter-Rotating Turbine, a vortex would suck up the drone, and all noise would be projected into the sky. An added benefit (other than low noise) would be a very low heat signature, since compressed and expelled exhaust are mixed together.Phase Change Battery:Using CO2 (which is a energy dense working fluid) leveraging the phase change would essentially make pressure the electrolyte. This battery concept can accept multiple charging inputs including heat, electricity, and friction to store energy.CO2 Gas Turbine:With a cavitating disc compressor, CO2 (instead of air) would make a very interesting high altitude gas turbine, which leverages the cold temperatures of high altitude for condensing, while making a closed-loop, energy efficient power unit, which could power electric turbofans for commercial aircraft.Gas Leverage Turbine:Extending CO2 Gas Turbine concept, a industrial version could be used in harmony with CO2 and its sonichemistry reactions to make industrial goods, such as gas-to-liquids, chemicals, and other industrial raw goods.FileMaker PDF Algorithm Research and Development:Infinity has been using Filemaker since 1993, and is now diving into the analyst world of deciphering data. First project is GME (Gamestock). The algorithm is based on finding stocks that are being sold short, in combination with hedge fund or other fund shorts. These lists are publicly available in Europe, but a bit harder to find in the USA. The goal is to identify good candidates which may go up in price, as a result of social media (Redditt) and industrial grade short sellers.

|