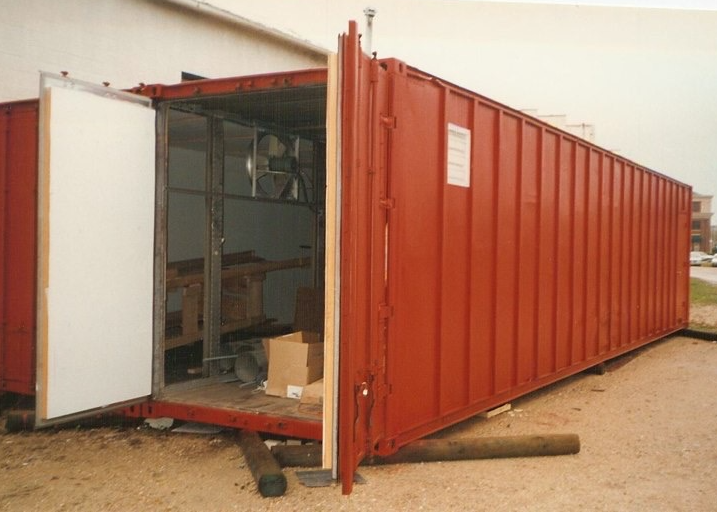

ElectraTherm 125 kWe System with Hurst Boiler Packaged in a 40 Foot Shipping Container Ready to Deploy

A used turnkey waste-heat-to-power system is now available, fully integrated inside a 40-foot shipping container and in near-new condition with minimal runtime. of 39 hours. This self-contained unit pairs a Hurst Series 250 boiler with an ElectraTherm Power Organic Rankine Cycle 125 kWe 480 V 3 phase 60 hz generator, designed to efficiently convert low-grade heat into grid-ready electricity. Factory-tested, fully certified, and equipped with advanced PLC controls, rapid startup, and built-in safety systems, this containerized power solution offers a compact, transportable, and ready-to-deploy energy asset.Perfect for BioChar production, industrial waste heat, biomass, and can be converted for solar thermal or concentrated solar. Produces 1,095,000 kWh annually at continuous full load.Revenue from 125 kWe System (24 hours x 365 days per year x 125 kWh = 1,095,000 kWh per year):at $.20 per kWh = $219,000 USD per yearat $.40 per kWh = $438,000 USD per yearat $.80 per kWh = $657,000 USD per yearThe Hurst Boiler is set up ready for your waste heat, or you can exit your sawdust/biomass burner directly into the boiler. The boiler can also use a LPG or NG gas burner. The system is also set up for using biochar waste heat to make power.