PDF Publication Title:

Text from PDF Page: 003

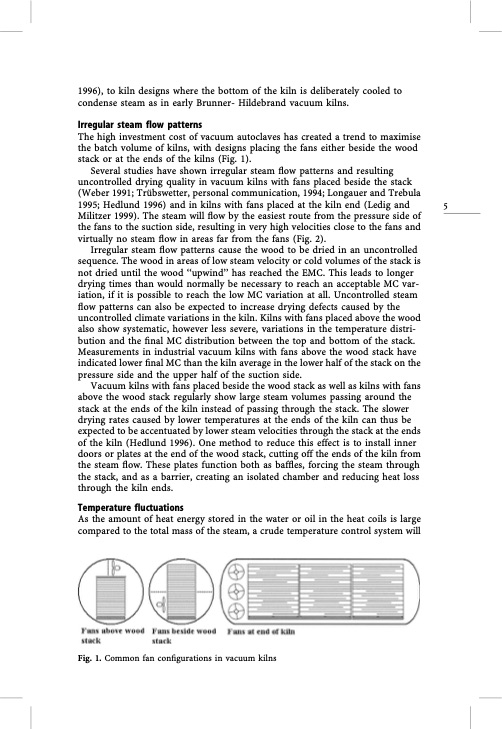

1996), to kiln designs where the bottom of the kiln is deliberately cooled to condense steam as in early Brunner- Hildebrand vacuum kilns. Irregular steam flow patterns The high investment cost of vacuum autoclaves has created a trend to maximise the batch volume of kilns, with designs placing the fans either beside the wood stack or at the ends of the kilns (Fig. 1). Several studies have shown irregular steam flow patterns and resulting uncontrolled drying quality in vacuum kilns with fans placed beside the stack (Weber 1991; Tru ̈bswetter, personal communication, 1994; Longauer and Trebula 1995; Hedlund 1996) and in kilns with fans placed at the kiln end (Ledig and 5 Militzer 1999). The steam will flow by the easiest route from the pressure side of the fans to the suction side, resulting in very high velocities close to the fans and virtually no steam flow in areas far from the fans (Fig. 2). Irregular steam flow patterns cause the wood to be dried in an uncontrolled sequence. The wood in areas of low steam velocity or cold volumes of the stack is not dried until the wood ‘‘upwind’’ has reached the EMC. This leads to longer drying times than would normally be necessary to reach an acceptable MC var- iation, if it is possible to reach the low MC variation at all. Uncontrolled steam flow patterns can also be expected to increase drying defects caused by the uncontrolled climate variations in the kiln. Kilns with fans placed above the wood also show systematic, however less severe, variations in the temperature distri- bution and the final MC distribution between the top and bottom of the stack. Measurements in industrial vacuum kilns with fans above the wood stack have indicated lower final MC than the kiln average in the lower half of the stack on the pressure side and the upper half of the suction side. Vacuum kilns with fans placed beside the wood stack as well as kilns with fans above the wood stack regularly show large steam volumes passing around the stack at the ends of the kiln instead of passing through the stack. The slower drying rates caused by lower temperatures at the ends of the kiln can thus be expected to be accentuated by lower steam velocities through the stack at the ends of the kiln (Hedlund 1996). One method to reduce this effect is to install inner doors or plates at the end of the wood stack, cutting off the ends of the kiln from the steam flow. These plates function both as baffles, forcing the steam through the stack, and as a barrier, creating an isolated chamber and reducing heat loss through the kiln ends. Temperature fluctuations As the amount of heat energy stored in the water or oil in the heat coils is large compared to the total mass of the steam, a crude temperature control system will Fig. 1. Common fan configurations in vacuum kilnsPDF Image | Tech Table: Vacuum bagging supplies

PDF Search Title:

Tech Table: Vacuum bagging suppliesOriginal File Name Searched:

vacuum-dryer-heat.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |