PDF Publication Title:

Text from PDF Page: 004

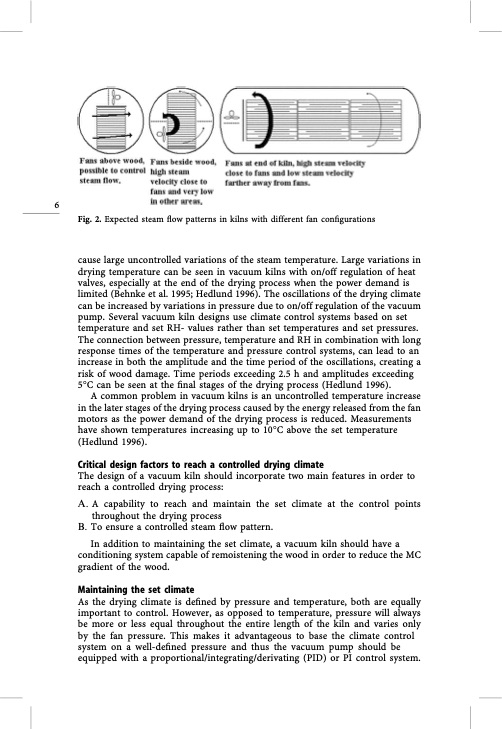

6 Fig. 2. Expected steam flow patterns in kilns with different fan configurations cause large uncontrolled variations of the steam temperature. Large variations in drying temperature can be seen in vacuum kilns with on/off regulation of heat valves, especially at the end of the drying process when the power demand is limited (Behnke et al. 1995; Hedlund 1996). The oscillations of the drying climate can be increased by variations in pressure due to on/off regulation of the vacuum pump. Several vacuum kiln designs use climate control systems based on set temperature and set RH- values rather than set temperatures and set pressures. The connection between pressure, temperature and RH in combination with long response times of the temperature and pressure control systems, can lead to an increase in both the amplitude and the time period of the oscillations, creating a risk of wood damage. Time periods exceeding 2.5 h and amplitudes exceeding 5°C can be seen at the final stages of the drying process (Hedlund 1996). A common problem in vacuum kilns is an uncontrolled temperature increase in the later stages of the drying process caused by the energy released from the fan motors as the power demand of the drying process is reduced. Measurements have shown temperatures increasing up to 10°C above the set temperature (Hedlund 1996). Critical design factors to reach a controlled drying climate The design of a vacuum kiln should incorporate two main features in order to reach a controlled drying process: A. A capability to reach and maintain the set climate at the control points throughout the drying process B. To ensure a controlled steam flow pattern. In addition to maintaining the set climate, a vacuum kiln should have a conditioning system capable of remoistening the wood in order to reduce the MC gradient of the wood. Maintaining the set climate As the drying climate is defined by pressure and temperature, both are equally important to control. However, as opposed to temperature, pressure will always be more or less equal throughout the entire length of the kiln and varies only by the fan pressure. This makes it advantageous to base the climate control system on a well-defined pressure and thus the vacuum pump should be equipped with a proportional/integrating/derivating (PID) or PI control system.PDF Image | Tech Table: Vacuum bagging supplies

PDF Search Title:

Tech Table: Vacuum bagging suppliesOriginal File Name Searched:

vacuum-dryer-heat.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |