PDF Publication Title:

Text from PDF Page: 002

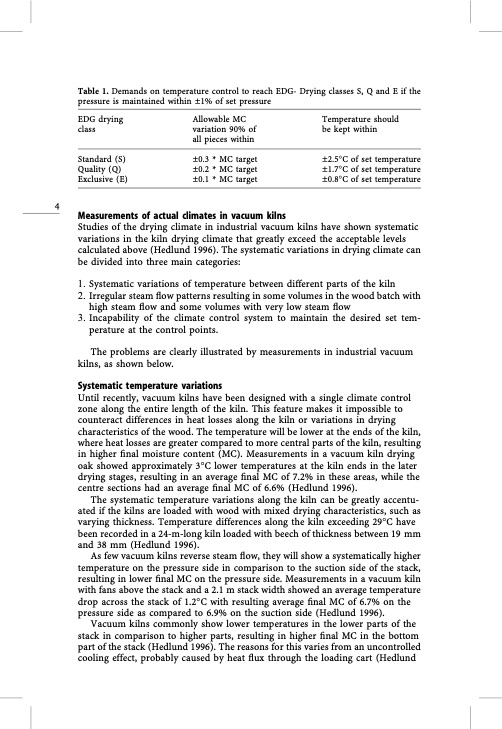

Table 1. Demands on temperature control to reach EDG- Drying classes S, Q and E if the pressure is maintained within ±1% of set pressure EDG drying class Standard (S) Quality (Q) Exclusive (E) Allowable MC variation 90% of all pieces within ±0.3 * MC target ±0.2 * MC target ±0.1 * MC target Temperature should be kept within ±2.5°C of set temperature ±1.7°C of set temperature ±0.8°C of set temperature 4 Measurements of actual climates in vacuum kilns Studies of the drying climate in industrial vacuum kilns have shown systematic variations in the kiln drying climate that greatly exceed the acceptable levels calculated above (Hedlund 1996). The systematic variations in drying climate can be divided into three main categories: 1. Systematic variations of temperature between different parts of the kiln 2. Irregular steam flow patterns resulting in some volumes in the wood batch with high steam flow and some volumes with very low steam flow 3. Incapability of the climate control system to maintain the desired set tem- perature at the control points. The problems are clearly illustrated by measurements in industrial vacuum kilns, as shown below. Systematic temperature variations Until recently, vacuum kilns have been designed with a single climate control zone along the entire length of the kiln. This feature makes it impossible to counteract differences in heat losses along the kiln or variations in drying characteristics of the wood. The temperature will be lower at the ends of the kiln, where heat losses are greater compared to more central parts of the kiln, resulting in higher final moisture content (MC). Measurements in a vacuum kiln drying oak showed approximately 3°C lower temperatures at the kiln ends in the later drying stages, resulting in an average final MC of 7.2% in these areas, while the centre sections had an average final MC of 6.6% (Hedlund 1996). The systematic temperature variations along the kiln can be greatly accentu- ated if the kilns are loaded with wood with mixed drying characteristics, such as varying thickness. Temperature differences along the kiln exceeding 29°C have been recorded in a 24-m-long kiln loaded with beech of thickness between 19 mm and 38 mm (Hedlund 1996). As few vacuum kilns reverse steam flow, they will show a systematically higher temperature on the pressure side in comparison to the suction side of the stack, resulting in lower final MC on the pressure side. Measurements in a vacuum kiln with fans above the stack and a 2.1 m stack width showed an average temperature drop across the stack of 1.2°C with resulting average final MC of 6.7% on the pressure side as compared to 6.9% on the suction side (Hedlund 1996). Vacuum kilns commonly show lower temperatures in the lower parts of the stack in comparison to higher parts, resulting in higher final MC in the bottom part of the stack (Hedlund 1996). The reasons for this varies from an uncontrolled cooling effect, probably caused by heat flux through the loading cart (HedlundPDF Image | Tech Table: Vacuum bagging supplies

PDF Search Title:

Tech Table: Vacuum bagging suppliesOriginal File Name Searched:

vacuum-dryer-heat.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |