PDF Publication Title:

Text from PDF Page: 003

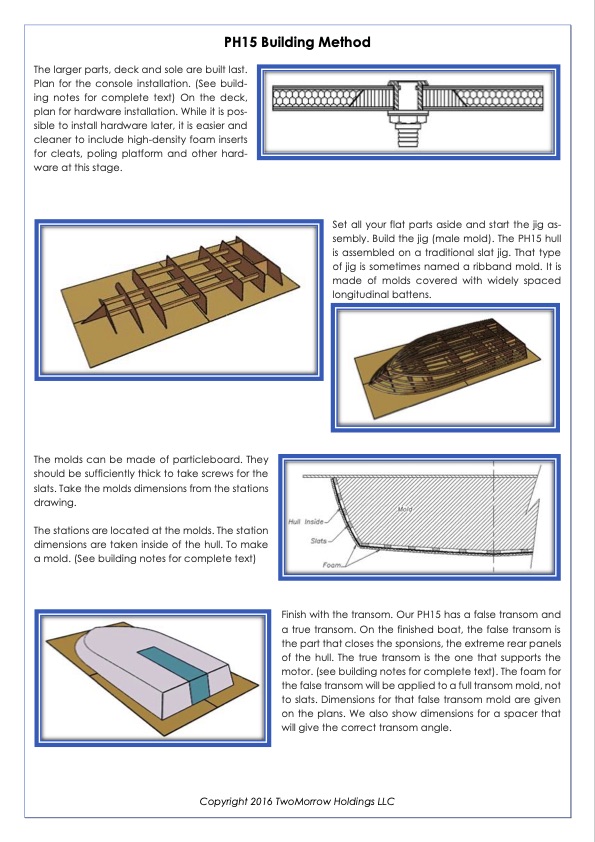

PH15 Building Method The larger parts, deck and sole are built last. Plan for the console installation. (See build- ing notes for complete text) On the deck, plan for hardware installation. While it is pos- sible to install hardware later, it is easier and cleaner to include high-density foam inserts for cleats, poling platform and other hard- ware at this stage. Set all your flat parts aside and start the jig as- sembly. Build the jig (male mold). The PH15 hull is assembled on a traditional slat jig. That type of jig is sometimes named a ribband mold. It is made of molds covered with widely spaced longitudinal battens. The molds can be made of particleboard. They should be sufficiently thick to take screws for the slats. Take the molds dimensions from the stations drawing. The stations are located at the molds. The station dimensions are taken inside of the hull. To make a mold. (See building notes for complete text) Finish with the transom. Our PH15 has a false transom and a true transom. On the finished boat, the false transom is the part that closes the sponsions, the extreme rear panels of the hull. The true transom is the one that supports the motor. (see building notes for complete text). The foam for the false transom will be applied to a full transom mold, not to slats. Dimensions for that false transom mold are given on the plans. We also show dimensions for a spacer that will give the correct transom angle. Copyright 2016 TwoMorrow Holdings LLCPDF Image | PH15 Building Method Vacuum Bagging

PDF Search Title:

PH15 Building Method Vacuum BaggingOriginal File Name Searched:

ph15-building-method.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |