PDF Publication Title:

Text from PDF Page: 002

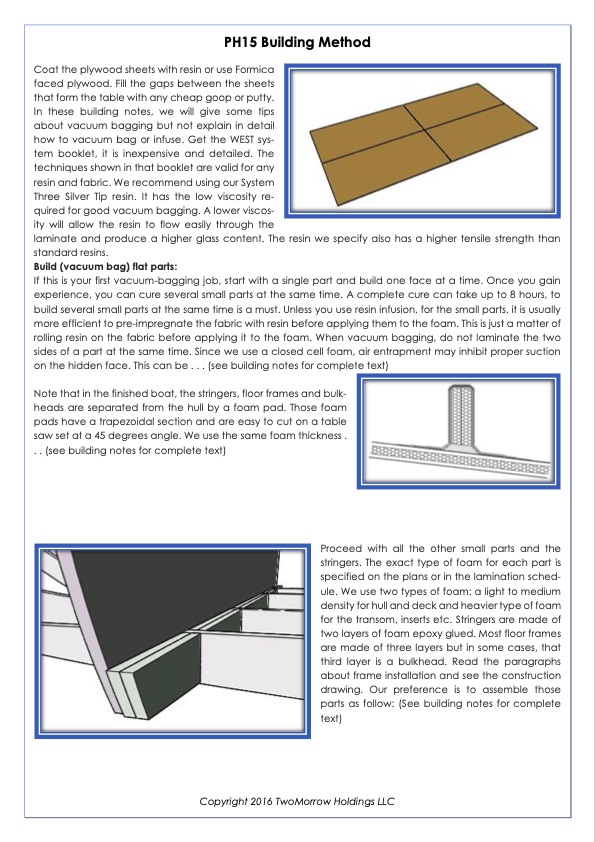

PH15 Building Method Coat the plywood sheets with resin or use Formica faced plywood. Fill the gaps between the sheets that form the table with any cheap goop or putty. In these building notes, we will give some tips about vacuum bagging but not explain in detail how to vacuum bag or infuse. Get the WEST sys- tem booklet, it is inexpensive and detailed. The techniques shown in that booklet are valid for any resin and fabric. We recommend using our System Three Silver Tip resin. It has the low viscosity re- quired for good vacuum bagging. A lower viscos- ity will allow the resin to flow easily through the laminate and produce a higher glass content. The resin we specify also has a higher tensile strength than standard resins. Build (vacuum bag) flat parts: If this is your first vacuum-bagging job, start with a single part and build one face at a time. Once you gain experience, you can cure several small parts at the same time. A complete cure can take up to 8 hours, to build several small parts at the same time is a must. Unless you use resin infusion, for the small parts, it is usually more efficient to pre-impregnate the fabric with resin before applying them to the foam. This is just a matter of rolling resin on the fabric before applying it to the foam. When vacuum bagging, do not laminate the two sides of a part at the same time. Since we use a closed cell foam, air entrapment may inhibit proper suction on the hidden face. This can be . . . (see building notes for complete text) Note that in the finished boat, the stringers, floor frames and bulk- heads are separated from the hull by a foam pad. Those foam pads have a trapezoidal section and are easy to cut on a table saw set at a 45 degrees angle. We use the same foam thickness . . . (see building notes for complete text) Proceed with all the other small parts and the stringers. The exact type of foam for each part is specified on the plans or in the lamination sched- ule. We use two types of foam: a light to medium density for hull and deck and heavier type of foam for the transom, inserts etc. Stringers are made of two layers of foam epoxy glued. Most floor frames are made of three layers but in some cases, that third layer is a bulkhead. Read the paragraphs about frame installation and see the construction drawing. Our preference is to assemble those parts as follow: (See building notes for complete text) Copyright 2016 TwoMorrow Holdings LLCPDF Image | PH15 Building Method Vacuum Bagging

PDF Search Title:

PH15 Building Method Vacuum BaggingOriginal File Name Searched:

ph15-building-method.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |