PDF Publication Title:

Text from PDF Page: 038

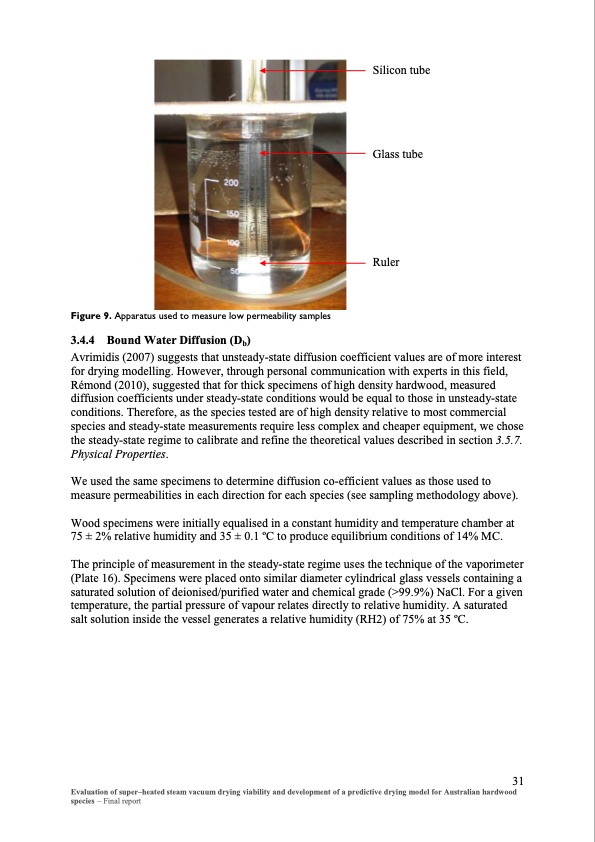

Silicon tube Glass tube Ruler Figure 9. Apparatus used to measure low permeability samples 3.4.4 Bound Water Diffusion (Db) Avrimidis (2007) suggests that unsteady-state diffusion coefficient values are of more interest for drying modelling. However, through personal communication with experts in this field, Rémond (2010), suggested that for thick specimens of high density hardwood, measured diffusion coefficients under steady-state conditions would be equal to those in unsteady-state conditions. Therefore, as the species tested are of high density relative to most commercial species and steady-state measurements require less complex and cheaper equipment, we chose the steady-state regime to calibrate and refine the theoretical values described in section 3.5.7. Physical Properties. We used the same specimens to determine diffusion co-efficient values as those used to measure permeabilities in each direction for each species (see sampling methodology above). Wood specimens were initially equalised in a constant humidity and temperature chamber at 75 ± 2% relative humidity and 35 ± 0.1 oC to produce equilibrium conditions of 14% MC. The principle of measurement in the steady-state regime uses the technique of the vaporimeter (Plate 16). Specimens were placed onto similar diameter cylindrical glass vessels containing a saturated solution of deionised/purified water and chemical grade (>99.9%) NaCl. For a given temperature, the partial pressure of vapour relates directly to relative humidity. A saturated salt solution inside the vessel generates a relative humidity (RH2) of 75% at 35 oC. 31 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |