PDF Publication Title:

Text from PDF Page: 037

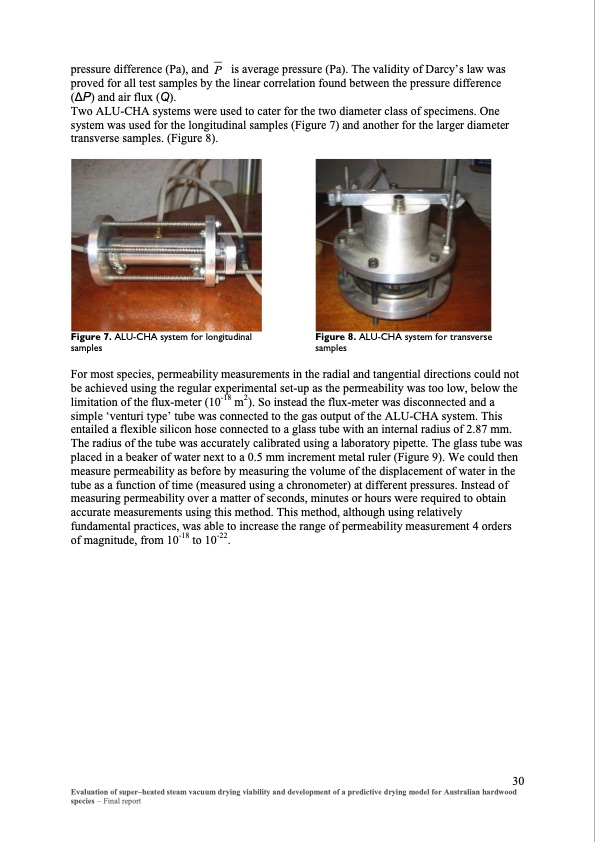

pressure difference (Pa), and P is average pressure (Pa). The validity of Darcy’s law was proved for all test samples by the linear correlation found between the pressure difference (ΔP) and air flux (Q). Two ALU-CHA systems were used to cater for the two diameter class of specimens. One system was used for the longitudinal samples (Figure 7) and another for the larger diameter transverse samples. (Figure 8). Figure 7. ALU-CHA system for longitudinal Figure 8. ALU-CHA system for transverse samples samples For most species, permeability measurements in the radial and tangential directions could not be achieved using the regular experimental set-up as the permeability was too low, below the limitation of the flux-meter (10-18 m2). So instead the flux-meter was disconnected and a simple ‘venturi type’ tube was connected to the gas output of the ALU-CHA system. This entailed a flexible silicon hose connected to a glass tube with an internal radius of 2.87 mm. The radius of the tube was accurately calibrated using a laboratory pipette. The glass tube was placed in a beaker of water next to a 0.5 mm increment metal ruler (Figure 9). We could then measure permeability as before by measuring the volume of the displacement of water in the tube as a function of time (measured using a chronometer) at different pressures. Instead of measuring permeability over a matter of seconds, minutes or hours were required to obtain accurate measurements using this method. This method, although using relatively fundamental practices, was able to increase the range of permeability measurement 4 orders of magnitude, from 10-18 to 10-22. 30 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |