PDF Publication Title:

Text from PDF Page: 039

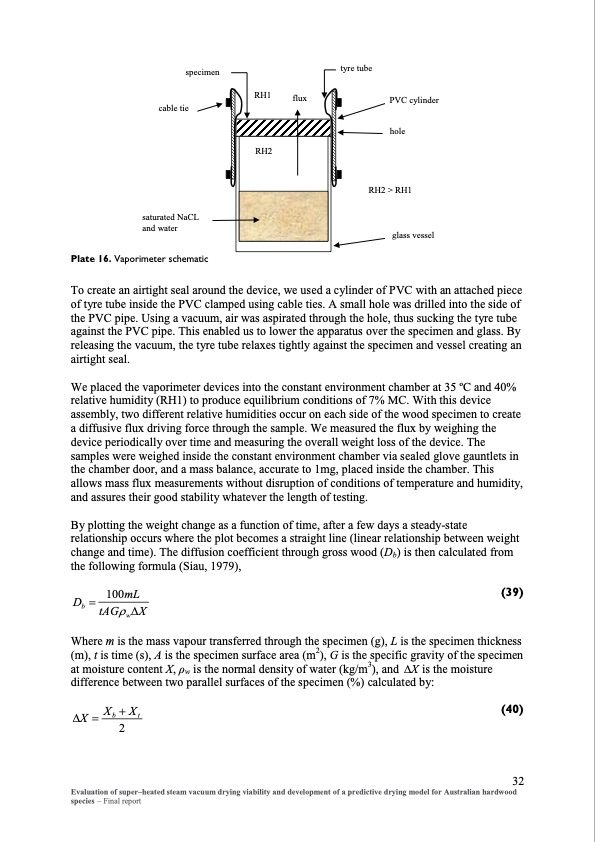

specimen RH1 cable tie saturated NaCL and water Plate 16. Vaporimeter schematic tyre tube flux PVC cylinder hole RH2 RH2 > RH1 glass vessel To create an airtight seal around the device, we used a cylinder of PVC with an attached piece of tyre tube inside the PVC clamped using cable ties. A small hole was drilled into the side of the PVC pipe. Using a vacuum, air was aspirated through the hole, thus sucking the tyre tube against the PVC pipe. This enabled us to lower the apparatus over the specimen and glass. By releasing the vacuum, the tyre tube relaxes tightly against the specimen and vessel creating an airtight seal. We placed the vaporimeter devices into the constant environment chamber at 35 oC and 40% relative humidity (RH1) to produce equilibrium conditions of 7% MC. With this device assembly, two different relative humidities occur on each side of the wood specimen to create a diffusive flux driving force through the sample. We measured the flux by weighing the device periodically over time and measuring the overall weight loss of the device. The samples were weighed inside the constant environment chamber via sealed glove gauntlets in the chamber door, and a mass balance, accurate to 1mg, placed inside the chamber. This allows mass flux measurements without disruption of conditions of temperature and humidity, and assures their good stability whatever the length of testing. By plotting the weight change as a function of time, after a few days a steady-state relationship occurs where the plot becomes a straight line (linear relationship between weight change and time). The diffusion coefficient through gross wood (Db) is then calculated from the following formula (Siau, 1979), Db = 100mL tAGρ w ∆X (39) Where m is the mass vapour transferred through the specimen (g), L is the specimen thickness (m), t is time (s), A is the specimen surface area (m2), G is the specific gravity of the specimen at moisture content X, ρw is the normal density of water (kg/m3), and ∆X is the moisture difference between two parallel surfaces of the specimen (%) calculated by: ∆X = Xb + Xt 2 (40) 32 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |