PDF Publication Title:

Text from PDF Page: 029

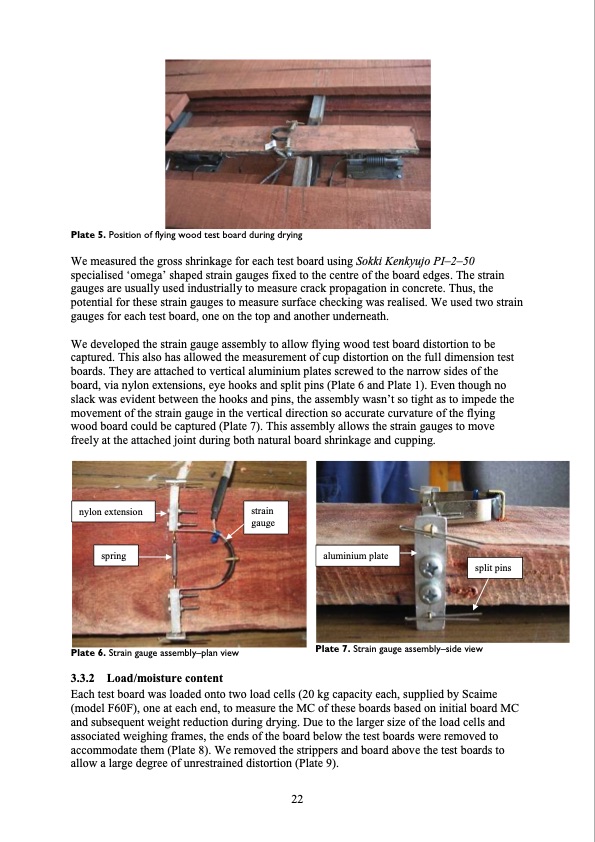

Plate 5. Position of flying wood test board during drying We measured the gross shrinkage for each test board using Sokki Kenkyujo PI–2–50 specialised ‘omega’ shaped strain gauges fixed to the centre of the board edges. The strain gauges are usually used industrially to measure crack propagation in concrete. Thus, the potential for these strain gauges to measure surface checking was realised. We used two strain gauges for each test board, one on the top and another underneath. We developed the strain gauge assembly to allow flying wood test board distortion to be captured. This also has allowed the measurement of cup distortion on the full dimension test boards. They are attached to vertical aluminium plates screwed to the narrow sides of the board, via nylon extensions, eye hooks and split pins (Plate 6 and Plate 1). Even though no slack was evident between the hooks and pins, the assembly wasn’t so tight as to impede the movement of the strain gauge in the vertical direction so accurate curvature of the flying wood board could be captured (Plate 7). This assembly allows the strain gauges to move freely at the attached joint during both natural board shrinkage and cupping. nylon extension spring Plate 6. Strain gauge assembly–plan view 3.3.2 Load/moisture content aluminium plate split pins strain gauge Each test board was loaded onto two load cells (20 kg capacity each, supplied by Scaime (model F60F), one at each end, to measure the MC of these boards based on initial board MC and subsequent weight reduction during drying. Due to the larger size of the load cells and associated weighing frames, the ends of the board below the test boards were removed to accommodate them (Plate 8). We removed the strippers and board above the test boards to allow a large degree of unrestrained distortion (Plate 9). 22 Plate 7. Strain gauge assembly–side viewPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |