PDF Publication Title:

Text from PDF Page: 028

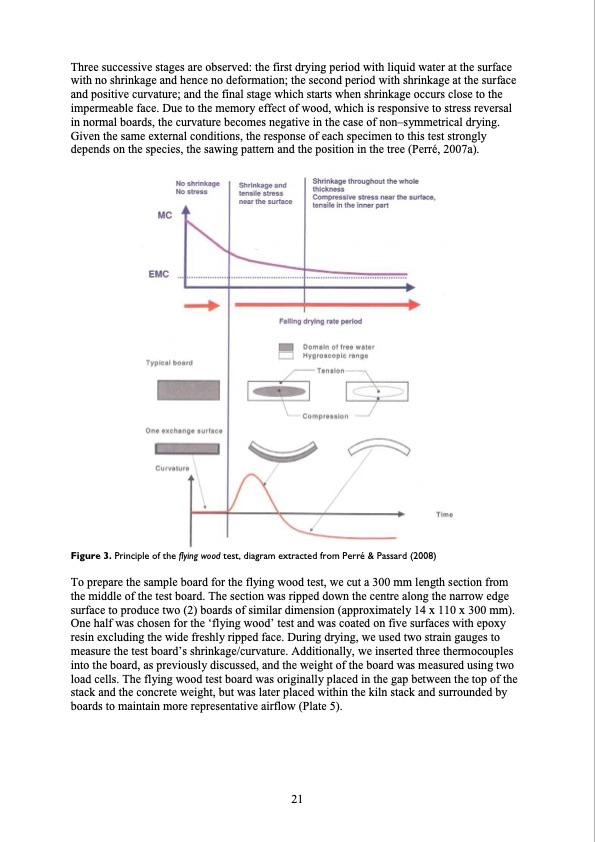

Three successive stages are observed: the first drying period with liquid water at the surface with no shrinkage and hence no deformation; the second period with shrinkage at the surface and positive curvature; and the final stage which starts when shrinkage occurs close to the impermeable face. Due to the memory effect of wood, which is responsive to stress reversal in normal boards, the curvature becomes negative in the case of non–symmetrical drying. Given the same external conditions, the response of each specimen to this test strongly depends on the species, the sawing pattern and the position in the tree (Perré, 2007a). Figure 3. Principle of the flying wood test, diagram extracted from Perré & Passard (2008) To prepare the sample board for the flying wood test, we cut a 300 mm length section from the middle of the test board. The section was ripped down the centre along the narrow edge surface to produce two (2) boards of similar dimension (approximately 14 x 110 x 300 mm). One half was chosen for the ‘flying wood’ test and was coated on five surfaces with epoxy resin excluding the wide freshly ripped face. During drying, we used two strain gauges to measure the test board’s shrinkage/curvature. Additionally, we inserted three thermocouples into the board, as previously discussed, and the weight of the board was measured using two load cells. The flying wood test board was originally placed in the gap between the top of the stack and the concrete weight, but was later placed within the kiln stack and surrounded by boards to maintain more representative airflow (Plate 5). 21PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |