PDF Publication Title:

Text from PDF Page: 003

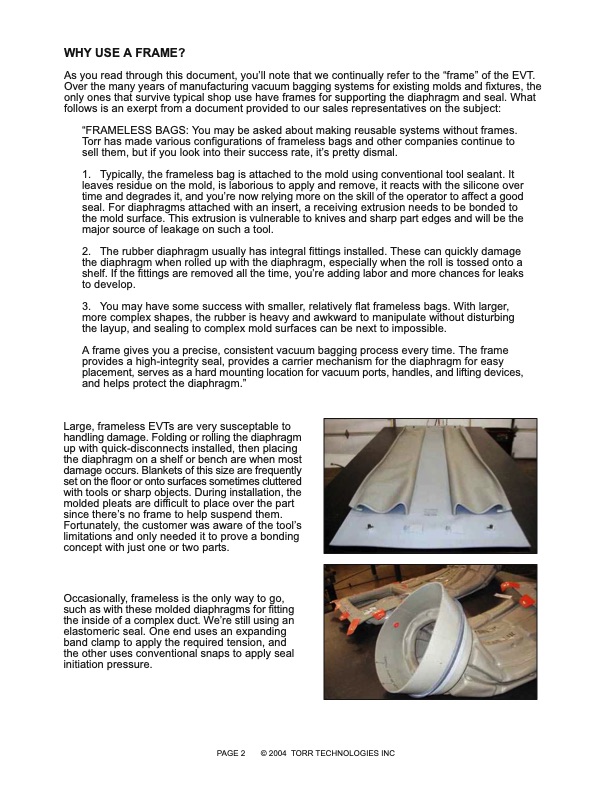

WHY USE A FRAME? As you read through this document, you’ll note that we continually refer to the “frame” of the EVT. Over the many years of manufacturing vacuum bagging systems for existing molds and fixtures, the only ones that survive typical shop use have frames for supporting the diaphragm and seal. What follows is an exerpt from a document provided to our sales representatives on the subject: “FRAMELESS BAGS: You may be asked about making reusable systems without frames. Torr has made various configurations of frameless bags and other companies continue to sell them, but if you look into their success rate, it’s pretty dismal. 1. Typically, the frameless bag is attached to the mold using conventional tool sealant. It leaves residue on the mold, is laborious to apply and remove, it reacts with the silicone over time and degrades it, and you’re now relying more on the skill of the operator to affect a good seal. For diaphragms attached with an insert, a receiving extrusion needs to be bonded to the mold surface. This extrusion is vulnerable to knives and sharp part edges and will be the major source of leakage on such a tool. 2. The rubber diaphragm usually has integral fittings installed. These can quickly damage the diaphragm when rolled up with the diaphragm, especially when the roll is tossed onto a shelf. If the fittings are removed all the time, you’re adding labor and more chances for leaks to develop. 3. You may have some success with smaller, relatively flat frameless bags. With larger, more complex shapes, the rubber is heavy and awkward to manipulate without disturbing the layup, and sealing to complex mold surfaces can be next to impossible. A frame gives you a precise, consistent vacuum bagging process every time. The frame provides a high-integrity seal, provides a carrier mechanism for the diaphragm for easy placement, serves as a hard mounting location for vacuum ports, handles, and lifting devices, and helps protect the diaphragm.” Large, frameless EVTs are very susceptable to handling damage. Folding or rolling the diaphragm up with quick-disconnects installed, then placing the diaphragm on a shelf or bench are when most damage occurs. Blankets of this size are frequently set on the floor or onto surfaces sometimes cluttered with tools or sharp objects. During installation, the molded pleats are difficult to place over the part since there’s no frame to help suspend them. Fortunately, the customer was aware of the tool’s limitations and only needed it to prove a bonding concept with just one or two parts. Occasionally, frameless is the only way to go, such as with these molded diaphragms for fitting the inside of a complex duct. We’re still using an elastomeric seal. One end uses an expanding band clamp to apply the required tension, and the other uses conventional snaps to apply seal initiation pressure. PAGE 2 © 2004 TORR TECHNOLOGIES INCPDF Image | DESIGNING MOLDS AND FIXTURES Vacuum Bagging

PDF Search Title:

DESIGNING MOLDS AND FIXTURES Vacuum BaggingOriginal File Name Searched:

TorrMDG.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |