PDF Publication Title:

Text from PDF Page: 004

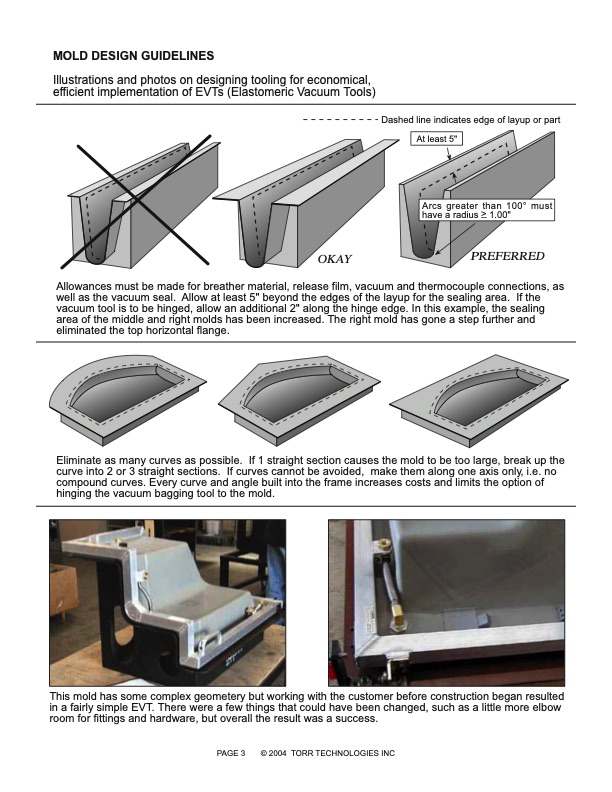

MOLD DESIGN GUIDELINES Illustrations and photos on designing tooling for economical, efficient implementation of EVTs (Elastomeric Vacuum Tools) Dashed line indicates edge of layup or part Allowances must be made for breather material, release film, vacuum and thermocouple connections, as well as the vacuum seal. Allow at least 5" beyond the edges of the layup for the sealing area. If the vacuum tool is to be hinged, allow an additional 2" along the hinge edge. In this example, the sealing area of the middle and right molds has been increased. The right mold has gone a step further and eliminated the top horizontal flange. OKAY At least 5" Arcs greater than 100° must _ have a radius > 1.00" PREFERRED Eliminate as many curves as possible. If 1 straight section causes the mold to be too large, break up the curve into 2 or 3 straight sections. If curves cannot be avoided, make them along one axis only, i.e. no compound curves. Every curve and angle built into the frame increases costs and limits the option of hinging the vacuum bagging tool to the mold. This mold has some complex geometery but working with the customer before construction began resulted in a fairly simple EVT. There were a few things that could have been changed, such as a little more elbow room for fittings and hardware, but overall the result was a success. PAGE 3 © 2004 TORR TECHNOLOGIES INCPDF Image | DESIGNING MOLDS AND FIXTURES Vacuum Bagging

PDF Search Title:

DESIGNING MOLDS AND FIXTURES Vacuum BaggingOriginal File Name Searched:

TorrMDG.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |