PDF Publication Title:

Text from PDF Page: 349

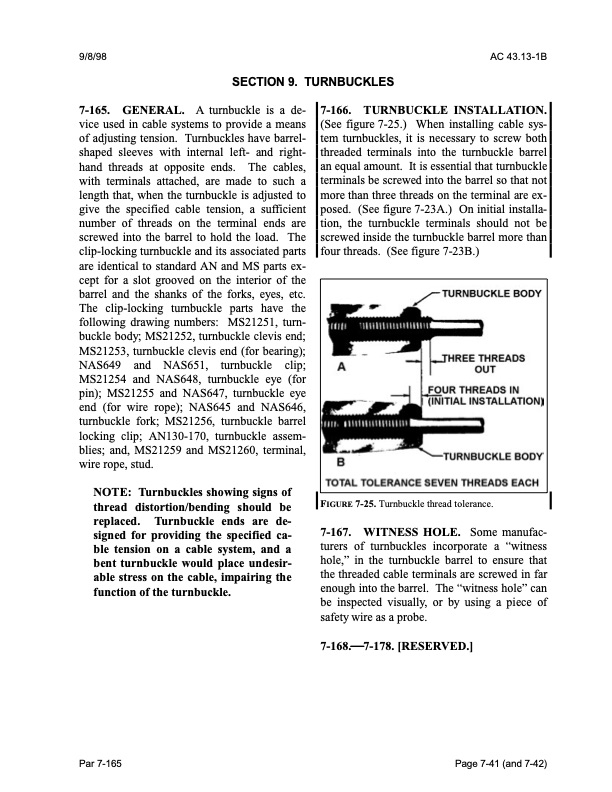

9/8/98 AC 43.13-1B 7-165. GENERAL. A turnbuckle is a de- vice used in cable systems to provide a means of adjusting tension. Turnbuckles have barrel- shaped sleeves with internal left- and right- hand threads at opposite ends. The cables, with terminals attached, are made to such a length that, when the turnbuckle is adjusted to give the specified cable tension, a sufficient number of threads on the terminal ends are screwed into the barrel to hold the load. The clip-locking turnbuckle and its associated parts are identical to standard AN and MS parts ex- cept for a slot grooved on the interior of the barrel and the shanks of the forks, eyes, etc. The clip-locking turnbuckle parts have the following drawing numbers: MS21251, turn- buckle body; MS21252, turnbuckle clevis end; MS21253, turnbuckle clevis end (for bearing); NAS649 and NAS651, turnbuckle clip; MS21254 and NAS648, turnbuckle eye (for pin); MS21255 and NAS647, turnbuckle eye end (for wire rope); NAS645 and NAS646, turnbuckle fork; MS21256, turnbuckle barrel locking clip; AN130-170, turnbuckle assem- blies; and, MS21259 and MS21260, terminal, wire rope, stud. NOTE: Turnbuckles showing signs of thread distortion/bending should be replaced. Turnbuckle ends are de- signed for providing the specified ca- ble tension on a cable system, and a bent turnbuckle would place undesir- able stress on the cable, impairing the function of the turnbuckle. 7-166. TURNBUCKLE INSTALLATION. (See figure 7-25.) When installing cable sys- tem turnbuckles, it is necessary to screw both threaded terminals into the turnbuckle barrel an equal amount. It is essential that turnbuckle terminals be screwed into the barrel so that not more than three threads on the terminal are ex- posed. (See figure 7-23A.) On initial installa- tion, the turnbuckle terminals should not be screwed inside the turnbuckle barrel more than four threads. (See figure 7-23B.) FIGURE 7-25. Turnbuckle thread tolerance. 7-167. WITNESS HOLE. Some manufac- turers of turnbuckles incorporate a “witness hole,” in the turnbuckle barrel to ensure that the threaded cable terminals are screwed in far enough into the barrel. The “witness hole” can be inspected visually, or by using a piece of safety wire as a probe. 7-168.7-178. [RESERVED.] SECTION 9. TURNBUCKLES Par 7-165 Page 7-41 (and 7-42)PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |