PDF Publication Title:

Text from PDF Page: 348

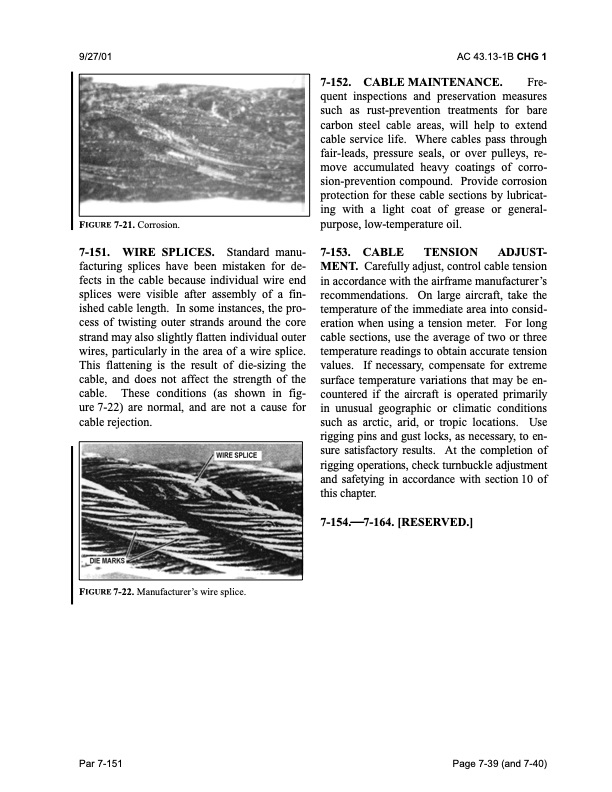

9/27/01 AC 43.13-1B CHG 1 FIGURE 7-21. Corrosion. 7-151. WIRE SPLICES. Standard manu facturing splices have been mistaken for de fects in the cable because individual wire end splices were visible after assembly of a fin ished cable length. In some instances, the pro cess of twisting outer strands around the core strand may also slightly flatten individual outer wires, particularly in the area of a wire splice. This flattening is the result of die-sizing the cable, and does not affect the strength of the cable. These conditions (as shown in fig ure 7-22) are normal, and are not a cause for cable rejection. FIGURE 7-22. Manufacturer’s wire splice. 7-152. CABLE MAINTENANCE. Fre quent inspections and preservation measures such as rust-prevention treatments for bare carbon steel cable areas, will help to extend cable service life. Where cables pass through fair-leads, pressure seals, or over pulleys, re move accumulated heavy coatings of corro sion-prevention compound. Provide corrosion protection for these cable sections by lubricat ing with a light coat of grease or general- purpose, low-temperature oil. 7-153. CABLE TENSION ADJUST- MENT. Carefully adjust, control cable tension in accordance with the airframe manufacturer’s recommendations. On large aircraft, take the temperature of the immediate area into consid eration when using a tension meter. For long cable sections, use the average of two or three temperature readings to obtain accurate tension values. If necessary, compensate for extreme surface temperature variations that may be en countered if the aircraft is operated primarily in unusual geographic or climatic conditions such as arctic, arid, or tropic locations. Use rigging pins and gust locks, as necessary, to en sure satisfactory results. At the completion of rigging operations, check turnbuckle adjustment and safetying in accordance with section 10 of this chapter. 7-154.7-164. [RESERVED.] Par 7-151 Page 7-39 (and 7-40)PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |