PDF Publication Title:

Text from PDF Page: 350

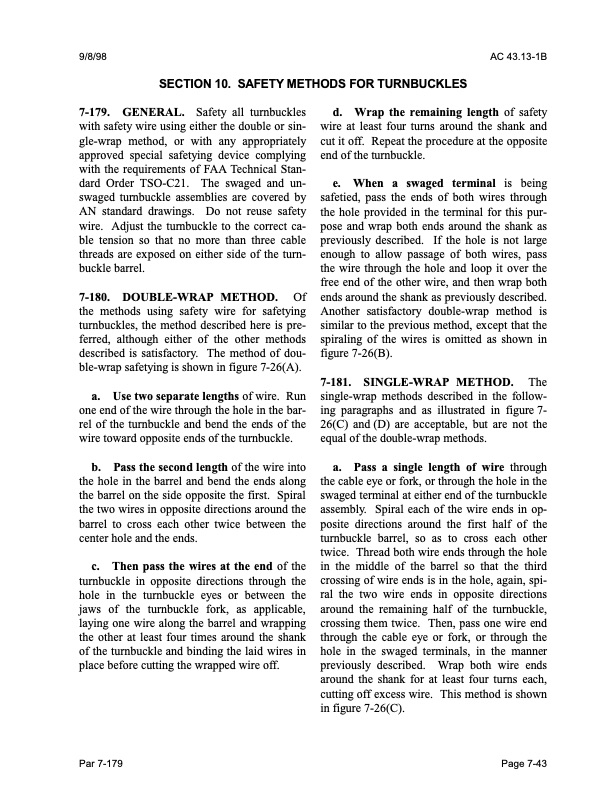

9/8/98 AC 43.13-1B SECTION 10. SAFETY METHODS FOR TURNBUCKLES 7-179. GENERAL. Safety all turnbuckles with safety wire using either the double or sin- gle-wrap method, or with any appropriately approved special safetying device complying with the requirements of FAA Technical Stan- dard Order TSO-C21. The swaged and un- swaged turnbuckle assemblies are covered by AN standard drawings. Do not reuse safety wire. Adjust the turnbuckle to the correct ca- ble tension so that no more than three cable threads are exposed on either side of the turn- buckle barrel. 7-180. DOUBLE-WRAP METHOD. Of the methods using safety wire for safetying turnbuckles, the method described here is pre- ferred, although either of the other methods described is satisfactory. The method of dou- ble-wrap safetying is shown in figure 7-26(A). a. Use two separate lengths of wire. Run one end of the wire through the hole in the bar- rel of the turnbuckle and bend the ends of the wire toward opposite ends of the turnbuckle. b. Pass the second length of the wire into the hole in the barrel and bend the ends along the barrel on the side opposite the first. Spiral the two wires in opposite directions around the barrel to cross each other twice between the center hole and the ends. c. Then pass the wires at the end of the turnbuckle in opposite directions through the hole in the turnbuckle eyes or between the jaws of the turnbuckle fork, as applicable, laying one wire along the barrel and wrapping the other at least four times around the shank of the turnbuckle and binding the laid wires in place before cutting the wrapped wire off. d. Wrap the remaining length of safety wire at least four turns around the shank and cut it off. Repeat the procedure at the opposite end of the turnbuckle. e. When a swaged terminal is being safetied, pass the ends of both wires through the hole provided in the terminal for this pur- pose and wrap both ends around the shank as previously described. If the hole is not large enough to allow passage of both wires, pass the wire through the hole and loop it over the free end of the other wire, and then wrap both ends around the shank as previously described. Another satisfactory double-wrap method is similar to the previous method, except that the spiraling of the wires is omitted as shown in figure 7-26(B). 7-181. SINGLE-WRAP METHOD. The single-wrap methods described in the follow- ing paragraphs and as illustrated in figure 7- 26(C) and (D) are acceptable, but are not the equal of the double-wrap methods. a. Pass a single length of wire through the cable eye or fork, or through the hole in the swaged terminal at either end of the turnbuckle assembly. Spiral each of the wire ends in op- posite directions around the first half of the turnbuckle barrel, so as to cross each other twice. Thread both wire ends through the hole in the middle of the barrel so that the third crossing of wire ends is in the hole, again, spi- ral the two wire ends in opposite directions around the remaining half of the turnbuckle, crossing them twice. Then, pass one wire end through the cable eye or fork, or through the hole in the swaged terminals, in the manner previously described. Wrap both wire ends around the shank for at least four turns each, cutting off excess wire. This method is shown in figure 7-26(C). Par 7-179 Page 7-43PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |