PDF Publication Title:

Text from PDF Page: 347

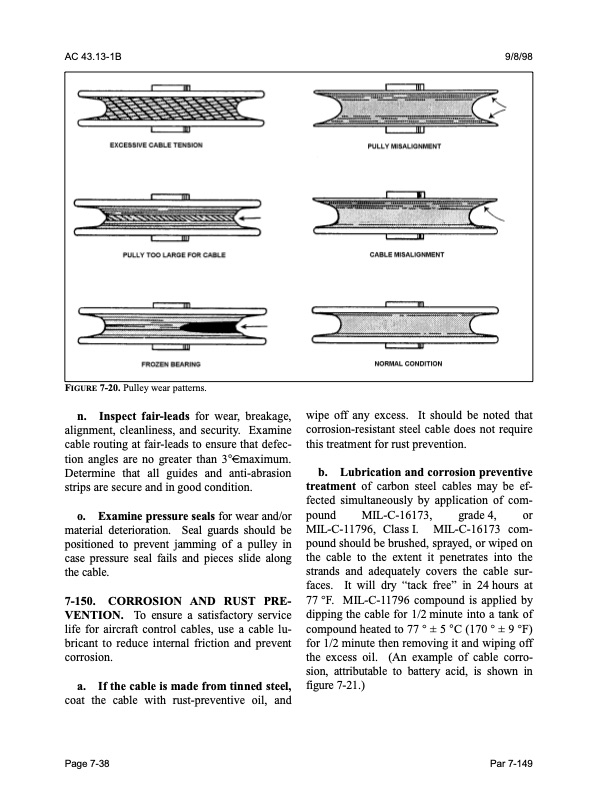

AC 43.13-1B 9/8/98 FIGURE 7-20. Pulley wear patterns. n. Inspect fair-leads for wear, breakage, alignment, cleanliness, and security. Examine cable routing at fair-leads to ensure that defec tion angles are no greater than 3°€maximum. Determine that all guides and anti-abrasion strips are secure and in good condition. o. Examine pressure seals for wear and/or material deterioration. Seal guards should be positioned to prevent jamming of a pulley in case pressure seal fails and pieces slide along the cable. 7-150. CORROSION AND RUST PRE- VENTION. To ensure a satisfactory service life for aircraft control cables, use a cable lu bricant to reduce internal friction and prevent corrosion. a. If the cable is made from tinned steel, coat the cable with rust-preventive oil, and wipe off any excess. It should be noted that corrosion-resistant steel cable does not require this treatment for rust prevention. b. Lubrication and corrosion preventive treatment of carbon steel cables may be ef fected simultaneously by application of com pound MIL-C-16173, grade 4, or MIL-C-11796, Class I. MIL-C-16173 com pound should be brushed, sprayed, or wiped on the cable to the extent it penetrates into the strands and adequately covers the cable sur faces. It will dry “tack free” in 24 hours at 77 °F. MIL-C-11796 compound is applied by dipping the cable for 1/2 minute into a tank of compoundheatedto77°±5°C(170°±9°F) for 1/2 minute then removing it and wiping off the excess oil. (An example of cable corro sion, attributable to battery acid, is shown in figure 7-21.) Page 7-38 Par 7-149PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |