PDF Publication Title:

Text from PDF Page: 346

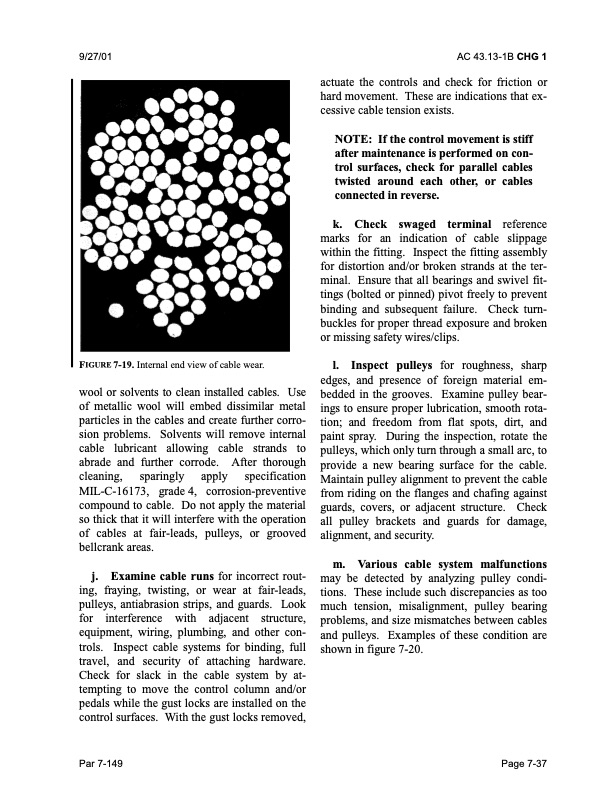

9/27/01 AC 43.13-1B CHG 1 FIGURE 7-19. Internal end view of cable wear. wool or solvents to clean installed cables. Use of metallic wool will embed dissimilar metal particles in the cables and create further corro sion problems. Solvents will remove internal cable lubricant allowing cable strands to abrade and further corrode. After thorough cleaning, sparingly apply specification MIL-C-16173, grade 4, corrosion-preventive compound to cable. Do not apply the material so thick that it will interfere with the operation of cables at fair-leads, pulleys, or grooved bellcrank areas. j. Examine cable runs for incorrect rout ing, fraying, twisting, or wear at fair-leads, pulleys, antiabrasion strips, and guards. Look for interference with adjacent structure, equipment, wiring, plumbing, and other con trols. Inspect cable systems for binding, full travel, and security of attaching hardware. Check for slack in the cable system by at tempting to move the control column and/or pedals while the gust locks are installed on the control surfaces. With the gust locks removed, actuate the controls and check for friction or hard movement. These are indications that ex cessive cable tension exists. NOTE: If the control movement is stiff after maintenance is performed on con- trol surfaces, check for parallel cables twisted around each other, or cables connected in reverse. k. Check swaged terminal reference marks for an indication of cable slippage within the fitting. Inspect the fitting assembly for distortion and/or broken strands at the ter minal. Ensure that all bearings and swivel fit tings (bolted or pinned) pivot freely to prevent binding and subsequent failure. Check turn buckles for proper thread exposure and broken or missing safety wires/clips. l. Inspect pulleys for roughness, sharp edges, and presence of foreign material em bedded in the grooves. Examine pulley bear ings to ensure proper lubrication, smooth rota tion; and freedom from flat spots, dirt, and paint spray. During the inspection, rotate the pulleys, which only turn through a small arc, to provide a new bearing surface for the cable. Maintain pulley alignment to prevent the cable from riding on the flanges and chafing against guards, covers, or adjacent structure. Check all pulley brackets and guards for damage, alignment, and security. m. Various cable system malfunctions may be detected by analyzing pulley condi tions. These include such discrepancies as too much tension, misalignment, pulley bearing problems, and size mismatches between cables and pulleys. Examples of these condition are shown in figure 7-20. Par 7-149 Page 7-37PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |