PDF Publication Title:

Text from PDF Page: 167

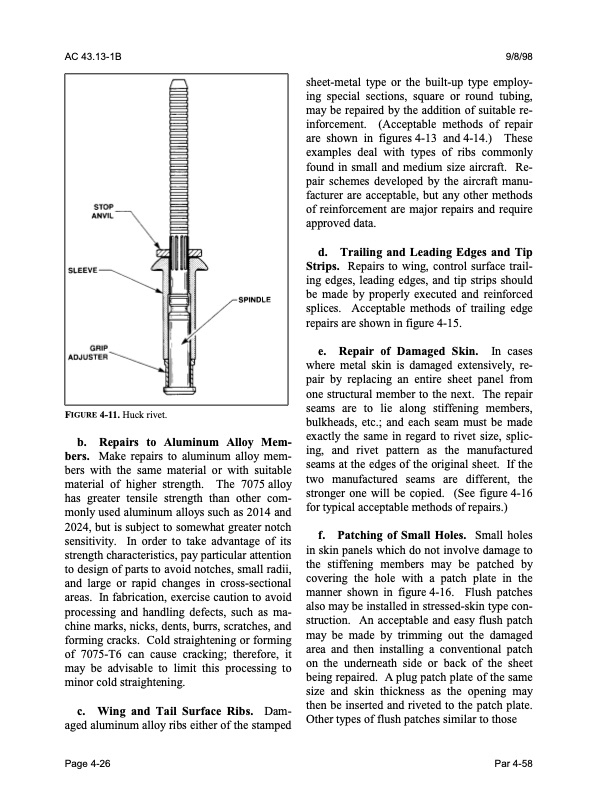

AC 43.13-1B 9/8/98 FIGURE 4-11. Huck rivet. b. Repairs to Aluminum Alloy Mem bers. Make repairs to aluminum alloy mem bers with the same material or with suitable material of higher strength. The 7075 alloy has greater tensile strength than other com monly used aluminum alloys such as 2014 and 2024, but is subject to somewhat greater notch sensitivity. In order to take advantage of its strength characteristics, pay particular attention to design of parts to avoid notches, small radii, and large or rapid changes in cross-sectional areas. In fabrication, exercise caution to avoid processing and handling defects, such as ma chine marks, nicks, dents, burrs, scratches, and forming cracks. Cold straightening or forming of 7075-T6 can cause cracking; therefore, it may be advisable to limit this processing to minor cold straightening. c. Wing and Tail Surface Ribs. Dam aged aluminum alloy ribs either of the stamped sheet-metal type or the built-up type employ ing special sections, square or round tubing, may be repaired by the addition of suitable re inforcement. (Acceptable methods of repair are shown in figures 4-13 and 4-14.) These examples deal with types of ribs commonly found in small and medium size aircraft. Re pair schemes developed by the aircraft manu facturer are acceptable, but any other methods of reinforcement are major repairs and require approved data. d. Trailing and Leading Edges and Tip Strips. Repairs to wing, control surface trail ing edges, leading edges, and tip strips should be made by properly executed and reinforced splices. Acceptable methods of trailing edge repairs are shown in figure 4-15. e. Repair of Damaged Skin. In cases where metal skin is damaged extensively, re pair by replacing an entire sheet panel from one structural member to the next. The repair seams are to lie along stiffening members, bulkheads, etc.; and each seam must be made exactly the same in regard to rivet size, splic ing, and rivet pattern as the manufactured seams at the edges of the original sheet. If the two manufactured seams are different, the stronger one will be copied. (See figure 4-16 for typical acceptable methods of repairs.) f. Patching of Small Holes. Small holes in skin panels which do not involve damage to the stiffening members may be patched by covering the hole with a patch plate in the manner shown in figure 4-16. Flush patches also may be installed in stressed-skin type con struction. An acceptable and easy flush patch may be made by trimming out the damaged area and then installing a conventional patch on the underneath side or back of the sheet being repaired. A plug patch plate of the same size and skin thickness as the opening may then be inserted and riveted to the patch plate. Other types of flush patches similar to those Page 4-26 Par 4-58PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |