PDF Publication Title:

Text from PDF Page: 166

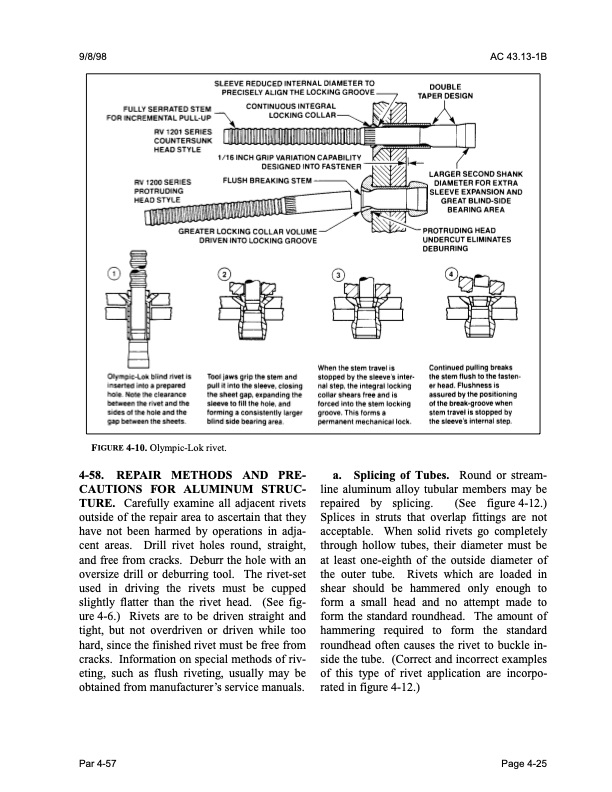

9/8/98 AC 43.13-1B FIGURE 4-10. Olympic-Lok rivet. 4-58. REPAIR METHODS AND PRE CAUTIONS FOR ALUMINUM STRUC TURE. Carefully examine all adjacent rivets outside of the repair area to ascertain that they have not been harmed by operations in adja cent areas. Drill rivet holes round, straight, and free from cracks. Deburr the hole with an oversize drill or deburring tool. The rivet-set used in driving the rivets must be cupped slightly flatter than the rivet head. (See fig ure 4-6.) Rivets are to be driven straight and tight, but not overdriven or driven while too hard, since the finished rivet must be free from cracks. Information on special methods of riv eting, such as flush riveting, usually may be obtained from manufacturer’s service manuals. a. Splicing of Tubes. Round or stream line aluminum alloy tubular members may be repaired by splicing. (See figure 4-12.) Splices in struts that overlap fittings are not acceptable. When solid rivets go completely through hollow tubes, their diameter must be at least one-eighth of the outside diameter of the outer tube. Rivets which are loaded in shear should be hammered only enough to form a small head and no attempt made to form the standard roundhead. The amount of hammering required to form the standard roundhead often causes the rivet to buckle in side the tube. (Correct and incorrect examples of this type of rivet application are incorpo rated in figure 4-12.) Par 4-57 Page 4-25PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |