PDF Publication Title:

Text from PDF Page: 165

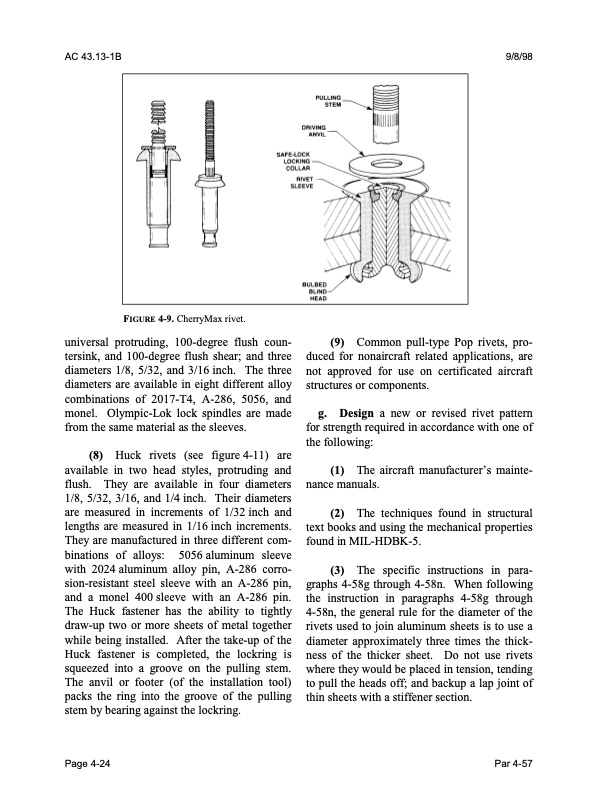

AC 43.13-1B 9/8/98 FIGURE 4-9. CherryMax rivet. universal protruding, 100-degree flush coun tersink, and 100-degree flush shear; and three diameters 1/8, 5/32, and 3/16 inch. The three diameters are available in eight different alloy combinations of 2017-T4, A-286, 5056, and monel. Olympic-Lok lock spindles are made from the same material as the sleeves. (8) Huck rivets (see figure 4-11) are available in two head styles, protruding and flush. They are available in four diameters 1/8, 5/32, 3/16, and 1/4 inch. Their diameters are measured in increments of 1/32 inch and lengths are measured in 1/16 inch increments. They are manufactured in three different com binations of alloys: 5056 aluminum sleeve with 2024 aluminum alloy pin, A-286 corro sion-resistant steel sleeve with an A-286 pin, and a monel 400 sleeve with an A-286 pin. The Huck fastener has the ability to tightly draw-up two or more sheets of metal together while being installed. After the take-up of the Huck fastener is completed, the lockring is squeezed into a groove on the pulling stem. The anvil or footer (of the installation tool) packs the ring into the groove of the pulling stem by bearing against the lockring. (9) Common pull-type Pop rivets, pro duced for nonaircraft related applications, are not approved for use on certificated aircraft structures or components. g. Design a new or revised rivet pattern for strength required in accordance with one of the following: (1) The aircraft manufacturer’s mainte nance manuals. (2) The techniques found in structural text books and using the mechanical properties found in MIL-HDBK-5. (3) The specific instructions in para graphs 4-58g through 4-58n. When following the instruction in paragraphs 4-58g through 4-58n, the general rule for the diameter of the rivets used to join aluminum sheets is to use a diameter approximately three times the thick ness of the thicker sheet. Do not use rivets where they would be placed in tension, tending to pull the heads off; and backup a lap joint of thin sheets with a stiffener section. Page 4-24 Par 4-57PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |