PDF Publication Title:

Text from PDF Page: 155

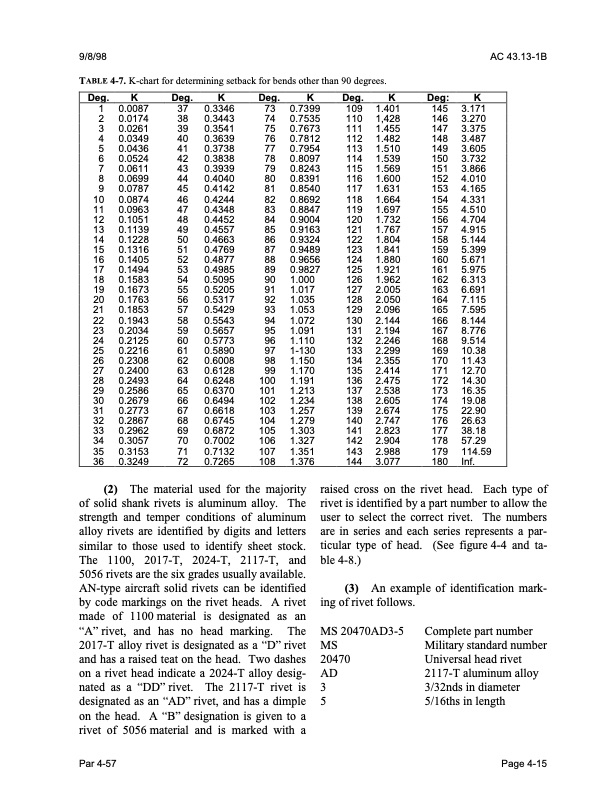

9/8/98 AC 43.13-1B TABLE 4-7. K-chart for determining setback for bends other than 90 degrees. Deg. K Deg. K Deg. K Deg. K Deg: K 1 0.0087 2 0.0174 3 0.0261 4 0.0349 5 0.0436 6 0.0524 7 0.0611 8 0.0699 9 0.0787 10 0.0874 11 0.0963 12 0.1051 13 0.1139 14 0.1228 15 0.1316 16 0.1405 17 0.1494 18 0.1583 19 0.1673 20 0.1763 21 0.1853 22 0.1943 23 0.2034 24 0.2125 25 0.2216 26 0.2308 27 0.2400 28 0.2493 29 0.2586 30 0.2679 31 0.2773 32 0.2867 33 0.2962 34 0.3057 35 0.3153 36 0.3249 37 0.3346 73 38 0.3443 74 39 0.3541 75 40 0.3639 76 41 0.3738 77 42 0.3838 78 43 0.3939 79 44 0.4040 80 45 0.4142 81 46 0.4244 82 47 0.4348 83 48 0.4452 84 49 0.4557 85 50 0.4663 86 51 0.4769 87 52 0.4877 88 53 0.4985 89 54 0.5095 90 55 0.5205 91 56 0.5317 92 57 0.5429 93 58 0.5543 94 59 0.5657 95 60 0.5773 96 61 0.5890 97 62 0.6008 98 63 0.6128 99 64 0.6248 100 65 0.6370 101 66 0.6494 102 67 0.6618 103 68 0.6745 104 69 0.6872 105 70 0.7002 106 71 0.7132 107 72 0.7265 108 0.7399 109 1.401 0.7535 110 1,428 0.7673 111 1.455 0.7812 112 1.482 0.7954 113 1.510 0.8097 114 1.539 0.8243 115 1.569 0.8391 116 1.600 0.8540 117 1.631 0.8692 118 1.664 0.8847 119 1.697 0.9004 120 1.732 0.9163 121 1.767 0.9324 122 1.804 0.9489 123 1.841 0.9656 124 1.880 0.9827 125 1.921 1.000 126 1.962 1.017 127 2.005 1.035 128 2.050 1.053 129 2.096 1.072 130 2.144 1.091 131 2.194 1.110 132 2.246 1-130 133 2.299 1.150 134 2.355 1.170 135 2.414 1.191 136 2.475 1.213 137 2.538 1.234 138 2.605 1.257 139 2.674 1.279 140 2.747 1.303 141 2.823 1.327 142 2.904 1.351 143 2.988 1.376 144 3.077 145 3.171 146 3.270 147 3.375 148 3.487 149 3.605 150 3.732 151 3.866 152 4.010 153 4.165 154 4.331 155 4.510 156 4.704 157 4.915 158 5.144 159 5.399 160 5.671 161 5.975 162 6.313 163 6.691 164 7.115 165 7.595 166 8.144 167 8.776 168 9.514 169 10.38 170 11.43 171 12.70 172 14.30 173 16.35 174 19.08 175 22.90 176 26.63 177 38.18 178 57.29 179 114.59 180 Inf. material used for the majority rivets is aluminum alloy. The strength and temper conditions of aluminum alloy rivets are identified by digits and letters similar to those used to identify sheet stock. raised cross on the rivet head. Each type of rivet is identified by a part number to allow the user to select the correct rivet. The numbers are in series and each series represents a par ticular type of head. (See figure 4-4 and ta (2) The of solid shank The 1100, 2017-T, 2024-T, 2117-T, and ble4-8.) 5056 rivets are the six grades usually available. AN-type aircraft solid rivets can be identified (3) An example of identification mark by code markings on the rivet heads. A rivet made of 1100material is designated as an “A” rivet, and has no head marking. The 2017-T alloy rivet is designated as a “D” rivet and has a raised teat on the head. Two dashes on a rivet head indicate a 2024-T alloy desig nated as a “DD” rivet. The 2117-T rivet is designated as an “AD” rivet, and has a dimple on the head. A “B” designation is given to a rivet of 5056 material and is marked with a ing of rivet follows. MS 20470AD3-5 MS 20470 AD 3 5 Complete part number Military standard number Universal head rivet 2117-T aluminum alloy 3/32nds in diameter 5/16ths in length Par 4-57 Page 4-15PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |