PDF Publication Title:

Text from PDF Page: 156

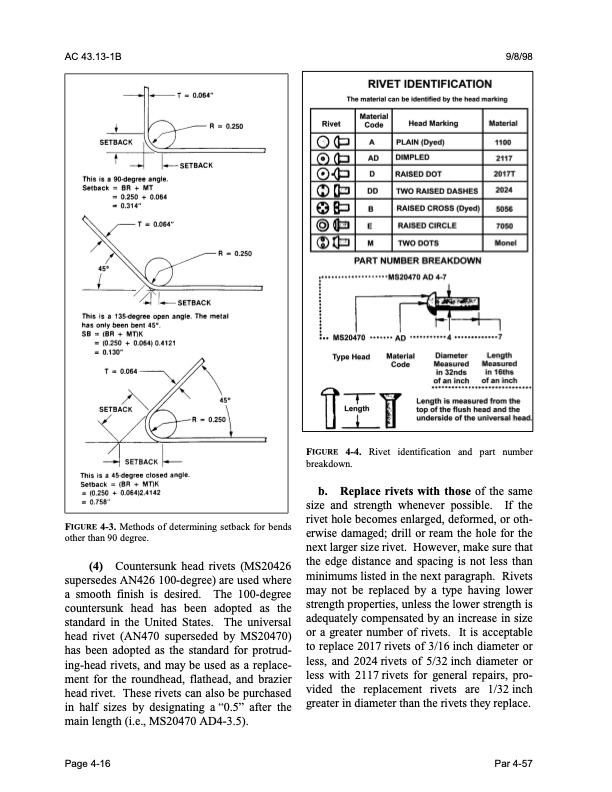

AC 43.13-1B 9/8/98 FIGURE 4-3. Methods of determining setback for bends other than 90 degree. (4) Countersunk head rivets (MS20426 supersedes AN426 100-degree) are used where a smooth finish is desired. The 100-degree countersunk head has been adopted as the standard in the United States. The universal head rivet (AN470 superseded by MS20470) has been adopted as the standard for protrud ing-head rivets, and may be used as a replace ment for the roundhead, flathead, and brazier head rivet. These rivets can also be purchased in half sizes by designating a “0.5” after the main length (i.e., MS20470 AD4-3.5). FIGURE 4-4. Rivet identification and part number breakdown. b. Replace rivets with those of the same size and strength whenever possible. If the rivet hole becomes enlarged, deformed, or oth erwise damaged; drill or ream the hole for the next larger size rivet. However, make sure that the edge distance and spacing is not less than minimums listed in the next paragraph. Rivets may not be replaced by a type having lower strength properties, unless the lower strength is adequately compensated by an increase in size or a greater number of rivets. It is acceptable to replace 2017 rivets of 3/16 inch diameter or less, and 2024 rivets of 5/32 inch diameter or less with 2117 rivets for general repairs, pro vided the replacement rivets are 1/32 inch greater in diameter than the rivets they replace. Page 4-16 Par 4-57PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |