PDF Publication Title:

Text from PDF Page: 154

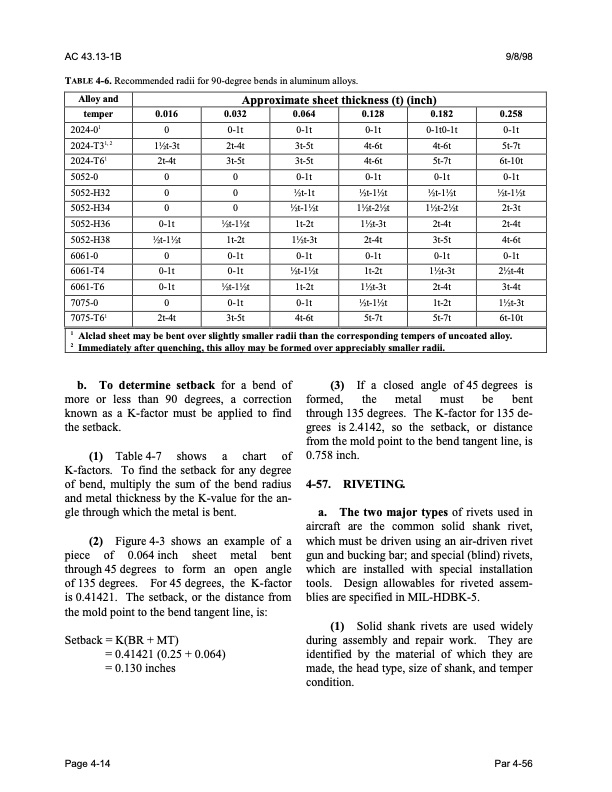

AC 43.13-1B 9/8/98 TABLE 4-6. Recommended radii for 90-degree bends in aluminum alloys. Alloy and temper 2024-01 2024-T31, 2 2024-T61 5052-0 5052-H32 5052-H34 5052-H36 5052-H38 6061-0 6061-T4 6061-T6 7075-0 7075-T61 Approximate sheet thickness (t) (inch) 0.016 0.032 0 0-1t 11⁄2t-3t 2t-4t 2t-4t 3t-5t 0 0 0 0 0 0 0-1t 1⁄2t-11⁄2t 1⁄2t-11⁄2t 1t-2t 0 0-1t 0-1t 0-1t 0-1t 1⁄2t-11⁄2t 0 0-1t 2t-4t 3t-5t 0.064 0-1t 3t-5t 3t-5t 0-1t 1⁄2t-1t 1⁄2t-11⁄2t 1t-2t 11⁄2t-3t 0-1t 1⁄2t-11⁄2t 1t-2t 0-1t 4t-6t 0.128 0-1t 4t-6t 4t-6t 0-1t 1⁄2t-11⁄2t 11⁄2t-21⁄2t 11⁄2t-3t 2t-4t 0-1t 1t-2t 11⁄2t-3t 1⁄2t-11⁄2t 5t-7t 0.182 0-1t0-1t 4t-6t 5t-7t 0-1t 1⁄2t-11⁄2t 11⁄2t-21⁄2t 2t-4t 3t-5t 0-1t 11⁄2t-3t 2t-4t 1t-2t 5t-7t 0.258 0-1t 5t-7t 6t-10t 0-1t 1⁄2t-11⁄2t 2t-3t 2t-4t 4t-6t 0-1t 21⁄2t-4t 3t-4t 11⁄2t-3t 6t-10t 1 Alclad sheet may be bent over slightly smaller radii than the corresponding tempers of uncoated alloy. 2 Immediately after quenching, this alloy may be formed over appreciably smaller radii. b. To determine setback for a bend of more or less than 90 degrees, a correction known as a K-factor must be applied to find the setback. (1) Table 4-7 shows a chart of K-factors. To find the setback for any degree of bend, multiply the sum of the bend radius and metal thickness by the K-value for the an gle through which the metal is bent. (2) Figure 4-3 shows an example of a piece of 0.064 inch sheet metal bent through 45 degrees to form an open angle of 135 degrees. For 45 degrees, the K-factor is 0.41421. The setback, or the distance from the mold point to the bend tangent line, is: Setback = K(BR + MT) = 0.41421 (0.25 + 0.064) = 0.130 inches (3) If a closed angle of 45 degrees is formed, the metal must be bent through 135 degrees. The K-factor for 135 de grees is 2.4142, so the setback, or distance from the mold point to the bend tangent line, is 0.758 inch. 4-57. RIVETING. a. The two major types of rivets used in aircraft are the common solid shank rivet, which must be driven using an air-driven rivet gun and bucking bar; and special (blind) rivets, which are installed with special installation tools. Design allowables for riveted assem blies are specified in MIL-HDBK-5. (1) Solid shank rivets are used widely during assembly and repair work. They are identified by the material of which they are made, the head type, size of shank, and temper condition. Page 4-14 Par 4-56PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |