PDF Publication Title:

Text from PDF Page: 153

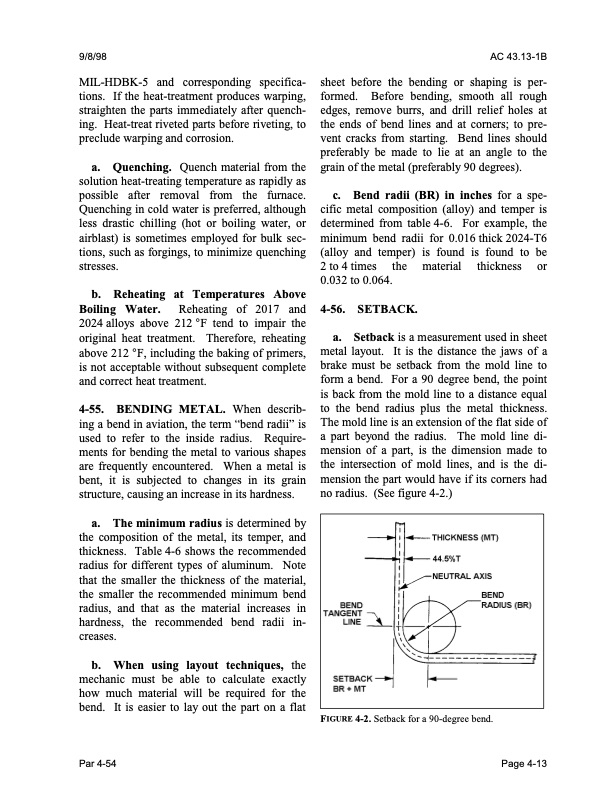

9/8/98 AC 43.13-1B MIL-HDBK-5 and corresponding specifica tions. If the heat-treatment produces warping, straighten the parts immediately after quench ing. Heat-treat riveted parts before riveting, to preclude warping and corrosion. a. Quenching. Quench material from the solution heat-treating temperature as rapidly as possible after removal from the furnace. Quenching in cold water is preferred, although less drastic chilling (hot or boiling water, or airblast) is sometimes employed for bulk sec tions, such as forgings, to minimize quenching stresses. b. Reheating at Temperatures Above Boiling Water. Reheating of 2017 and 2024 alloys above 212 °F tend to impair the original heat treatment. Therefore, reheating above 212 °F, including the baking of primers, is not acceptable without subsequent complete and correct heat treatment. 4-55. BENDING METAL. When describ ing a bend in aviation, the term “bend radii” is used to refer to the inside radius. Require ments for bending the metal to various shapes are frequently encountered. When a metal is bent, it is subjected to changes in its grain structure, causing an increase in its hardness. a. The minimum radius is determined by the composition of the metal, its temper, and thickness. Table 4-6 shows the recommended radius for different types of aluminum. Note that the smaller the thickness of the material, the smaller the recommended minimum bend radius, and that as the material increases in hardness, the recommended bend radii in creases. b. When using layout techniques, the mechanic must be able to calculate exactly how much material will be required for the bend. It is easier to lay out the part on a flat sheet before the bending or shaping is per formed. Before bending, smooth all rough edges, remove burrs, and drill relief holes at the ends of bend lines and at corners; to pre vent cracks from starting. Bend lines should preferably be made to lie at an angle to the grain of the metal (preferably 90 degrees). c. Bend radii (BR) in inches for a spe cific metal composition (alloy) and temper is determined from table 4-6. For example, the minimum bend radii for 0.016 thick 2024-T6 (alloy and temper) is found is found to be 2 to 4 times the material thickness or 0.032 to 0.064. 4-56. SETBACK. a. Setback is a measurement used in sheet metal layout. It is the distance the jaws of a brake must be setback from the mold line to form a bend. For a 90 degree bend, the point is back from the mold line to a distance equal to the bend radius plus the metal thickness. The mold line is an extension of the flat side of a part beyond the radius. The mold line di mension of a part, is the dimension made to the intersection of mold lines, and is the di mension the part would have if its corners had no radius. (See figure 4-2.) FIGURE 4-2. Setback for a 90-degree bend. Par 4-54 Page 4-13PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |