PDF Publication Title:

Text from PDF Page: 147

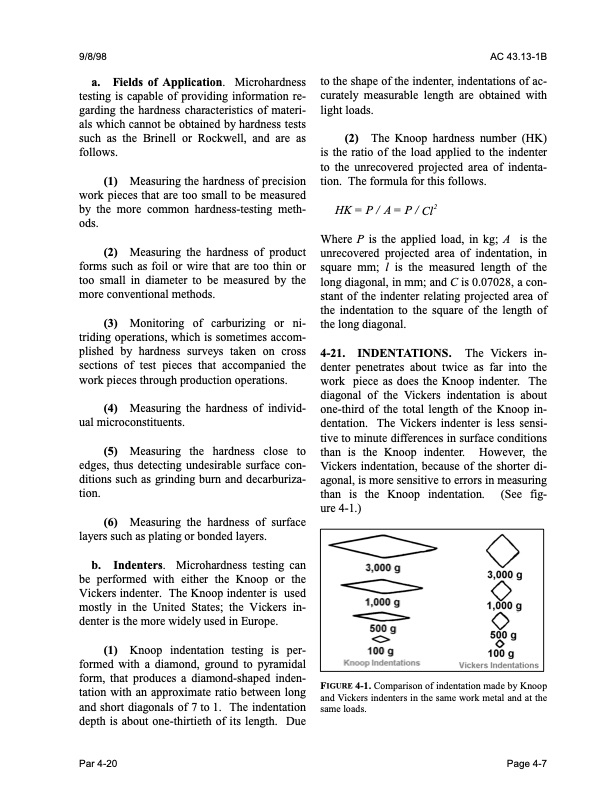

9/8/98 AC 43.13-1B a. Fields of Application. Microhardness testing is capable of providing information re garding the hardness characteristics of materi als which cannot be obtained by hardness tests such as the Brinell or Rockwell, and are as follows. (1) Measuring the hardness of precision work pieces that are too small to be measured by the more common hardness-testing meth ods. (2) Measuring the hardness of product forms such as foil or wire that are too thin or too small in diameter to be measured by the more conventional methods. (3) Monitoring of carburizing or ni triding operations, which is sometimes accom plished by hardness surveys taken on cross sections of test pieces that accompanied the work pieces through production operations. (4) Measuring the hardness of individ ual microconstituents. (5) Measuring the hardness close to edges, thus detecting undesirable surface con ditions such as grinding burn and decarburiza tion. (6) Measuring the hardness of surface layers such as plating or bonded layers. b. Indenters. Microhardness testing can be performed with either the Knoop or the Vickers indenter. The Knoop indenter is used mostly in the United States; the Vickers in denter is the more widely used in Europe. (1) Knoop indentation testing is per formed with a diamond, ground to pyramidal form, that produces a diamond-shaped inden tation with an approximate ratio between long and short diagonals of 7 to 1. The indentation depth is about one-thirtieth of its length. Due to the shape of the indenter, indentations of ac curately measurable length are obtained with light loads. (2) The Knoop hardness number (HK) is the ratio of the load applied to the indenter to the unrecovered projected area of indenta tion. The formula for this follows. HK=P/ A=P/Cl2 Where P is the applied load, in kg; A is the unrecovered projected area of indentation, in square mm; l is the measured length of the long diagonal, in mm; and C is 0.07028, a con stant of the indenter relating projected area of the indentation to the square of the length of the long diagonal. 4-21. INDENTATIONS. The Vickers in denter penetrates about twice as far into the work piece as does the Knoop indenter. The diagonal of the Vickers indentation is about one-third of the total length of the Knoop in dentation. The Vickers indenter is less sensi tive to minute differences in surface conditions than is the Knoop indenter. However, the Vickers indentation, because of the shorter di agonal, is more sensitive to errors in measuring than is the Knoop indentation. (See fig ure 4-1.) FIGURE 4-1. Comparison of indentation made by Knoop and Vickers indenters in the same work metal and at the same loads. Par 4-20 Page 4-7PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |