PDF Publication Title:

Text from PDF Page: 148

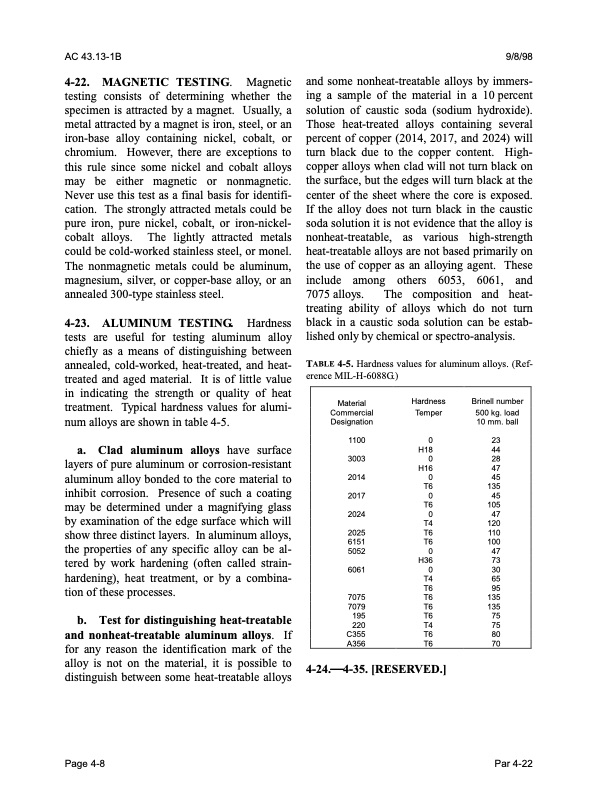

AC 43.13-1B 9/8/98 4-22. MAGNETIC TESTING. Magnetic testing consists of determining whether the specimen is attracted by a magnet. Usually, a metal attracted by a magnet is iron, steel, or an iron-base alloy containing nickel, cobalt, or chromium. However, there are exceptions to this rule since some nickel and cobalt alloys may be either magnetic or nonmagnetic. Never use this test as a final basis for identifi cation. The strongly attracted metals could be pure iron, pure nickel, cobalt, or iron-nickel cobalt alloys. The lightly attracted metals could be cold-worked stainless steel, or monel. The nonmagnetic metals could be aluminum, magnesium, silver, or copper-base alloy, or an annealed 300-type stainless steel. 4-23. ALUMINUM TESTING. Hardness tests are useful for testing aluminum alloy chiefly as a means of distinguishing between annealed, cold-worked, heat-treated, and heat- treated and aged material. It is of little value in indicating the strength or quality of heat treatment. Typical hardness values for alumi num alloys are shown in table 4-5. a. Clad aluminum alloys have surface layers of pure aluminum or corrosion-resistant aluminum alloy bonded to the core material to inhibit corrosion. Presence of such a coating may be determined under a magnifying glass by examination of the edge surface which will show three distinct layers. In aluminum alloys, the properties of any specific alloy can be al tered by work hardening (often called strain- hardening), heat treatment, or by a combina tion of these processes. b. Test for distinguishing heat-treatable and nonheat-treatable aluminum alloys. If for any reason the identification mark of the alloy is not on the material, it is possible to distinguish between some heat-treatable alloys and some nonheat-treatable alloys by immers ing a sample of the material in a 10 percent solution of caustic soda (sodium hydroxide). Those heat-treated alloys containing several percent of copper (2014, 2017, and 2024) will turn black due to the copper content. High- copper alloys when clad will not turn black on the surface, but the edges will turn black at the center of the sheet where the core is exposed. If the alloy does not turn black in the caustic soda solution it is not evidence that the alloy is nonheat-treatable, as various high-strength heat-treatable alloys are not based primarily on the use of copper as an alloying agent. These include among others 6053, 6061, and 7075 alloys. The composition and heat- treating ability of alloys which do not turn black in a caustic soda solution can be estab lished only by chemical or spectro-analysis. TABLE 4-5. Hardness values for aluminum alloys. (Ref erence MIL-H-6088G.) Material Hardness Commercial Temper Designation 1100 0 H18 3003 0 H16 2014 0 T6 2017 0 T6 2024 0 T4 2025 T6 6151 T6 5052 0 H36 6061 0 T4 T6 7075 T6 7079 T6 195 T6 220 T4 C355 T6 A356 T6 4-24.4-35. [RESERVED.] Brinell number 500 kg. load 10 mm. ball 23 44 28 47 45 135 45 105 47 120 110 100 47 73 30 65 95 135 135 75 75 80 70 Page 4-8 Par 4-22PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |