PDF Publication Title:

Text from PDF Page: 146

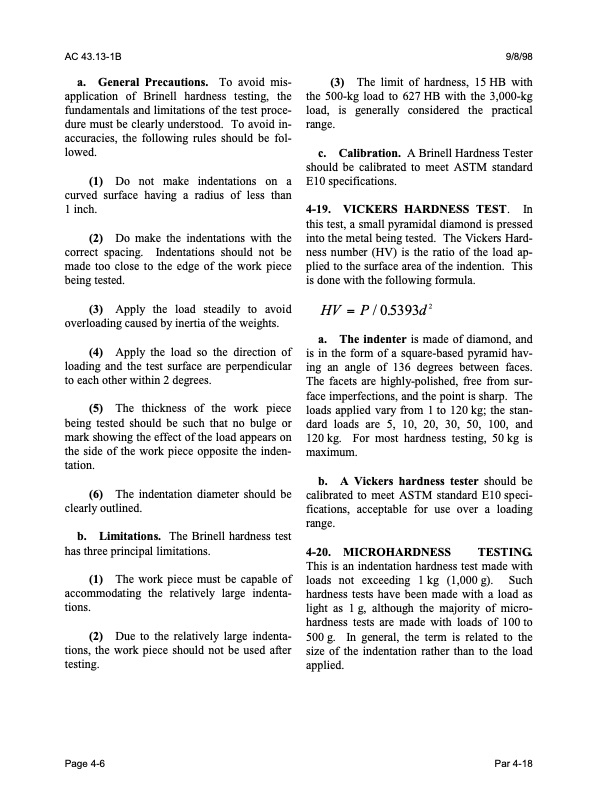

AC 43.13-1B 9/8/98 a. General Precautions. To avoid mis application of Brinell hardness testing, the fundamentals and limitations of the test proce dure must be clearly understood. To avoid in accuracies, the following rules should be fol lowed. (1) Do not make indentations on a curved surface having a radius of less than 1 inch. (2) Do make the indentations with the correct spacing. Indentations should not be made too close to the edge of the work piece being tested. (3) Apply the load steadily to avoid overloading caused by inertia of the weights. (4) Apply the load so the direction of loading and the test surface are perpendicular to each other within 2 degrees. (5) The thickness of the work piece being tested should be such that no bulge or mark showing the effect of the load appears on the side of the work piece opposite the inden tation. (6) The indentation diameter should be clearly outlined. b. Limitations. The Brinell hardness test has three principal limitations. (1) The work piece must be capable of accommodating the relatively large indenta tions. (2) Due to the relatively large indenta tions, the work piece should not be used after testing. (3) The limit of hardness, 15 HB with the 500-kg load to 627 HB with the 3,000-kg load, is generally considered the practical range. c. Calibration. A Brinell Hardness Tester should be calibrated to meet ASTM standard E10specifications. 4-19. VICKERS HARDNESS TEST. In this test, a small pyramidal diamond is pressed into the metal being tested. The Vickers Hard ness number (HV) is the ratio of the load ap plied to the surface area of the indention. This is done with the following formula. HV = P / 0.5393d 2 a. The indenter is made of diamond, and is in the form of a square-based pyramid hav ing an angle of 136 degrees between faces. The facets are highly-polished, free from sur face imperfections, and the point is sharp. The loads applied vary from 1 to 120 kg; the stan dard loads are 5, 10, 20, 30, 50, 100, and 120 kg. For most hardness testing, 50 kg is maximum. b. A Vickers hardness tester should be calibrated to meet ASTM standard E10 speci fications, acceptable for use over a loading range. 4-20. MICROHARDNESS TESTING. This is an indentation hardness test made with loads not exceeding 1 kg (1,000 g). Such hardness tests have been made with a load as light as 1 g, although the majority of micro- hardness tests are made with loads of 100 to 500 g. In general, the term is related to the size of the indentation rather than to the load applied. Page 4-6 Par 4-18PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |