PDF Publication Title:

Text from PDF Page: 145

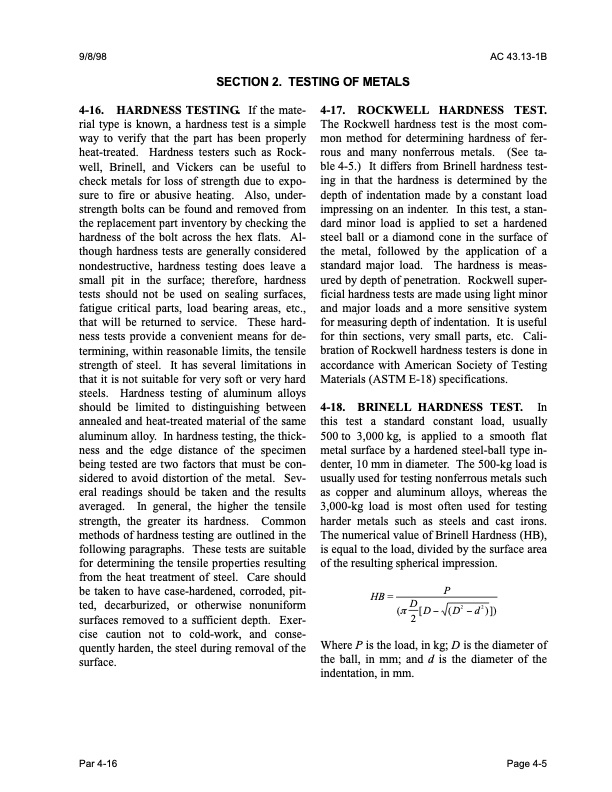

9/8/98 AC 43.13-1B 4-16. HARDNESS TESTING. If the mate rial type is known, a hardness test is a simple way to verify that the part has been properly heat-treated. Hardness testers such as Rock well, Brinell, and Vickers can be useful to check metals for loss of strength due to expo sure to fire or abusive heating. Also, under strength bolts can be found and removed from the replacement part inventory by checking the hardness of the bolt across the hex flats. Al though hardness tests are generally considered nondestructive, hardness testing does leave a small pit in the surface; therefore, hardness tests should not be used on sealing surfaces, fatigue critical parts, load bearing areas, etc., that will be returned to service. These hard ness tests provide a convenient means for de termining, within reasonable limits, the tensile strength of steel. It has several limitations in that it is not suitable for very soft or very hard steels. Hardness testing of aluminum alloys should be limited to distinguishing between annealed and heat-treated material of the same aluminum alloy. In hardness testing, the thick ness and the edge distance of the specimen being tested are two factors that must be con sidered to avoid distortion of the metal. Sev eral readings should be taken and the results averaged. In general, the higher the tensile strength, the greater its hardness. Common methods of hardness testing are outlined in the following paragraphs. These tests are suitable for determining the tensile properties resulting from the heat treatment of steel. Care should be taken to have case-hardened, corroded, pit ted, decarburized, or otherwise nonuniform surfaces removed to a sufficient depth. Exer cise caution not to cold-work, and conse quently harden, the steel during removal of the surface. 4-17. ROCKWELL HARDNESS TEST. The Rockwell hardness test is the most com mon method for determining hardness of fer rous and many nonferrous metals. (See ta ble 4-5.) It differs from Brinell hardness test ing in that the hardness is determined by the depth of indentation made by a constant load impressing on an indenter. In this test, a stan dard minor load is applied to set a hardened steel ball or a diamond cone in the surface of the metal, followed by the application of a standard major load. The hardness is meas ured by depth of penetration. Rockwell super ficial hardness tests are made using light minor and major loads and a more sensitive system for measuring depth of indentation. It is useful for thin sections, very small parts, etc. Cali bration of Rockwell hardness testers is done in accordance with American Society of Testing Materials (ASTM E-18) specifications. 4-18. BRINELL HARDNESS TEST. In this test a standard constant load, usually 500 to 3,000 kg, is applied to a smooth flat metal surface by a hardened steel-ball type in denter, 10 mm in diameter. The 500-kg load is usually used for testing nonferrous metals such as copper and aluminum alloys, whereas the 3,000-kg load is most often used for testing harder metals such as steels and cast irons. The numerical value of Brinell Hardness (HB), is equal to the load, divided by the surface area of the resulting spherical impression. HB= P (πD[D− (D2 −d2)]) 2 Where P is the load, in kg; D is the diameter of the ball, in mm; and d is the diameter of the indentation, in mm. SECTION 2. TESTING OF METALS Par 4-16 Page 4-5PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |