PDF Publication Title:

Text from PDF Page: 036

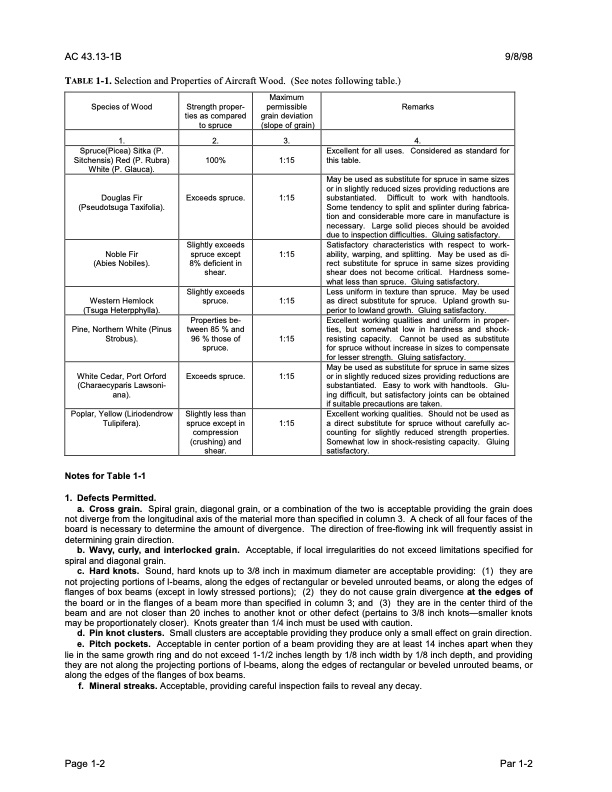

AC 43.13-1B 9/8/98 TABLE 1-1. Selection and Properties of Aircraft Wood. (See notes following table.) (slope of grain) 100% 1:15 to spruce Maximum permissible grain deviation Remarks 1. 2. 3. 4. Species of Wood Strength proper- ties as compared Spruce(Picea) Sitka (P. Sitchensis) Red (P. Rubra) White (P. Glauca). Excellent for all uses. Considered as standard for this table. Douglas Fir (Pseudotsuga Taxifolia). Exceeds spruce. 1:15 May be used as substitute for spruce in same sizes or in slightly reduced sizes providing reductions are substantiated. Difficult to work with handtools. Some tendency to split and splinter during fabrica- tion and considerable more care in manufacture is necessary. Large solid pieces should be avoided due to inspection difficulties. Gluing satisfactory. Noble Fir (Abies Nobiles). Slightly exceeds spruce except 8% deficient in shear. 1:15 Satisfactory characteristics with respect to work- ability, warping, and splitting. May be used as di- rect substitute for spruce in same sizes providing shear does not become critical. Hardness some- what less than spruce. Gluing satisfactory. Western Hemlock (Tsuga Heterpphylla). Slightly exceeds spruce. 1:15 Less uniform in texture than spruce. May be used as direct substitute for spruce. Upland growth su- perior to lowland growth. Gluing satisfactory. Pine, Northern White (Pinus Strobus). Properties be- tween 85 % and 96 % those of spruce. 1:15 Excellent working qualities and uniform in proper- ties, but somewhat low in hardness and shock- resisting capacity. Cannot be used as substitute for spruce without increase in sizes to compensate for lesser strength. Gluing satisfactory. White Cedar, Port Orford (Charaecyparis Lawsoni- ana). Exceeds spruce. 1:15 May be used as substitute for spruce in same sizes or in slightly reduced sizes providing reductions are substantiated. Easy to work with handtools. Glu- ing difficult, but satisfactory joints can be obtained if suitable precautions are taken. Poplar, Yellow (Liriodendrow Tulipifera). Slightly less than spruce except in compression (crushing) and shear. 1:15 Excellent working qualities. Should not be used as a direct substitute for spruce without carefully ac- counting for slightly reduced strength properties. Somewhat low in shock-resisting capacity. Gluing satisfactory. Notes for Table 1-1 1. Defects Permitted. a. Cross grain. Spiral grain, diagonal grain, or a combination of the two is acceptable providing the grain does not diverge from the longitudinal axis of the material more than specified in column 3. A check of all four faces of the board is necessary to determine the amount of divergence. The direction of free-flowing ink will frequently assist in determining grain direction. b. Wavy, curly, and interlocked grain. Acceptable, if local irregularities do not exceed limitations specified for spiral and diagonal grain. c. Hard knots. Sound, hard knots up to 3/8 inch in maximum diameter are acceptable providing: (1) they are not projecting portions of I-beams, along the edges of rectangular or beveled unrouted beams, or along the edges of flanges of box beams (except in lowly stressed portions); (2) they do not cause grain divergence at the edges of the board or in the flanges of a beam more than specified in column 3; and (3) they are in the center third of the beam and are not closer than 20 inches to another knot or other defect (pertains to 3/8 inch knots—smaller knots may be proportionately closer). Knots greater than 1/4 inch must be used with caution. d. Pin knot clusters. Small clusters are acceptable providing they produce only a small effect on grain direction. e. Pitch pockets. Acceptable in center portion of a beam providing they are at least 14 inches apart when they lie in the same growth ring and do not exceed 1-1/2 inches length by 1/8 inch width by 1/8 inch depth, and providing they are not along the projecting portions of I-beams, along the edges of rectangular or beveled unrouted beams, or along the edges of the flanges of box beams. f. Mineral streaks. Acceptable, providing careful inspection fails to reveal any decay. Page 1-2 Par 1-2PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |