PDF Publication Title:

Text from PDF Page: 035

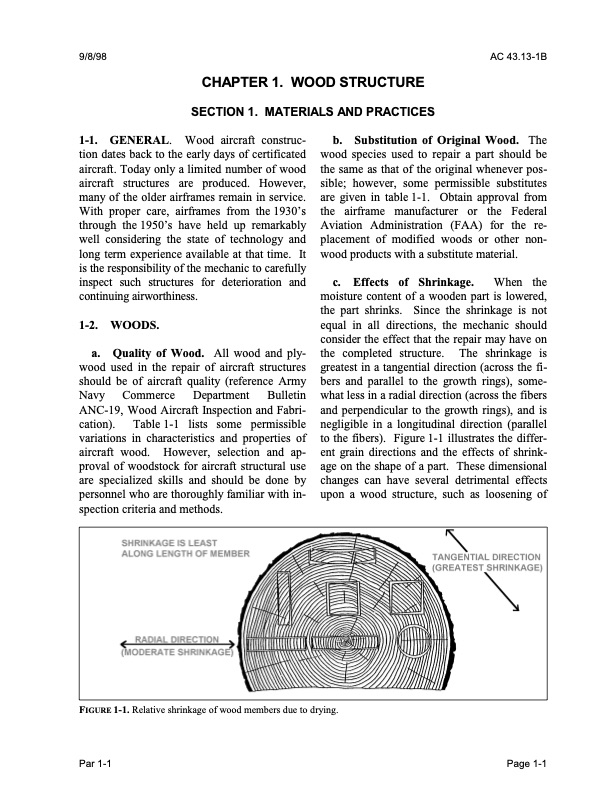

9/8/98 AC 43.13-1B CHAPTER 1. WOOD STRUCTURE SECTION 1. MATERIALS AND PRACTICES 1-1. GENERAL. Wood aircraft construc- tion dates back to the early days of certificated aircraft. Today only a limited number of wood aircraft structures are produced. However, many of the older airframes remain in service. With proper care, airframes from the 1930’s through the 1950’s have held up remarkably well considering the state of technology and long term experience available at that time. It is the responsibility of the mechanic to carefully inspect such structures for deterioration and continuing airworthiness. 1-2. WOODS. a. Quality of Wood. All wood and ply- wood used in the repair of aircraft structures should be of aircraft quality (reference Army Navy Commerce Department Bulletin ANC-19, Wood Aircraft Inspection and Fabri- cation). Table 1-1 lists some permissible variations in characteristics and properties of aircraft wood. However, selection and ap- proval of woodstock for aircraft structural use are specialized skills and should be done by personnel who are thoroughly familiar with in- spection criteria and methods. b. Substitution of Original Wood. The wood species used to repair a part should be the same as that of the original whenever pos- sible; however, some permissible substitutes are given in table 1-1. Obtain approval from the airframe manufacturer or the Federal Aviation Administration (FAA) for the re- placement of modified woods or other non- wood products with a substitute material. c. Effects of Shrinkage. When the moisture content of a wooden part is lowered, the part shrinks. Since the shrinkage is not equal in all directions, the mechanic should consider the effect that the repair may have on the completed structure. The shrinkage is greatest in a tangential direction (across the fi- bers and parallel to the growth rings), some- what less in a radial direction (across the fibers and perpendicular to the growth rings), and is negligible in a longitudinal direction (parallel to the fibers). Figure 1-1 illustrates the differ- ent grain directions and the effects of shrink- age on the shape of a part. These dimensional changes can have several detrimental effects upon a wood structure, such as loosening of FIGURE 1-1. Relative shrinkage of wood members due to drying. Par 1-1 Page 1-1PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |