PDF Publication Title:

Text from PDF Page: 014

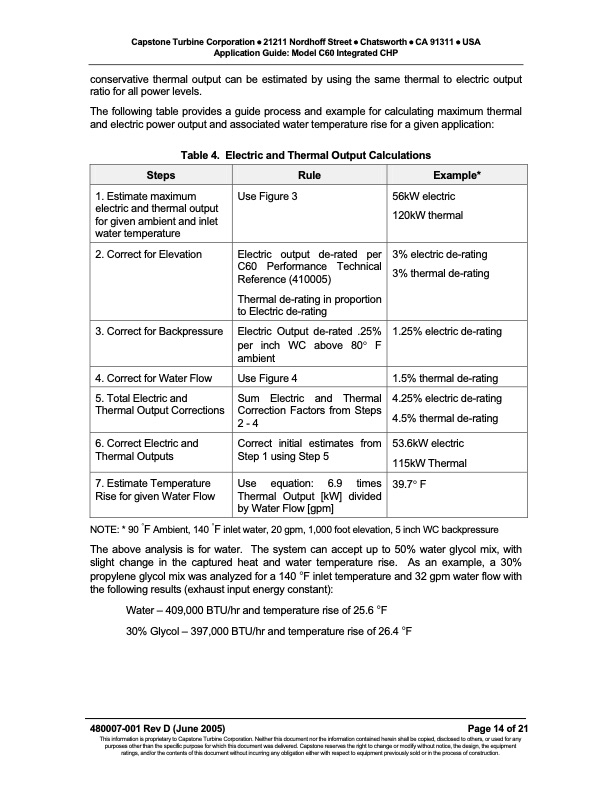

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: Model C60 Integrated CHP conservative thermal output can be estimated by using the same thermal to electric output ratio for all power levels. The following table provides a guide process and example for calculating maximum thermal and electric power output and associated water temperature rise for a given application: Table 4. Electric and Thermal Output Calculations Steps Rule Example* 1. Estimate maximum electric and thermal output for given ambient and inlet water temperature Use Figure 3 56kW electric 120kW thermal 2. Correct for Elevation Electric output de-rated per C60 Performance Technical Reference (410005) Thermal de-rating in proportion to Electric de-rating 3% electric de-rating 3% thermal de-rating 3. Correct for Backpressure Electric Output de-rated .25% per inch WC above 80° F ambient 1.25% electric de-rating 4. Correct for Water Flow 6. Correct Electric and Thermal Outputs Use Figure 4 1.5% thermal de-rating Correct initial estimates from 53.6kW electric 5. Total Electric and Thermal Output Corrections Sum Electric and Thermal Correction Factors from Steps 2-4 4.25% electric de-rating 4.5% thermal de-rating Step 1 using Step 5 115kW Thermal 7. Estimate Temperature Rise for given Water Flow Use equation: 6.9 times Thermal Output [kW] divided by Water Flow [gpm] 39.7° F NOTE: * 90 °F Ambient, 140 °F inlet water, 20 gpm, 1,000 foot elevation, 5 inch WC backpressure The above analysis is for water. The system can accept up to 50% water glycol mix, with slight change in the captured heat and water temperature rise. As an example, a 30% propylene glycol mix was analyzed for a 140 °F inlet temperature and 32 gpm water flow with the following results (exhaust input energy constant): Water – 409,000 BTU/hr and temperature rise of 25.6 °F 30% Glycol – 397,000 BTU/hr and temperature rise of 26.4 °F 480007-001 Rev D (June 2005) Page 14 of 21 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the equipment ratings, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Application Guide - Model C60 Integrated CHP (ICHP)

PDF Search Title:

Application Guide - Model C60 Integrated CHP (ICHP)Original File Name Searched:

480007_ICHP_AppGuide.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |