PDF Publication Title:

Text from PDF Page: 013

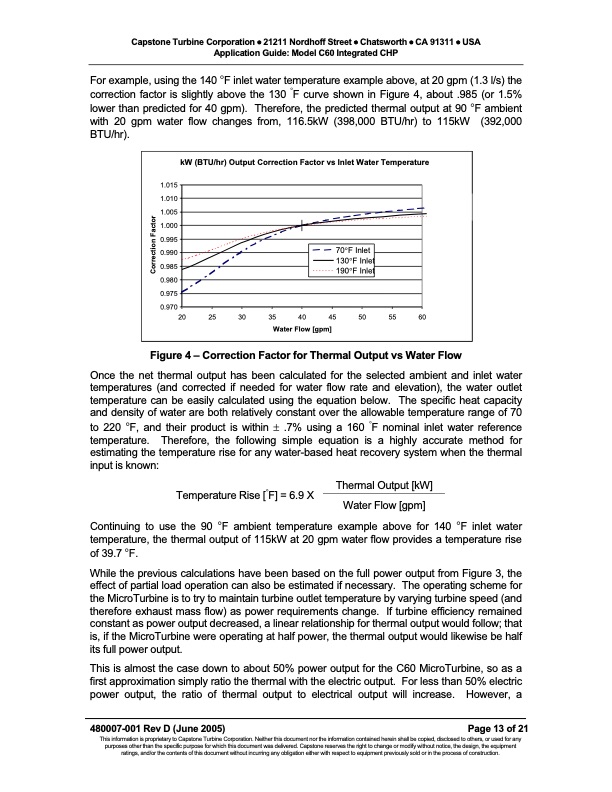

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: Model C60 Integrated CHP For example, using the 140 °F inlet water temperature example above, at 20 gpm (1.3 l/s) the correction factor is slightly above the 130 °F curve shown in Figure 4, about .985 (or 1.5% lower than predicted for 40 gpm). Therefore, the predicted thermal output at 90 °F ambient with 20 gpm water flow changes from, 116.5kW (398,000 BTU/hr) to 115kW (392,000 BTU/hr). kW (BTU/hr) Output Correction Factor vs Inlet Water Temperature 1.015 1.010 1.005 1.000 0.995 0.990 0.985 0.980 0.975 0.970 70°F Inlet 130°F Inlet 190°F Inlet 20 25 30 35 40 45 50 55 60 Water Flow [gpm] Figure 4 – Correction Factor for Thermal Output vs Water Flow Once the net thermal output has been calculated for the selected ambient and inlet water temperatures (and corrected if needed for water flow rate and elevation), the water outlet temperature can be easily calculated using the equation below. The specific heat capacity and density of water are both relatively constant over the allowable temperature range of 70 to 220 °F, and their product is within ± .7% using a 160 °F nominal inlet water reference temperature. Therefore, the following simple equation is a highly accurate method for estimating the temperature rise for any water-based heat recovery system when the thermal input is known: Temperature Rise [°F] = 6.9 X Thermal Output [kW] Water Flow [gpm] Continuing to use the 90 °F ambient temperature example above for 140 °F inlet water temperature, the thermal output of 115kW at 20 gpm water flow provides a temperature rise of 39.7 °F. While the previous calculations have been based on the full power output from Figure 3, the effect of partial load operation can also be estimated if necessary. The operating scheme for the MicroTurbine is to try to maintain turbine outlet temperature by varying turbine speed (and therefore exhaust mass flow) as power requirements change. If turbine efficiency remained constant as power output decreased, a linear relationship for thermal output would follow; that is, if the MicroTurbine were operating at half power, the thermal output would likewise be half its full power output. This is almost the case down to about 50% power output for the C60 MicroTurbine, so as a first approximation simply ratio the thermal with the electric output. For less than 50% electric power output, the ratio of thermal output to electrical output will increase. However, a 480007-001 Rev D (June 2005) Page 13 of 21 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the equipment ratings, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Correction FactorPDF Image | Application Guide - Model C60 Integrated CHP (ICHP)

PDF Search Title:

Application Guide - Model C60 Integrated CHP (ICHP)Original File Name Searched:

480007_ICHP_AppGuide.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |