PDF Publication Title:

Text from PDF Page: 012

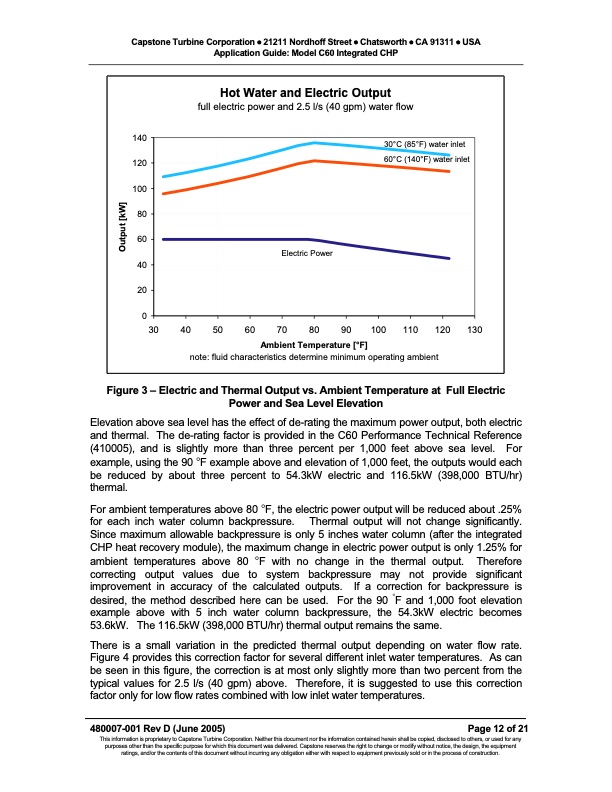

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: Model C60 Integrated CHP 140 120 100 80 60 40 20 Hot Water and Electric Output full electric power and 2.5 l/s (40 gpm) water flow Electric Power 30°C (85°F) water inlet 60°C (140°F) water inlet 0 30 40 50 60 70 80 90 100 110 120 130 Ambient Temperature [°F] note: fluid characteristics determine minimum operating ambient Figure 3 – Electric and Thermal Output vs. Ambient Temperature at Full Electric Power and Sea Level Elevation Elevation above sea level has the effect of de-rating the maximum power output, both electric and thermal. The de-rating factor is provided in the C60 Performance Technical Reference (410005), and is slightly more than three percent per 1,000 feet above sea level. For example, using the 90 °F example above and elevation of 1,000 feet, the outputs would each be reduced by about three percent to 54.3kW electric and 116.5kW (398,000 BTU/hr) thermal. For ambient temperatures above 80 °F, the electric power output will be reduced about .25% for each inch water column backpressure. Thermal output will not change significantly. Since maximum allowable backpressure is only 5 inches water column (after the integrated CHP heat recovery module), the maximum change in electric power output is only 1.25% for ambient temperatures above 80 °F with no change in the thermal output. Therefore correcting output values due to system backpressure may not provide significant improvement in accuracy of the calculated outputs. If a correction for backpressure is desired, the method described here can be used. For the 90 °F and 1,000 foot elevation example above with 5 inch water column backpressure, the 54.3kW electric becomes 53.6kW. The 116.5kW (398,000 BTU/hr) thermal output remains the same. There is a small variation in the predicted thermal output depending on water flow rate. Figure 4 provides this correction factor for several different inlet water temperatures. As can be seen in this figure, the correction is at most only slightly more than two percent from the typical values for 2.5 l/s (40 gpm) above. Therefore, it is suggested to use this correction factor only for low flow rates combined with low inlet water temperatures. 480007-001 Rev D (June 2005) Page 12 of 21 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the equipment ratings, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Output [kW]PDF Image | Application Guide - Model C60 Integrated CHP (ICHP)

PDF Search Title:

Application Guide - Model C60 Integrated CHP (ICHP)Original File Name Searched:

480007_ICHP_AppGuide.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |