PDF Publication Title:

Text from PDF Page: 007

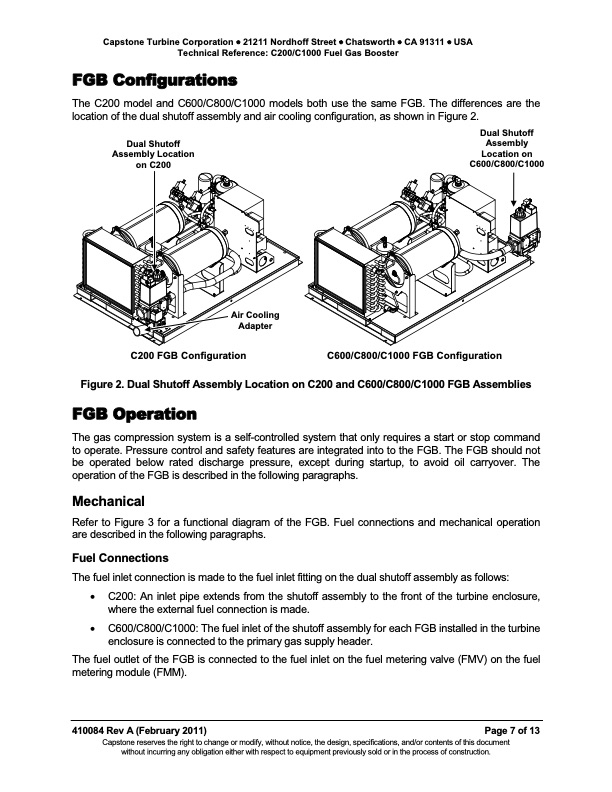

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: C200/C1000 Fuel Gas Booster FGB Configurations The C200 model and C600/C800/C1000 models both use the same FGB. The differences are the location of the dual shutoff assembly and air cooling configuration, as shown in Figure 2. Dual Shutoff Assembly Location on C200 Dual Shutoff Assembly Location on C600/C800/C1000 Air Cooling Adapter C200 FGB Configuration C600/C800/C1000 FGB Configuration Figure 2. Dual Shutoff Assembly Location on C200 and C600/C800/C1000 FGB Assemblies FGB Operation The gas compression system is a self-controlled system that only requires a start or stop command to operate. Pressure control and safety features are integrated into to the FGB. The FGB should not be operated below rated discharge pressure, except during startup, to avoid oil carryover. The operation of the FGB is described in the following paragraphs. Mechanical Refer to Figure 3 for a functional diagram of the FGB. Fuel connections and mechanical operation are described in the following paragraphs. Fuel Connections The fuel inlet connection is made to the fuel inlet fitting on the dual shutoff assembly as follows: • C200: An inlet pipe extends from the shutoff assembly to the front of the turbine enclosure, where the external fuel connection is made. • C600/C800/C1000: The fuel inlet of the shutoff assembly for each FGB installed in the turbine enclosure is connected to the primary gas supply header. The fuel outlet of the FGB is connected to the fuel inlet on the fuel metering valve (FMV) on the fuel metering module (FMM). 410084 Rev A (February 2011) Page 7 of 13 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference C200/C1000 Fuel Gas Booster (FGB)

PDF Search Title:

Technical Reference C200/C1000 Fuel Gas Booster (FGB)Original File Name Searched:

410084_C200_C1000_FGB_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |