PDF Publication Title:

Text from PDF Page: 038

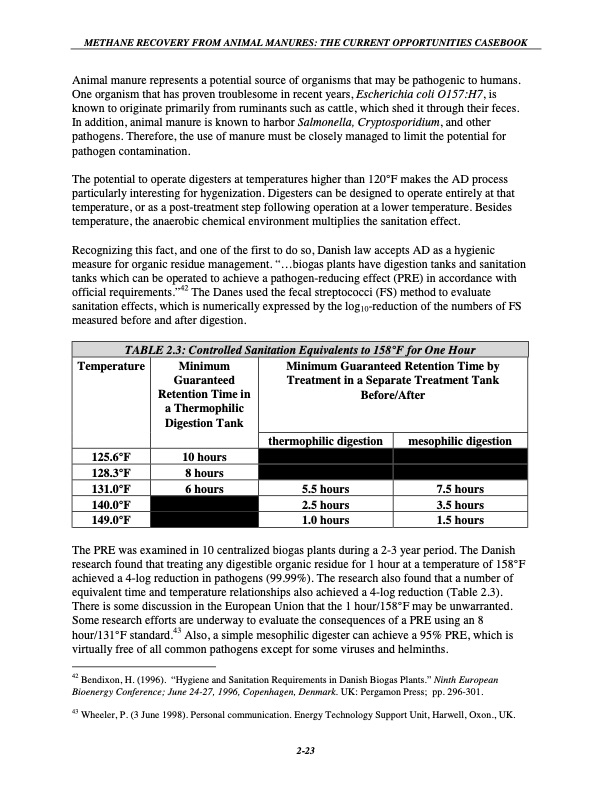

METHANE RECOVERY FROM ANIMAL MANURES: THE CURRENT OPPORTUNITIES CASEBOOK Animal manure represents a potential source of organisms that may be pathogenic to humans. One organism that has proven troublesome in recent years, Escherichia coli O157:H7, is known to originate primarily from ruminants such as cattle, which shed it through their feces. In addition, animal manure is known to harbor Salmonella, Cryptosporidium, and other pathogens. Therefore, the use of manure must be closely managed to limit the potential for pathogen contamination. The potential to operate digesters at temperatures higher than 120°F makes the AD process particularly interesting for hygenization. Digesters can be designed to operate entirely at that temperature, or as a post-treatment step following operation at a lower temperature. Besides temperature, the anaerobic chemical environment multiplies the sanitation effect. Recognizing this fact, and one of the first to do so, Danish law accepts AD as a hygienic measure for organic residue management. “...biogas plants have digestion tanks and sanitation tanks which can be operated to achieve a pathogen-reducing effect (PRE) in accordance with 42 official requirements.” The Danes used the fecal streptococci (FS) method to evaluate sanitation effects, which is numerically expressed by the log10-reduction of the numbers of FS measured before and after digestion. TABLE 2.3: Controlled Sanitation Equivalents to 158°F for One Hour Minimum Guaranteed Retention Time by Treatment in a Separate Treatment Tank Before/After Temperature 125.6°F 128.3°F 131.0°F 140.0°F 149.0°F Minimum Guaranteed Retention Time in a Thermophilic Digestion Tank 10 hours 8 hours 6 hours thermophilic digestion 5.5 hours 2.5 hours 1.0 hours mesophilic digestion 7.5 hours 3.5 hours 1.5 hours The PRE was examined in 10 centralized biogas plants during a 2-3 year period. The Danish research found that treating any digestible organic residue for 1 hour at a temperature of 158°F achieved a 4-log reduction in pathogens (99.99%). The research also found that a number of equivalent time and temperature relationships also achieved a 4-log reduction (Table 2.3). There is some discussion in the European Union that the 1 hour/158°F may be unwarranted. Some research efforts are underway to evaluate the consequences of a PRE using an 8 43 hour/131°F standard. Also, a simple mesophilic digester can achieve a 95% PRE, which is virtually free of all common pathogens except for some viruses and helminths. 42 Bioenergy Conference; June 24-27, 1996, Copenhagen, Denmark. UK: Pergamon Press; pp. 296-301. 43 Wheeler, P. (3 June 1998). Personal communication. Energy Technology Support Unit, Harwell, Oxon., UK. Bendixon, H. (1996). “Hygiene and Sanitation Requirements in Danish Biogas Plants.” Ninth European 2-23PDF Image | Methane Recovery from Animal Manures The Current Opportunities Casebook

PDF Search Title:

Methane Recovery from Animal Manures The Current Opportunities CasebookOriginal File Name Searched:

biogas02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |