PDF Publication Title:

Text from PDF Page: 019

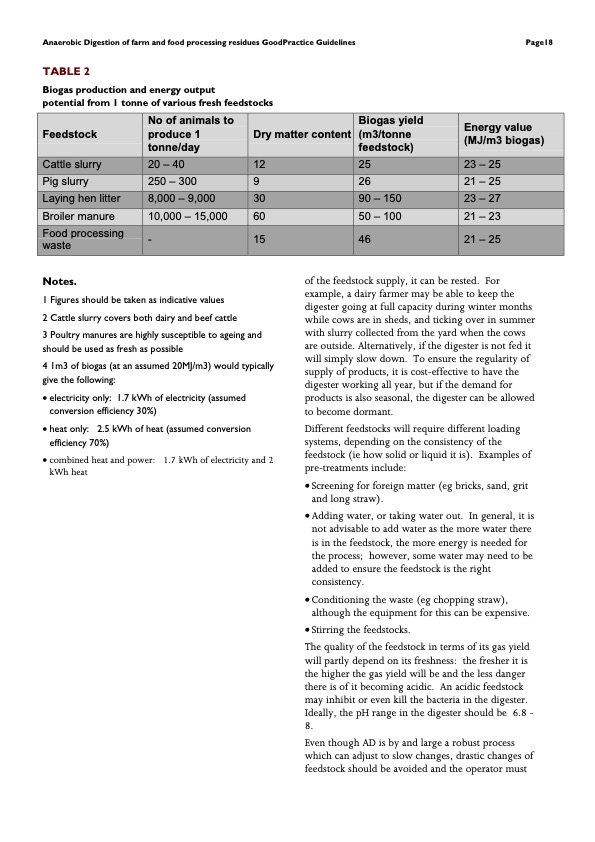

Anaerobic Digestion of farm and food processing residues GoodPractice Guidelines Page18 TABLE 2 Biogas production and energy output potential from 1 tonne of various fresh feedstocks Feedstock No of animals to produce 1 tonne/day Dry matter content Biogas yield (m3/tonne feedstock) Energy value (MJ/m3 biogas) Cattle slurry 20 – 40 12 25 23 – 25 Pig slurry 250 – 300 9 26 21 – 25 Laying hen litter 8,000 – 9,000 30 90 – 150 23 – 27 Broiler manure 10,000 – 15,000 60 50 – 100 21 – 23 Food processing waste - 15 46 21 – 25 Notes. 1 Figures should be taken as indicative values 2 Cattle slurry covers both dairy and beef cattle 3 Poultry manures are highly susceptible to ageing and should be used as fresh as possible 4 1m3 of biogas (at an assumed 20MJ/m3) would typically give the following: • electricity only: 1.7 kWh of electricity (assumed conversion efficiency 30%) • heat only: 2.5 kWh of heat (assumed conversion efficiency 70%) of the feedstock supply, it can be rested. For example, a dairy farmer may be able to keep the digester going at full capacity during winter months while cows are in sheds, and ticking over in summer with slurry collected from the yard when the cows are outside. Alternatively, if the digester is not fed it will simply slow down. To ensure the regularity of supply of products, it is cost-effective to have the digester working all year, but if the demand for products is also seasonal, the digester can be allowed to become dormant. Different feedstocks will require different loading systems, depending on the consistency of the feedstock (ie how solid or liquid it is). Examples of pre-treatments include: • Screening for foreign matter (eg bricks, sand, grit and long straw). • Adding water, or taking water out. In general, it is not advisable to add water as the more water there is in the feedstock, the more energy is needed for the process; however, some water may need to be added to ensure the feedstock is the right consistency. • Conditioning the waste (eg chopping straw), although the equipment for this can be expensive. • Stirring the feedstocks. The quality of the feedstock in terms of its gas yield will partly depend on its freshness: the fresher it is the higher the gas yield will be and the less danger there is of it becoming acidic. An acidic feedstock may inhibit or even kill the bacteria in the digester. Ideally, the pH range in the digester should be 6.8 - 8. Even though AD is by and large a robust process which can adjust to slow changes, drastic changes of feedstock should be avoided and the operator must • combined heat and power: kWh heat 1.7 kWh of electricity and 2PDF Image | Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industry

PDF Search Title:

Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industryOriginal File Name Searched:

biogas10.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |