PDF Publication Title:

Text from PDF Page: 002

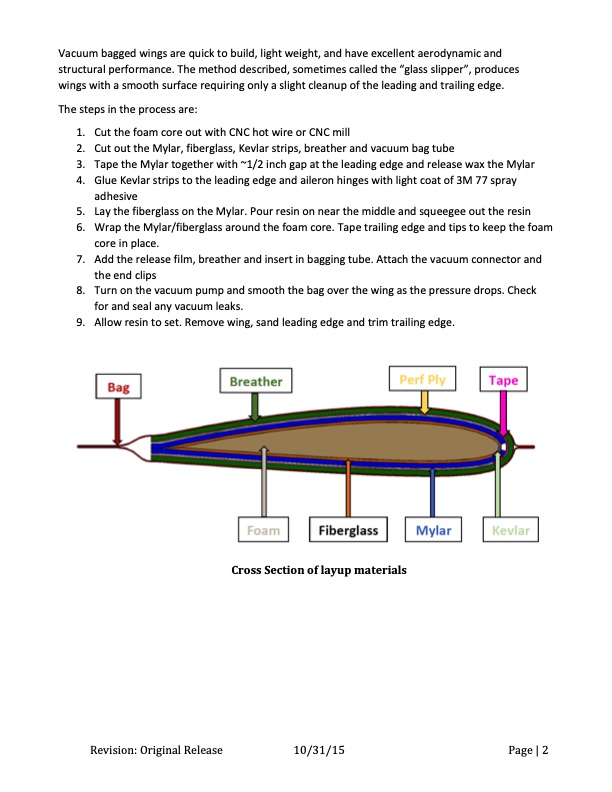

Vacuum bagged wings are quick to build, light weight, and have excellent aerodynamic and structural performance. The method described, sometimes called the “glass slipper”, produces wings with a smooth surface requiring only a slight cleanup of the leading and trailing edge. The steps in the process are: 1. Cut the foam core out with CNC hot wire or CNC mill 2. Cut out the Mylar, fiberglass, Kevlar strips, breather and vacuum bag tube 3. Tape the Mylar together with ~1/2 inch gap at the leading edge and release wax the Mylar 4. Glue Kevlar strips to the leading edge and aileron hinges with light coat of 3M 77 spray adhesive 5. Lay the fiberglass on the Mylar. Pour resin on near the middle and squeegee out the resin 6. Wrap the Mylar/fiberglass around the foam core. Tape trailing edge and tips to keep the foam core in place. 7. Add the release film, breather and insert in bagging tube. Attach the vacuum connector and the end clips 8. Turn on the vacuum pump and smooth the bag over the wing as the pressure drops. Check for and seal any vacuum leaks. 9. Allow resin to set. Remove wing, sand leading edge and trim trailing edge. Cross Section of layup materials Revision: Original Release 10/31/15 Page | 2PDF Image | Vacuum Bagging Wings Instruction Manual Purdue Univ

PDF Search Title:

Vacuum Bagging Wings Instruction Manual Purdue UnivOriginal File Name Searched:

Vacuum-Bagging-Instruction-Manual.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |