PDF Publication Title:

Text from PDF Page: 053

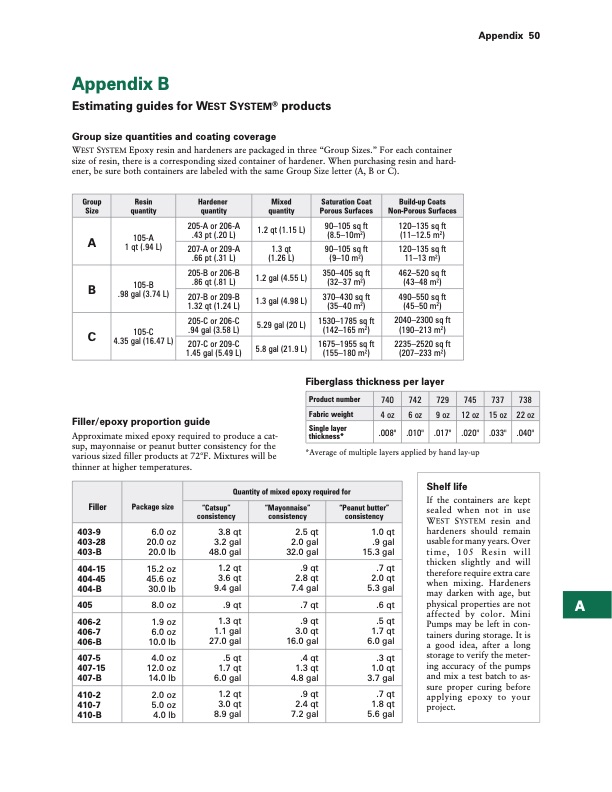

Appendix B Estimating guides for WEST SYSTEM® products Group size quantities and coating coverage WEST SYSTEM Epoxy resin and hardeners are packaged in three “Group Sizes.” For each container size of resin, there is a corresponding sized container of hardener. When purchasing resin and hard- ener, be sure both containers are labeled with the same Group Size letter (A, B or C). Appendix 50 Group Size Resin quantity Hardener quantity Mixed quantity Saturation Coat Porous Surfaces Build-up Coats Non-Porous Surfaces A 105-A 1 qt (.94 L) 205-A or 206-A .43 pt (.20 L) 1.2 qt (1.15 L) 90–105 sq ft (8.5–10m2) 120–135 sq ft (11–12.5 m2) 207-A or 209-A .66 pt (.31 L) 1.3 qt (1.26 L) 90–105 sq ft (9–10 m2) 120–135 sq ft 11–13 m2) B 105-B .98 gal (3.74 L) 205-B or 206-B .86 qt (.81 L) 1.2 gal (4.55 L) 350–405 sq ft (32–37 m2) 462–520 sq ft (43–48 m2) 207-B or 209-B 1.32 qt (1.24 L) 1.3 gal (4.98 L) 370–430 sq ft (35–40 m2) 490–550 sq ft (45–50 m2) C 105-C 4.35 gal (16.47 L) 205-C or 206-C .94 gal (3.58 L) 5.29 gal (20 L) 1530–1785 sq ft (142–165 m2) 2040–2300 sq ft (190–213 m2) 207-C or 209-C 1.45 gal (5.49 L) 5.8 gal (21.9 L) 1675–1955 sq ft (155–180 m2) 2235–2520 sq ft (207–233 m2) Product number 740 742 729 745 737 738 Fabric weight 4 oz 6 oz 9 oz 12 oz 15 oz 22 oz Single layer thickness* .008" .010" .017" .020" .033" .040" Filler/epoxy proportion guide Approximate mixed epoxy required to produce a cat- sup, mayonnaise or peanut butter consistency for the various sized filler products at 72°F. Mixtures will be thinner at higher temperatures. Fiberglass thickness per layer *Average of multiple layers applied by hand lay-up Shelf life If the containers are kept sealed when not in use WEST SYSTEM resin and hardeners should remain usable for many years. Over time, 105 Resin will thicken slightly and will therefore require extra care when mixing. Hardeners may darken with age, but physical properties are not affected by color. Mini Pumps may be left in con- tainers during storage. It is a good idea, after a long storage to verify the meter- ing accuracy of the pumps and mix a test batch to as- sure proper curing before applying epoxy to your project. Filler Package size Quantity of mixed epoxy required for “Catsup” consistency “Mayonnaise” consistency “Peanut butter” consistency 403-9 403-28 403-B 6.0 oz 20.0 oz 20.0 lb 3.8 qt 3.2 gal 48.0 gal 2.5 qt 2.0 gal 32.0 gal 1.0 qt .9 gal 15.3 gal 404-15 404-45 404-B 15.2 oz 45.6 oz 30.0 lb 1.2 qt 3.6 qt 9.4 gal .9 qt 2.8 qt 7.4 gal .7 qt 2.0 qt 5.3 gal 405 8.0 oz .9 qt .7 qt .6 qt 406-2 406-7 406-B 1.9 oz 6.0 oz 10.0 lb 1.3 qt 1.1 gal 27.0 gal .9 qt 3.0 qt 16.0 gal .5 qt 1.7 qt 6.0 gal 407-5 407-15 407-B 4.0 oz 12.0 oz 14.0 lb .5 qt 1.7 qt 6.0 gal .4 qt 1.3 qt 4.8 gal .3 qt 1.0 qt 3.7 gal 410-2 410-7 410-B 2.0 oz 5.0 oz 4.0 lb 1.2 qt 3.0 qt 8.9 gal .9 qt 2.4 qt 7.2 gal .7 qt 1.8 qt 5.6 gal APDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |