PDF Publication Title:

Text from PDF Page: 052

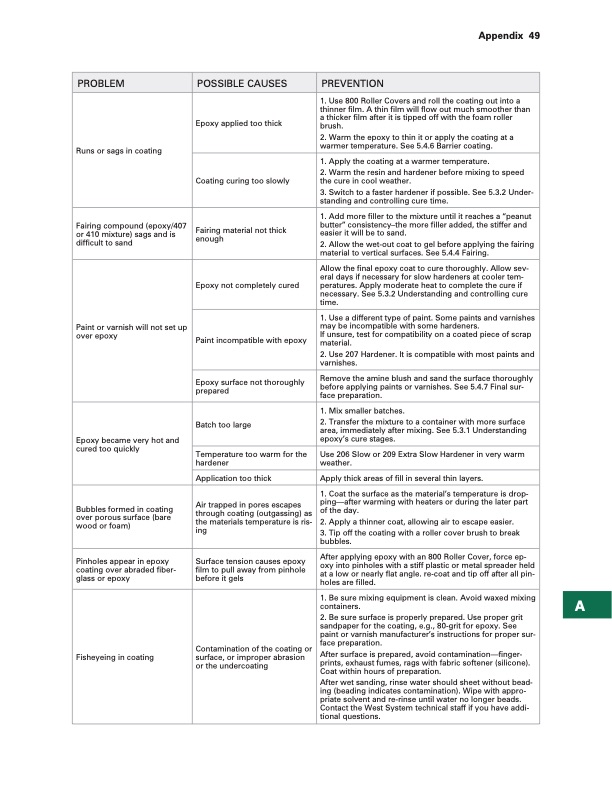

Appendix 49 PROBLEM POSSIBLE CAUSES PREVENTION Runs or sags in coating Epoxy applied too thick 1. Use 800 Roller Covers and roll the coating out into a thinner film. A thin film will flow out much smoother than a thicker film after it is tipped off with the foam roller brush. 2. Warm the epoxy to thin it or apply the coating at a warmer temperature. See 5.4.6 Barrier coating. Coating curing too slowly 1. Apply the coating at a warmer temperature. 2. Warm the resin and hardener before mixing to speed the cure in cool weather. 3. Switch to a faster hardener if possible. See 5.3.2 Under- standing and controlling cure time. Fairing compound (epoxy/407 or 410 mixture) sags and is difficult to sand Fairing material not thick enough 1. Add more filler to the mixture until it reaches a “peanut butter” consistency–the more filler added, the stiffer and easier it will be to sand. 2. Allow the wet-out coat to gel before applying the fairing material to vertical surfaces. See 5.4.4 Fairing. Paint or varnish will not set up over epoxy Epoxy not completely cured Allow the final epoxy coat to cure thoroughly. Allow sev- eral days if necessary for slow hardeners at cooler tem- peratures. Apply moderate heat to complete the cure if necessary. See 5.3.2 Understanding and controlling cure time. Paint incompatible with epoxy 1. Use a different type of paint. Some paints and varnishes may be incompatible with some hardeners. If unsure, test for compatibility on a coated piece of scrap material. 2. Use 207 Hardener. It is compatible with most paints and varnishes. Epoxy surface not thoroughly prepared Remove the amine blush and sand the surface thoroughly before applying paints or varnishes. See 5.4.7 Final sur- face preparation. Epoxy became very hot and cured too quickly Batch too large 1. Mix smaller batches. 2. Transfer the mixture to a container with more surface area, immediately after mixing. See 5.3.1 Understanding epoxy’s cure stages. Temperature too warm for the hardener Use 206 Slow or 209 Extra Slow Hardener in very warm weather. Application too thick Apply thick areas of fill in several thin layers. Bubbles formed in coating over porous surface (bare wood or foam) Air trapped in pores escapes through coating (outgassing) as the materials temperature is ris- ing 1. Coat the surface as the material’s temperature is drop- ping—after warming with heaters or during the later part of the day. 2. Apply a thinner coat, allowing air to escape easier. 3. Tip off the coating with a roller cover brush to break bubbles. Pinholes appear in epoxy coating over abraded fiber- glass or epoxy Surface tension causes epoxy film to pull away from pinhole before it gels After applying epoxy with an 800 Roller Cover, force ep- oxy into pinholes with a stiff plastic or metal spreader held at a low or nearly flat angle. re-coat and tip off after all pin- holes are filled. Fisheyeing in coating Contamination of the coating or surface, or improper abrasion or the undercoating 1. Be sure mixing equipment is clean. Avoid waxed mixing containers. 2. Be sure surface is properly prepared. Use proper grit sandpaper for the coating, e.g., 80-grit for epoxy. See paint or varnish manufacturer’s instructions for proper sur- face preparation. After surface is prepared, avoid contamination—finger- prints, exhaust fumes, rags with fabric softener (silicone). Coat within hours of preparation. After wet sanding, rinse water should sheet without bead- ing (beading indicates contamination). Wipe with appro- priate solvent and re-rinse until water no longer beads. Contact the West System technical staff if you have addi- tional questions. APDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |