PDF Publication Title:

Text from PDF Page: 036

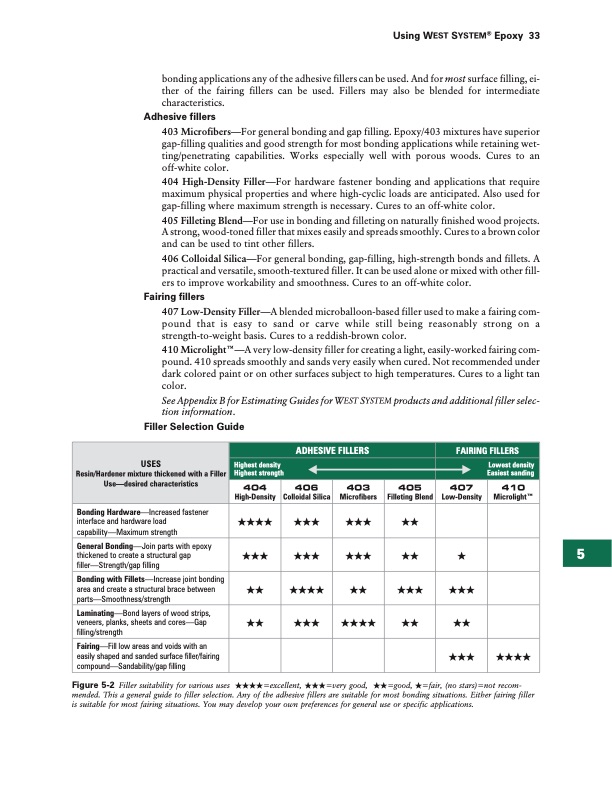

bonding applications any of the adhesive fillers can be used. And for most surface filling, ei- ther of the fairing fillers can be used. Fillers may also be blended for intermediate characteristics. Adhesive fillers 403 Microfibers—For general bonding and gap filling. Epoxy/403 mixtures have superior gap-filling qualities and good strength for most bonding applications while retaining wet- ting/penetrating capabilities. Works especially well with porous woods. Cures to an off-white color. 404 High-Density Filler—For hardware fastener bonding and applications that require maximum physical properties and where high-cyclic loads are anticipated. Also used for gap-filling where maximum strength is necessary. Cures to an off-white color. 405 Filleting Blend—For use in bonding and filleting on naturally finished wood projects. A strong, wood-toned filler that mixes easily and spreads smoothly. Cures to a brown color and can be used to tint other fillers. 406 Colloidal Silica—For general bonding, gap-filling, high-strength bonds and fillets. A practical and versatile, smooth-textured filler. It can be used alone or mixed with other fill- ers to improve workability and smoothness. Cures to an off-white color. Fairing fillers 407 Low-Density Filler—A blended microballoon-based filler used to make a fairing com- pound that is easy to sand or carve while still being reasonably strong on a strength-to-weight basis. Cures to a reddish-brown color. 410 MicrolightTM—A very low-density filler for creating a light, easily-worked fairing com- pound. 410 spreads smoothly and sands very easily when cured. Not recommended under dark colored paint or on other surfaces subject to high temperatures. Cures to a light tan color. See Appendix B for Estimating Guides for WEST SYSTEM products and additional filler selec- tion information. Filler Selection Guide Using WEST SYSTEM® Epoxy 33 USES Resin/Hardener mixture thickened with a Filler Use—desired characteristics ADHESIVE FILLERS FAIRING FILLERS Highest density Highest strength Lowest density Easiest sanding 404 High-Density 406 Colloidal Silica 403 Microfibers 405 Filleting Blend 407 Low-Density 410 MicrolightTM Bonding Hardware—Increased fastener interface and hardware load capability—Maximum strength rrrr rrr rrr rr General Bonding—Join parts with epoxy thickened to create a structural gap filler—Strength/gap filling rrr rrr rrr rr r Bonding with Fillets—Increase joint bonding area and create a structural brace between parts—Smoothness/strength rr rrrr rr rrr rrr Laminating—Bond layers of wood strips, veneers, planks, sheets and cores—Gap filling/strength rr rrr rrrr rr rr Fairing—Fill low areas and voids with an easily shaped and sanded surface filler/fairing compound—Sandability/gap filling rrr rrrr Figure 5-2 Filler suitability for various uses rrrr=excellent, rrr=very good, rr=good, r=fair, (no stars)=not recom- mended. This a general guide to filler selection. Any of the adhesive fillers are suitable for most bonding situations. Either fairing filler is suitable for most fairing situations. You may develop your own preferences for general use or specific applications. 5PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |