PDF Publication Title:

Text from PDF Page: 035

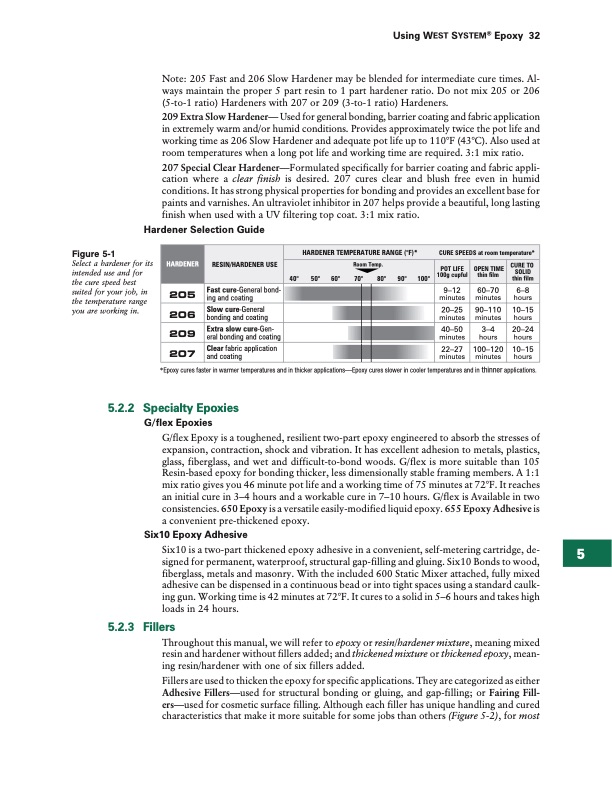

Figure 5-1 Select a hardener for its intended use and for the cure speed best suited for your job, in the temperature range you are working in. Note: 205 Fast and 206 Slow Hardener may be blended for intermediate cure times. Al- ways maintain the proper 5 part resin to 1 part hardener ratio. Do not mix 205 or 206 (5-to-1 ratio) Hardeners with 207 or 209 (3-to-1 ratio) Hardeners. 209 Extra Slow Hardener— Used for general bonding, barrier coating and fabric application in extremely warm and/or humid conditions. Provides approximately twice the pot life and working time as 206 Slow Hardener and adequate pot life up to 110°F (43°C). Also used at room temperatures when a long pot life and working time are required. 3:1 mix ratio. 207 Special Clear Hardener—Formulated specifically for barrier coating and fabric appli- cation where a clear finish is desired. 207 cures clear and blush free even in humid conditions. It has strong physical properties for bonding and provides an excellent base for paints and varnishes. An ultraviolet inhibitor in 207 helps provide a beautiful, long lasting finish when used with a UV filtering top coat. 3:1 mix ratio. Hardener Selection Guide Using WEST SYSTEM® Epoxy 32 HARDENER RESIN/HARDENER USE HARDENER TEMPERATURE RANGE (°F)* CURE SPEEDS at room temperature* Room Temp. 40° 50° 60° 70° 80° 90° 100° POT LIFE 100g cupful OPEN TIME thin film CURE TO SOLID thin film 205 Fast cure-General bond- ing and coating 9–12 minutes 60–70 minutes 6–8 hours 206 Slow cure-General bonding and coating 20–25 minutes 90–110 minutes 10–15 hours 209 Extra slow cure-Gen- eral bonding and coating 40–50 minutes 3–4 hours 20–24 hours 207 Clear fabric application and coating 22–27 minutes 100–120 minutes 10–15 hours *Epoxy cures faster in warmer temperatures and in thicker applications—Epoxy cures slower in cooler temperatures and in thinner applications. 5.2.2 Specialty Epoxies G/flex Epoxies G/flex Epoxy is a toughened, resilient two-part epoxy engineered to absorb the stresses of expansion, contraction, shock and vibration. It has excellent adhesion to metals, plastics, glass, fiberglass, and wet and difficult-to-bond woods. G/flex is more suitable than 105 Resin-based epoxy for bonding thicker, less dimensionally stable framing members. A 1:1 mix ratio gives you 46 minute pot life and a working time of 75 minutes at 72°F. It reaches an initial cure in 3–4 hours and a workable cure in 7–10 hours. G/flex is Available in two consistencies. 650 Epoxy is a versatile easily-modified liquid epoxy. 655 Epoxy Adhesive is a convenient pre-thickened epoxy. Six10 Epoxy Adhesive Six10 is a two-part thickened epoxy adhesive in a convenient, self-metering cartridge, de- signed for permanent, waterproof, structural gap-filling and gluing. Six10 Bonds to wood, fiberglass, metals and masonry. With the included 600 Static Mixer attached, fully mixed adhesive can be dispensed in a continuous bead or into tight spaces using a standard caulk- ing gun. Working time is 42 minutes at 72°F. It cures to a solid in 5–6 hours and takes high loads in 24 hours. 5.2.3 Fillers Throughout this manual, we will refer to epoxy or resin/hardener mixture, meaning mixed resin and hardener without fillers added; and thickened mixture or thickened epoxy, mean- ing resin/hardener with one of six fillers added. Fillers are used to thicken the epoxy for specific applications. They are categorized as either Adhesive Fillers—used for structural bonding or gluing, and gap-filling; or Fairing Fill- ers—used for cosmetic surface filling. Although each filler has unique handling and cured characteristics that make it more suitable for some jobs than others (Figure 5-2), for most 5PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |