PDF Publication Title:

Text from PDF Page: 021

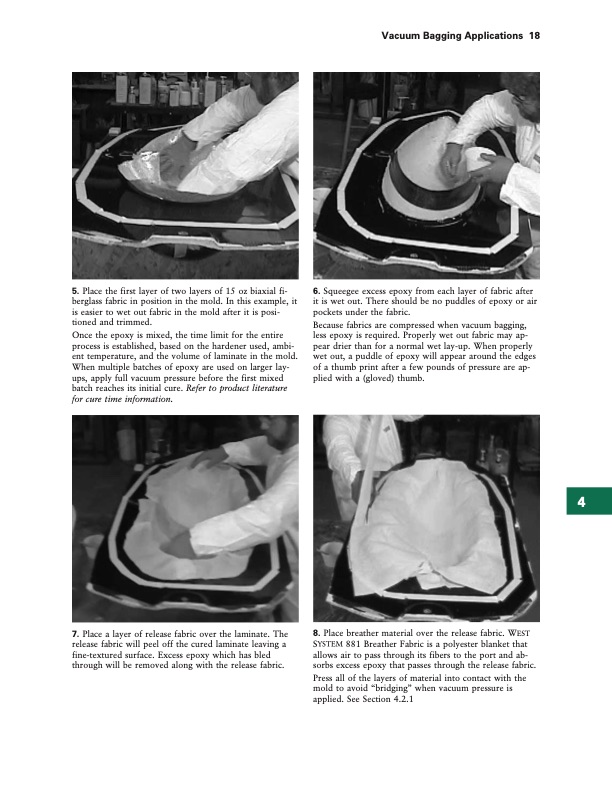

Vacuum Bagging Applications 18 5. Place the first layer of two layers of 15 oz biaxial fi- berglass fabric in position in the mold. In this example, it is easier to wet out fabric in the mold after it is posi- tioned and trimmed. Once the epoxy is mixed, the time limit for the entire process is established, based on the hardener used, ambi- ent temperature, and the volume of laminate in the mold. When multiple batches of epoxy are used on larger lay- ups, apply full vacuum pressure before the first mixed batch reaches its initial cure. Refer to product literature for cure time information. 7. Place a layer of release fabric over the laminate. The release fabric will peel off the cured laminate leaving a fine-textured surface. Excess epoxy which has bled through will be removed along with the release fabric. 6. Squeegee excess epoxy from each layer of fabric after it is wet out. There should be no puddles of epoxy or air pockets under the fabric. Because fabrics are compressed when vacuum bagging, less epoxy is required. Properly wet out fabric may ap- pear drier than for a normal wet lay-up. When properly wet out, a puddle of epoxy will appear around the edges of a thumb print after a few pounds of pressure are ap- plied with a (gloved) thumb. 8. Place breather material over the release fabric. WEST SYSTEM 881 Breather Fabric is a polyester blanket that allows air to pass through its fibers to the port and ab- sorbs excess epoxy that passes through the release fabric. Press all of the layers of material into contact with the mold to avoid “bridging” when vacuum pressure is applied. See Section 4.2.1 4PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |