PDF Publication Title:

Text from PDF Page: 020

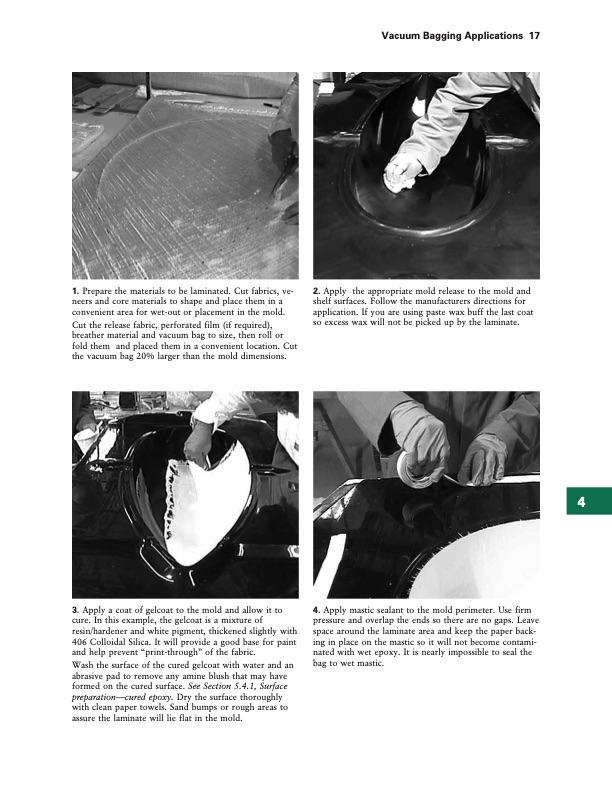

1. Prepare the materials to be laminated. Cut fabrics, ve- neers and core materials to shape and place them in a convenient area for wet-out or placement in the mold. Cut the release fabric, perforated film (if required), breather material and vacuum bag to size, then roll or fold them and placed them in a convenient location. Cut the vacuum bag 20% larger than the mold dimensions. 3. Apply a coat of gelcoat to the mold and allow it to cure. In this example, the gelcoat is a mixture of resin/hardener and white pigment, thickened slightly with 406 Colloidal Silica. It will provide a good base for paint and help prevent “print-through” of the fabric. Wash the surface of the cured gelcoat with water and an abrasive pad to remove any amine blush that may have formed on the cured surface. See Section 5.4.1, Surface preparation—cured epoxy. Dry the surface thoroughly with clean paper towels. Sand bumps or rough areas to assure the laminate will lie flat in the mold. 2. Apply the appropriate mold release to the mold and shelf surfaces. Follow the manufacturers directions for application. If you are using paste wax buff the last coat so excess wax will not be picked up by the laminate. 4. Apply mastic sealant to the mold perimeter. Use firm pressure and overlap the ends so there are no gaps. Leave space around the laminate area and keep the paper back- ing in place on the mastic so it will not become contami- nated with wet epoxy. It is nearly impossible to seal the bag to wet mastic. Vacuum Bagging Applications 17 4PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |