PDF Publication Title:

Text from PDF Page: 002

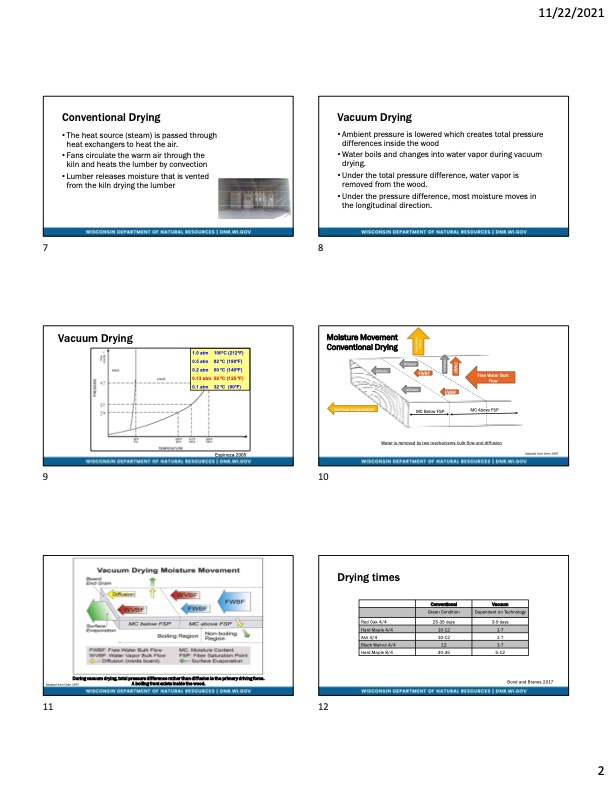

11/22/2021 Conventional Drying • The heat source (steam) is passed through heat exchangers to heat the air. • Fans circulate the warm air through the kiln and heats the lumber by convection • Lumber releases moisture that is vented from the kiln drying the lumber Vacuum Drying • Ambient pressure is lowered which creates total pressure differences inside the wood • Water boils and changes into water vapor during vacuum drying. • Under the total pressure difference, water vapor is removed from the wood. • Under the pressure difference, most moisture moves in the longitudinal direction. 78 9 10 11 12 Vacuum Drying 1.0 atm 0.5 atm 0.2 atm 0.13 atm 52 oC (125 oF) 0.1 atm 32 oC (90oF) 100oC (212oF) 82 oC (180oF) 60 oC (140oF) Espinoza 2005 Moisture Movement Conventional Drying Diffusion Diffusion FWBF Diffusion MC Below FSP Free Water Bulk Flow MC Above FSP Surface Evaporation Water is removed by two mechanisms bulk flow and diffusion FWBF Adapted from Chen 1997 During vacuum drying, total pressure difference rather than diffusion is the primary driving force. Adapted from Chen 1997 A boiling front exists inside the wood. Drying times Conventional Vacuum Green Condition Dependent on Technology Red Oak 4/4 25-35 days 3-9 days Hard Maple 4/4 10-12 1-7 Ash 4/4 10-12 1-7 Black Walnut 4/4 12 1-7 Hard Maple 8/4 30-35 5-12 Bond and Brenes 2017 2 Surface Evaporation FWBF DiffusionPDF Image | Understanding Vacuum Drying Technologies

PDF Search Title:

Understanding Vacuum Drying TechnologiesOriginal File Name Searched:

DryKiln_Session4_ScottLyon.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |