PDF Publication Title:

Text from PDF Page: 005

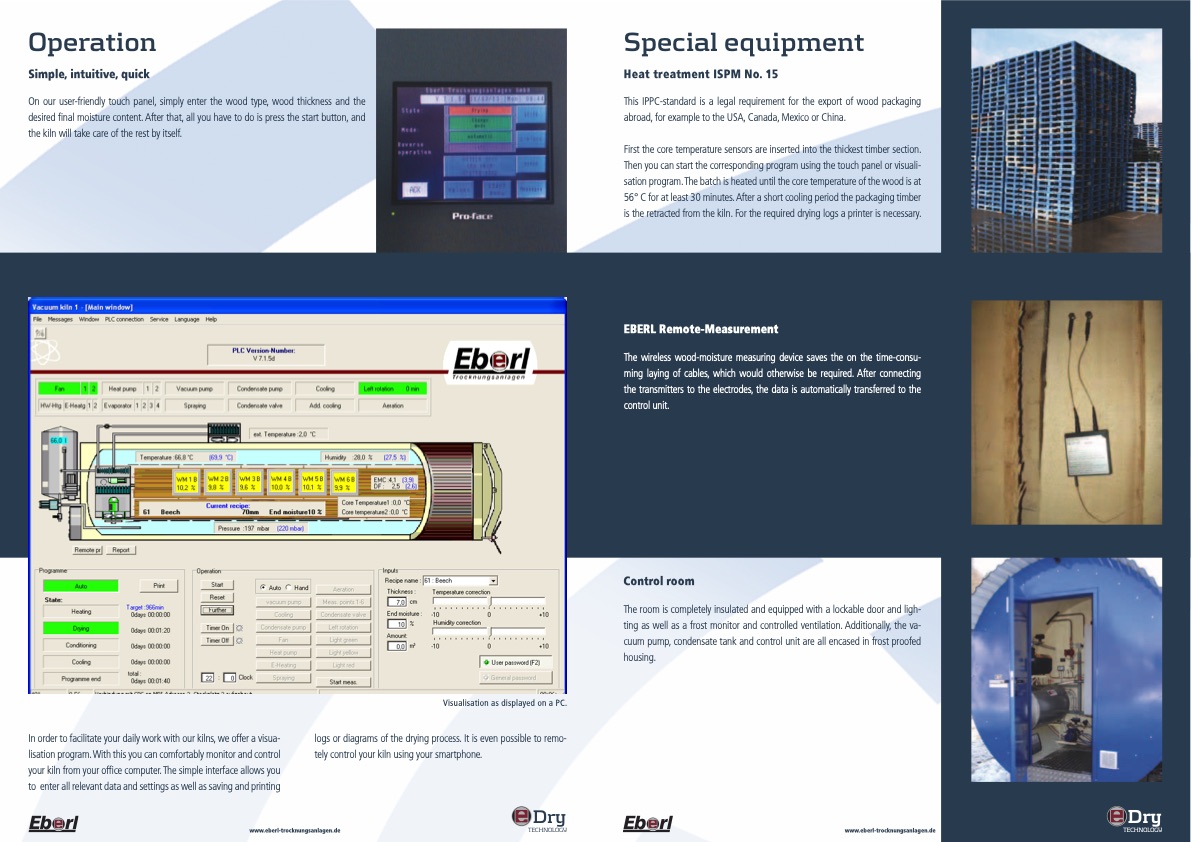

Operation Simple, intuitive, quick On our user-friendly touch panel, simply enter the wood type, wood thickness and the desired final moisture content. After that, all you have to do is press the start button, and the kiln will take care of the rest by itself. Special equipment Heat treatment ISPM No. 15 This IPPC-standard is a legal requirement for the export of wood packaging abroad, for example to the USA, Canada, Mexico or China. First the core temperature sensors are inserted into the thickest timber section. Then you can start the corresponding program using the touch panel or visuali- sation program. The batch is heated until the core temperature of the wood is at 56° C for at least 30 minutes. After a short cooling period the packaging timber is the retracted from the kiln. For the required drying logs a printer is necessary. EBERL Dry TECHNOLOGY EBERL Remote-Measurement The wireless wood-moisture measuring device saves the on the time-consu- ming laying of cables, which would otherwise be required. After connecting the transmitters to the electrodes, the data is automatically transferred to the control unit. In order to facilitate your daily work with our kilns, we offer a visua- lisation program. With this you can comfortably monitor and control your kiln from your office computer. The simple interface allows you to enter all relevant data and settings as well as saving and printing Visualisation as displayed on a PC. logs or diagrams of the drying process. It is even possible to remo- tely control your kiln using your smartphone. Control room The room is completely insulated and equipped with a lockable door and ligh- ting as well as a frost monitor and controlled ventilation. Additionally, the va- cuum pump, condensate tank and control unit are all encased in frost proofed housing. EBERL Dry www.eberl-trocknungsanlagen.de TECHNOLOGY www.eberl-trocknungsanlagen.dePDF Image | The vacuum dry kiln

PDF Search Title:

The vacuum dry kilnOriginal File Name Searched:

ebe_vbasic_vcomfort_vpremium_2013_en.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |