PDF Publication Title:

Text from PDF Page: 004

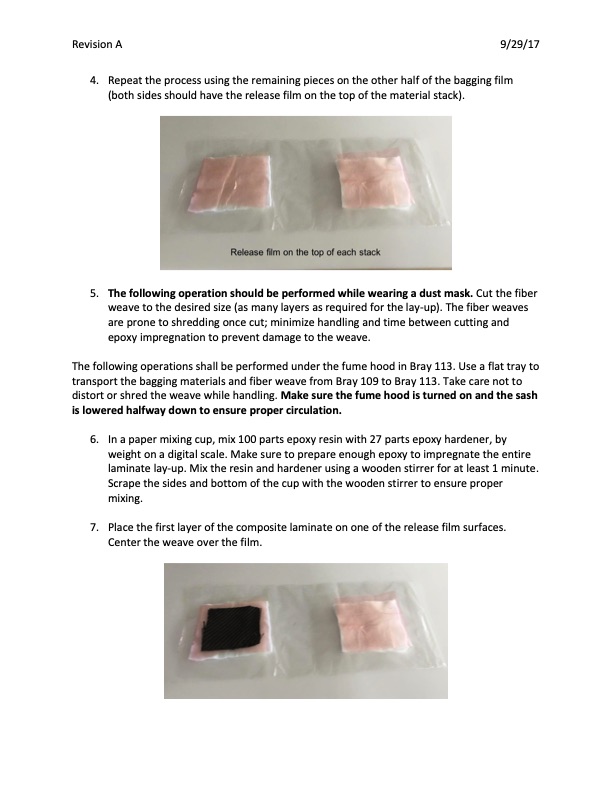

Revision A 9/29/17 4. Repeat the process using the remaining pieces on the other half of the bagging film (both sides should have the release film on the top of the material stack). 5. The following operation should be performed while wearing a dust mask. Cut the fiber weave to the desired size (as many layers as required for the lay-up). The fiber weaves are prone to shredding once cut; minimize handling and time between cutting and epoxy impregnation to prevent damage to the weave. The following operations shall be performed under the fume hood in Bray 113. Use a flat tray to transport the bagging materials and fiber weave from Bray 109 to Bray 113. Take care not to distort or shred the weave while handling. Make sure the fume hood is turned on and the sash is lowered halfway down to ensure proper circulation. 6. In a paper mixing cup, mix 100 parts epoxy resin with 27 parts epoxy hardener, by weight on a digital scale. Make sure to prepare enough epoxy to impregnate the entire laminate lay-up. Mix the resin and hardener using a wooden stirrer for at least 1 minute. Scrape the sides and bottom of the cup with the wooden stirrer to ensure proper mixing. 7. Place the first layer of the composite laminate on one of the release film surfaces. Center the weave over the film.PDF Image | Laminate Vacuum Bagging Procedure

PDF Search Title:

Laminate Vacuum Bagging ProcedureOriginal File Name Searched:

Composite-Laminate-Vacuum-Bagging-Procedure.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |